Plasma synthetic jet combined actuator

A technology for synthesizing jet and plasma, applied in the field of ions, can solve the problems of jet exciter not considering versatility and adaptability, destroying the aerodynamic shape of the application object, irregular structure and shape, etc., to save installation space, simple structure and high performance reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

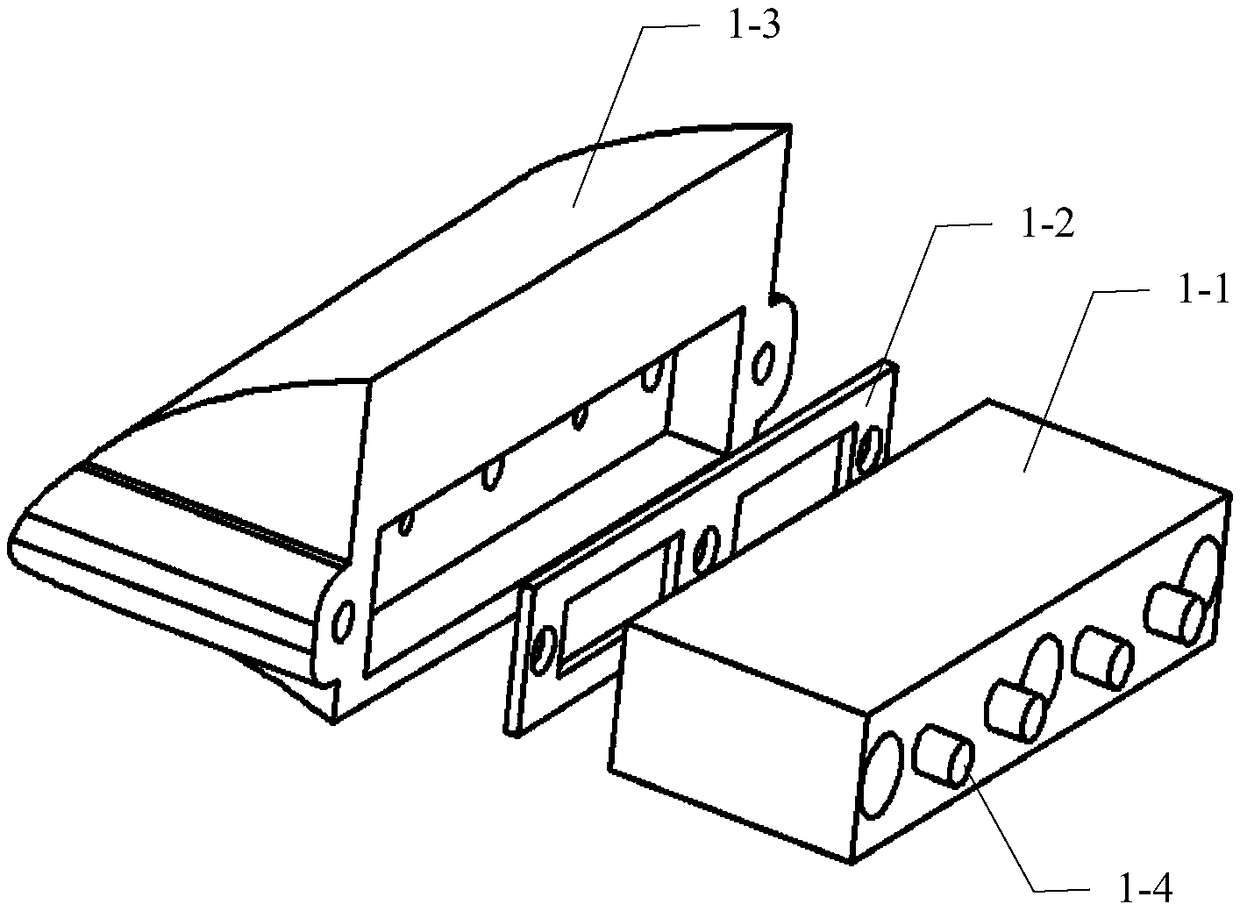

[0017] figure 1 Shown is a structural diagram of a dual-cavity plasma synthetic jet combined exciter of the present invention, the exciter consists of an exciter base 1-1, a rubber pad 1-2, an exciter cover plate 1-3 and a discharge electrode 1-4 The exciter base 1-1 and the exciter cover plate 1-3 are fixed by bolts, and the rubber pad 1-2 is placed between the two to ensure that the exciter base 1-1 and the exciter cover plate are connected when the exciter is working. 1-3 The airtightness of the connection.

