Clamping device and slicer with same

A technology of clamping device and slicer, which is applied in the direction of measuring devices, sampling devices, clamps, etc., can solve problems such as wear and loss of clamping functions, and achieve the effects of reducing contact area, prolonging service life, and improving self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

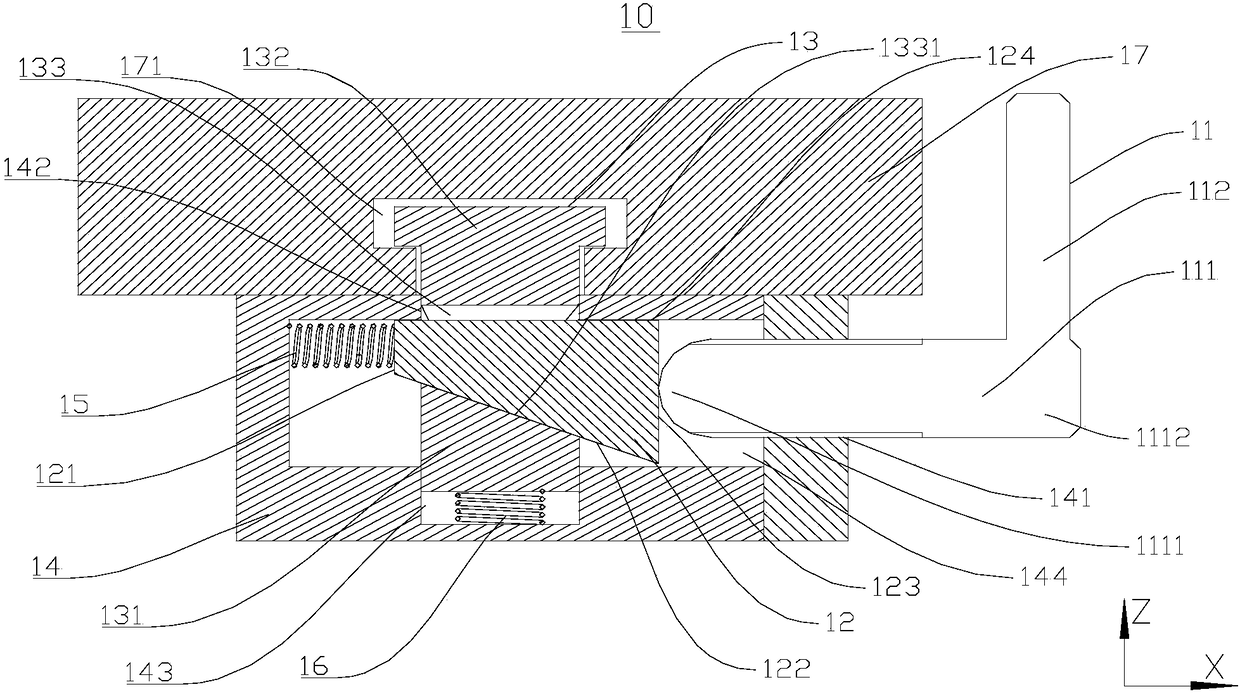

[0095] Preferred embodiments of the present disclosure will be described below with reference to the drawings. It should be noted that the terms "upper", "lower", "left", "right", "front", "rear" and similar expressions used herein are for the purpose of illustration only and not to limit the present disclosure.

[0096] figure 1 A microtome 100 known in the prior art is shown. Such as figure 1 As shown, the microtome 100 includes a blade holder 101 and a mounting seat 102 . Wherein, the blade frame 101 is connected to the mounting base 102 .

[0097] figure 2 show figure 1 The blade holder 101 of the microtome 100. Such as figure 2 As shown, the blade holder 101 includes a base 1 , a microtome blade 2 , a base 3 , a pressure plate 4 and a segmented curved member 5 . Wherein the base body 3 has an abutment surface, a pressure plate 4 is attached to the base body 3, the pressure plate 4 can be adjusted relative to the base body 3 to clamp the microtome blade 2 receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com