High-potential lithium ion battery cathode material LiNi<0.5-x>MxMn<1.5-y>SiyO4 and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electrochemical cycle performance, and achieve poor stability, easy operation, and easy bulk phase doping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

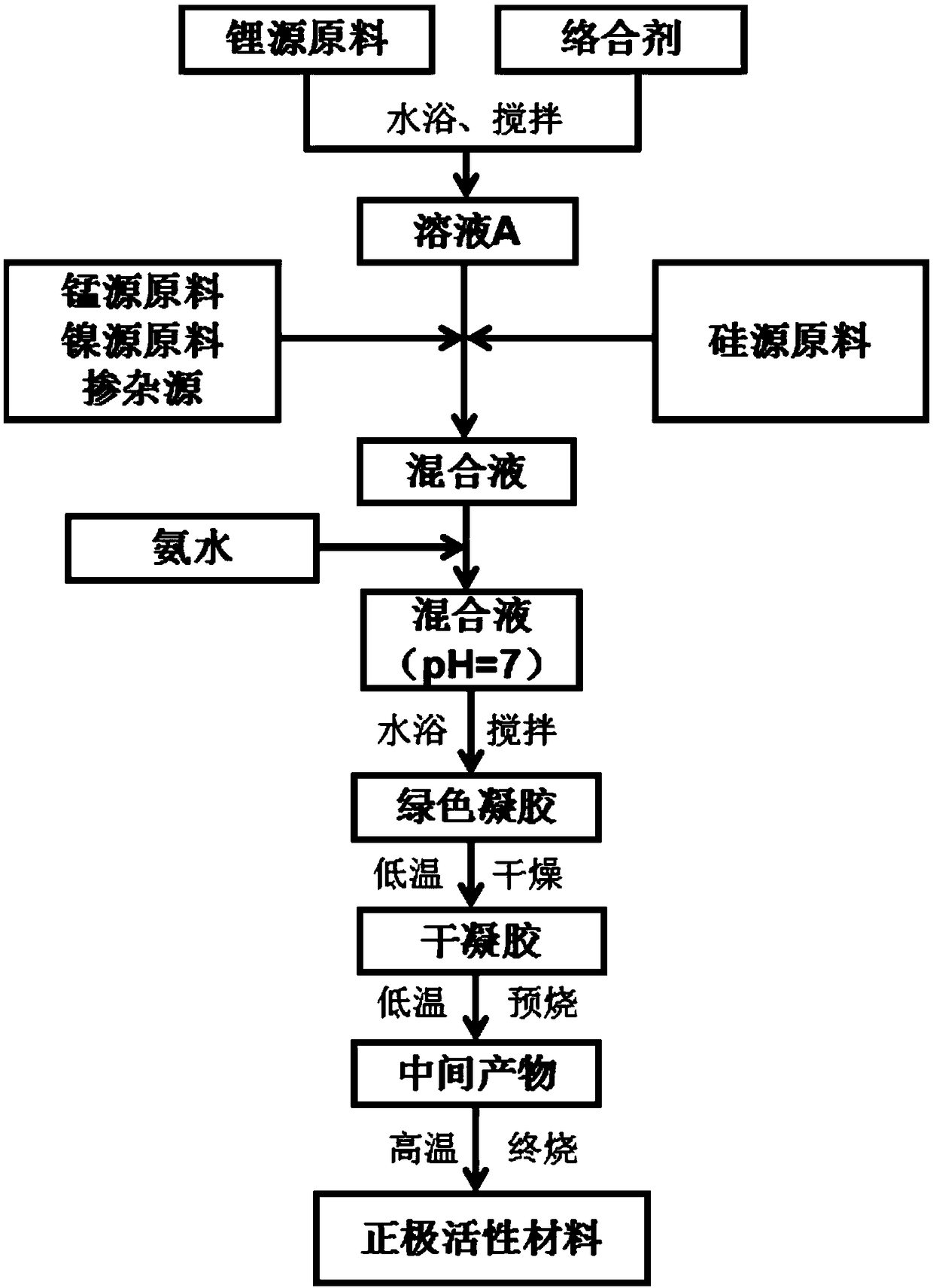

Method used

Image

Examples

Embodiment 1

[0037] Dissolve 0.0315mol (1.3217g) lithium hydroxide and 0.0394mol complexing agent (citric acid + triethanolamine + PEG) in an appropriate amount of deionized water, and stir in a 50°C water bath to make it completely dissolved to obtain solution A; Dissolve 0.0441mol (10.8085g) manganese acetate, 0.0141mol (3.5089g) nickel acetate and 0.0009mol (0.2308g) magnesium nitrate in deionized water to prepare mixed salt solution B; add 0.0009mol (0.1875g) ethyl orthosilicate Disperse the ester in an appropriate amount of absolute ethanol to obtain an ethanol solution C of ethyl orthosilicate.

[0038] Add mixed salt solution B and ethyl orthosilicate ethanol solution C to solution A slowly and dropwise at the same time, with constant stirring, adjust the pH to 7 with ammonia water, stir for 30 minutes and then raise the temperature to 80°C, and continue stirring until green Then, the green gel obtained is dried in a blast drying oven at 110°C for 24 hours to obtain a dry gel, and the ...

Embodiment 2

[0041] Dissolve 0.0315mol (1.3217g) lithium hydroxide and 0.0394mol complexing agent (citric acid + triethanolamine + PEG) in an appropriate amount of deionized water, and stir in a 50°C water bath to completely dissolve to obtain solution A; Dissolve 0.0441mol (10.8085g) manganese acetate, 0.0141mol (3.5089g) nickel acetate and 0.0009mol (0.2308g) magnesium nitrate in deionized water to prepare mixed salt solution B; add 0.0009mol (0.1875g) ethyl orthosilicate The ester is dispersed in an appropriate amount of absolute ethanol to obtain an ethanol solution C of ethyl orthosilicate.

[0042] Add mixed salt solution B and ethyl orthosilicate ethanol solution C slowly and dropwise to solution A at the same time, with constant stirring, adjust the pH to 7 with ammonia water, stir for 30 minutes and then raise the temperature to 80°C, and continue stirring until green Gel; then dry the obtained green gel in a blast drying oven at 110°C for 24 hours to obtain a dry gel, and put the dr...

Embodiment 3

[0045] Dissolve 0.0315mol (1.3217g) lithium hydroxide and 0.0394mol complexing agent (citric acid + triethanolamine + PEG) in an appropriate amount of deionized water, and stir in a 50°C water bath to make it completely dissolved to obtain solution A; Dissolve 0.0441mol (10.8085g) manganese acetate, 0.0141mol (3.5089g) nickel acetate and 0.0009mol (0.00702g) ammonium metavanadate in an appropriate amount of deionized water to obtain suspension B; add 0.0009mol (0.1875g) ortho silicon Ethyl acid was dispersed in an appropriate amount of absolute ethanol to obtain an ethanol solution C of ethyl orthosilicate.

[0046] Add the B suspension and the ethyl orthosilicate alcohol solution C dropwise to the A solution at the same time, and heat it in a water bath at 50°C with constant stirring, adjust the pH to 7 with ammonia water, and stir until the mixture becomes clear. Afterwards, the water bath was heated to 80°C, and stirring was continued to evaporate the water until a green gel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com