Preparation method of MXn film and application

A thin film and dispersion technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unsuitable QLED device film formation, complex preparation methods, and harsh environmental requirements, and achieve balanced injection. The method is simple, reliable, and safe. sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The embodiment of the present invention provides a MX n The film preparation method includes the following steps:

[0023] S01. Provide MX m Powder, the MX m The powder is dispersed in the solvent to obtain MX m Dispersions;

[0024] S02. In the MX m Add (NH 4 ) 2 X, stirring or ultrasonic processing until a clear mixed solution is obtained;

[0025] S03. Heat and stir the mixed solution to obtain a polysulfide precursor solution, and then deposit the film layer by solution processing;

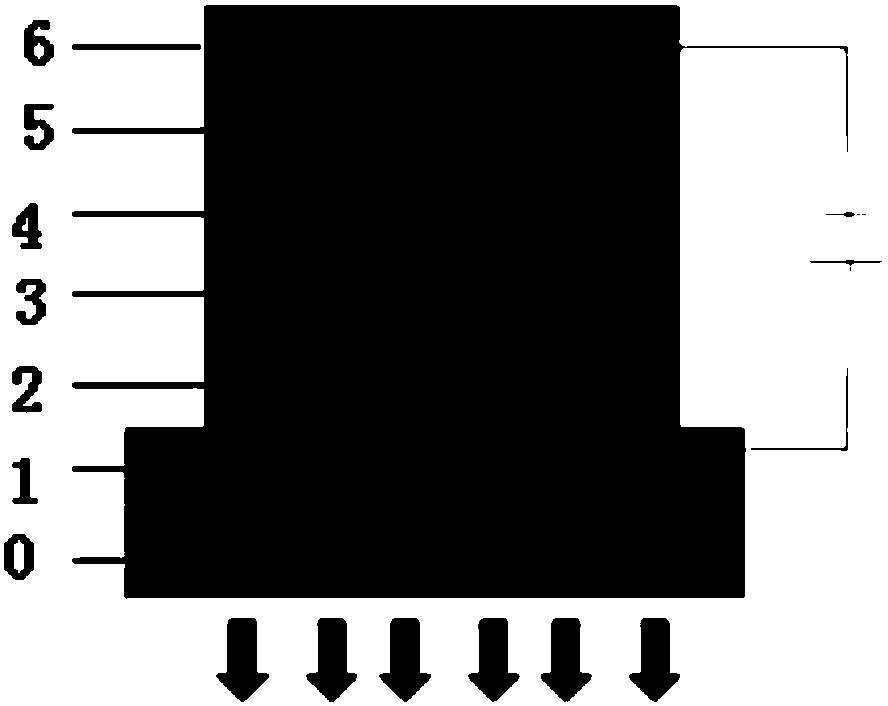

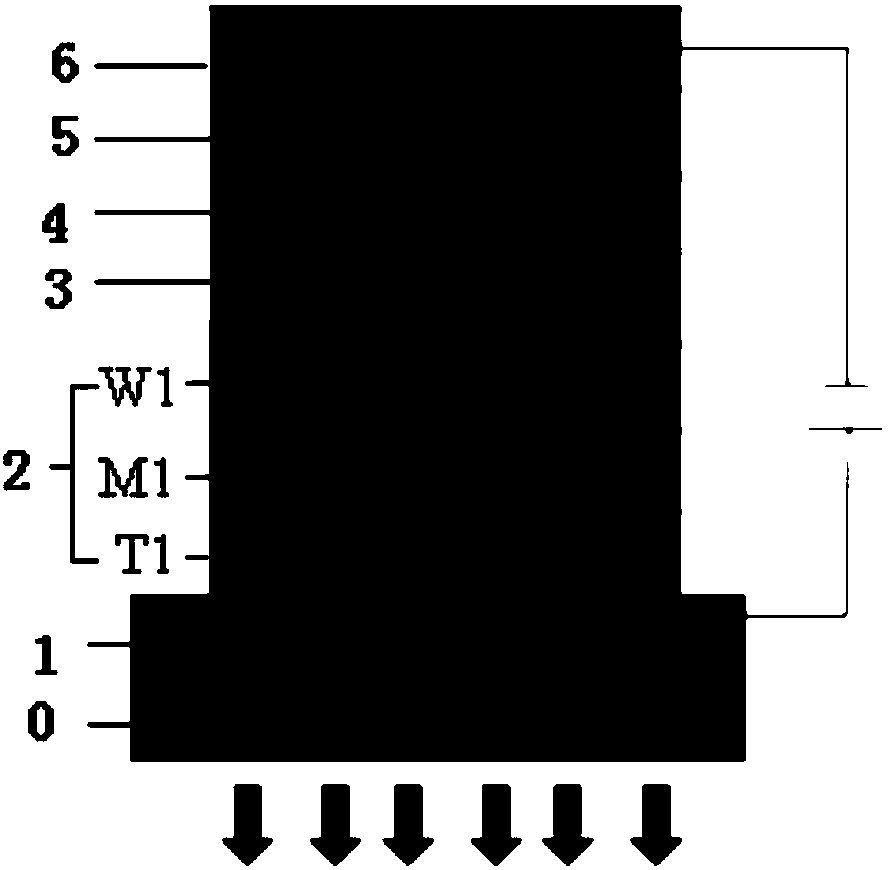

[0026] S04. After the film is annealed at 80-120°C, it is heated at 250-300°C in a reducing or inert atmosphere to obtain MX n film,

[0027] Where the MX m , (NH 4 ) 2 X, in, X is at least one of S and Se; the MX m , MX n Where M is one of Mo, W, V, Nb, Ta, the MX m Among them, the value range of m is 2≤m≤3; the MX n Among them, the value range of n is 2≤n﹤3, and n≤m.

[0028] Specifically, in the above step S01, the MX m The powder is a metal sulfide powder, that is, M is one of Mo, W, V, Nb, an...

Embodiment 1

[0058] A preparation method of polysulfide precursor solution includes the following steps:

[0059] 10mmol MoS 3 Dissolve in 10ml water, add 10mmol(NH 4 ) 2 S, after stirring until it is completely dissolved, heat and stir at 60°C for 1 h, and mark its solution as M1.

Embodiment 2

[0061] A preparation method of polysulfide precursor solution includes the following steps:

[0062] 10mmol WS 3 Dissolve in 10ml water, add 10mmol(NH 4 ) 2 S, after stirring until it is completely dissolved, heat and stir at 60°C for 1 h, and mark its solution as W1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com