Rail-mounted regeneration rice harvesting device

A harvesting device and a technology for regenerated rice, which are applied in the directions of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of increasing the yield of regenerated rice, affecting the yield of regenerated rice, reducing the number of effective ears, etc., so as to improve the number of effective ears, fertilizer The effect of reduced dosage and pesticide dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The track-type ratooned rice harvesting device involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0017]

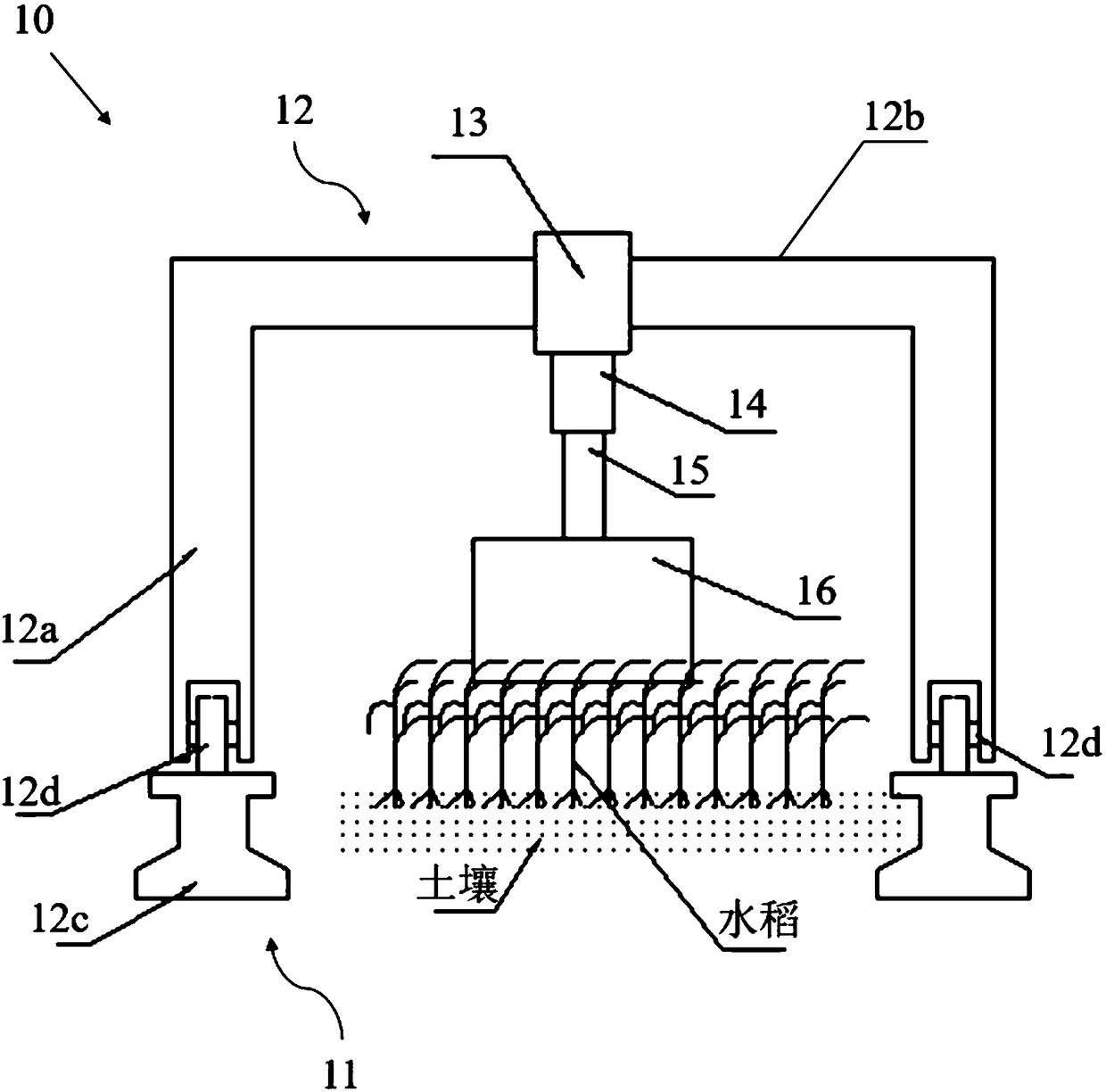

[0018] Such as figure 1 As shown, the track-type ratooned rice harvesting device 10 includes a guide rail assembly 11, a door frame 12, a sliding assembly 13, a rotating member 14, a lifting member 15, a harvesting assembly 16, and a controller.

[0019] The guide rail assembly 11 comprises two sets of guide rails 11a laid in parallel and equally spaced on the field ridge.

[0020] The door frame 12 is disposed on the guide rail assembly 11, and it includes two legs 12a, a beam 12b, a roller 12c, and two rollers 12d. The two left and right leg portions 12a respectively correspond to two sets of guide rails 11a. The beam 12b is erected on the two leg parts 12a. The two rollers 12c are respectively installed on the bottom ends of the two legs 12a via two rollers 12d, and can move back and forth (lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com