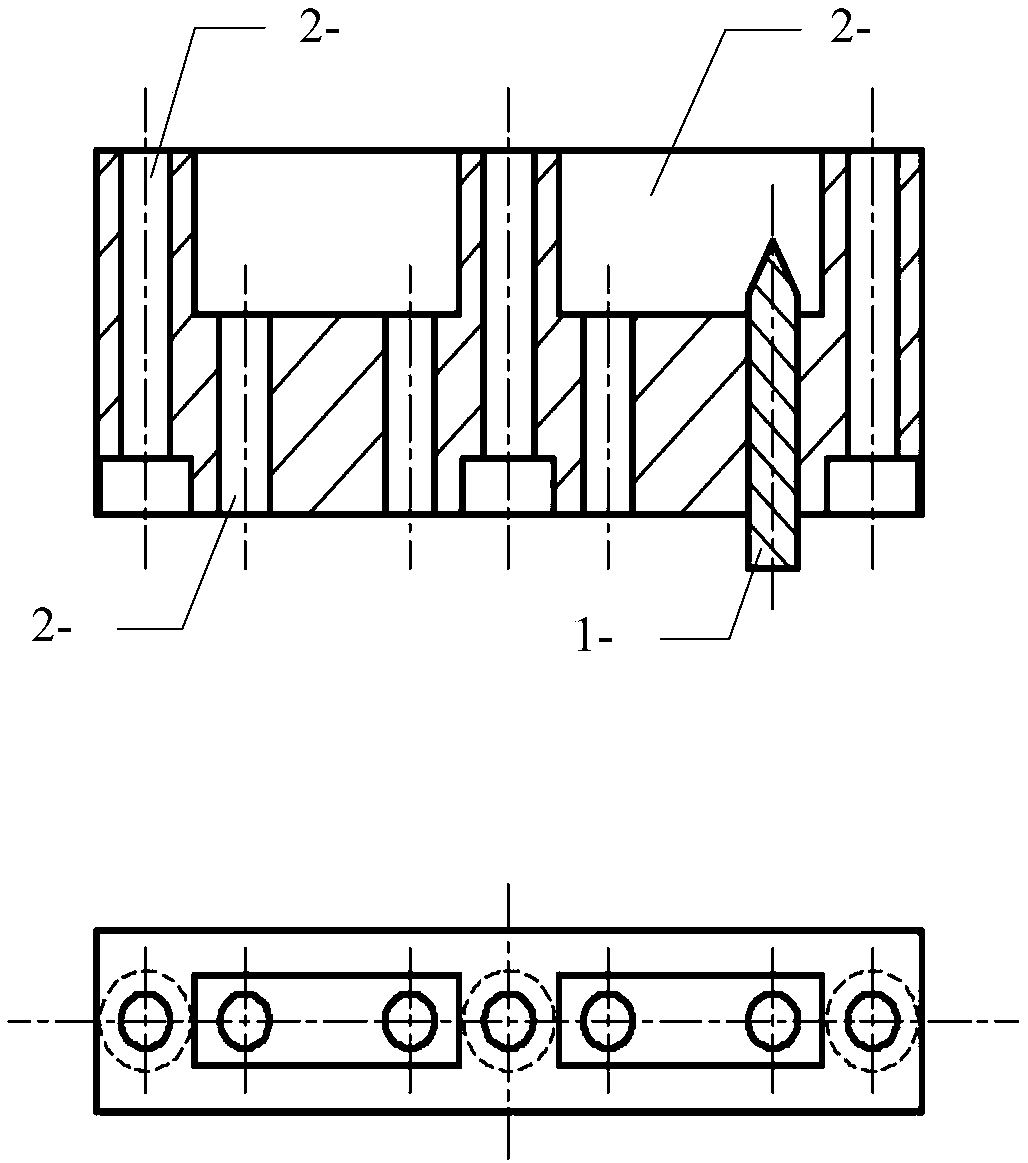

[0018] figure 2 Shown is the exciter base of the present invention (see figure 1 1-1) in the structural diagram, its structure includes the electrode insertion hole 2-1, the countersunk bolt through hole 2-2 and the discharge chamber 2-3. The exciter base 1-1 is made of alumina ceramics, two discharge cavities 2-3 are arranged side by side, and the volume of each cavity is 800mm 3 . The electrode insertion hole 2-1 is used for inserting the discharge electrode in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com