Improved solid-liquid mixture treatment system

一种固液混合、处理系统的技术,应用在促进固体材料干燥的初步处理、污泥处理、干燥固体物料等方向,能够解决干燥效果不好、干燥效率低、结构复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

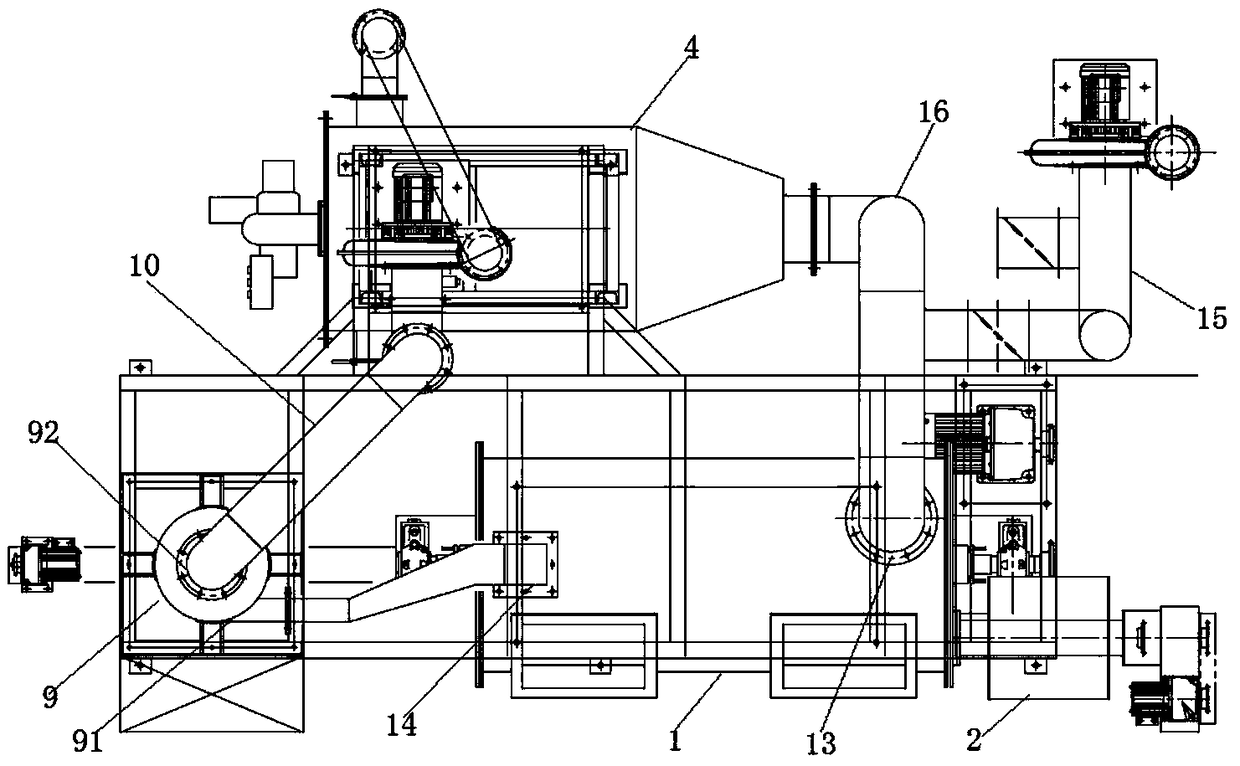

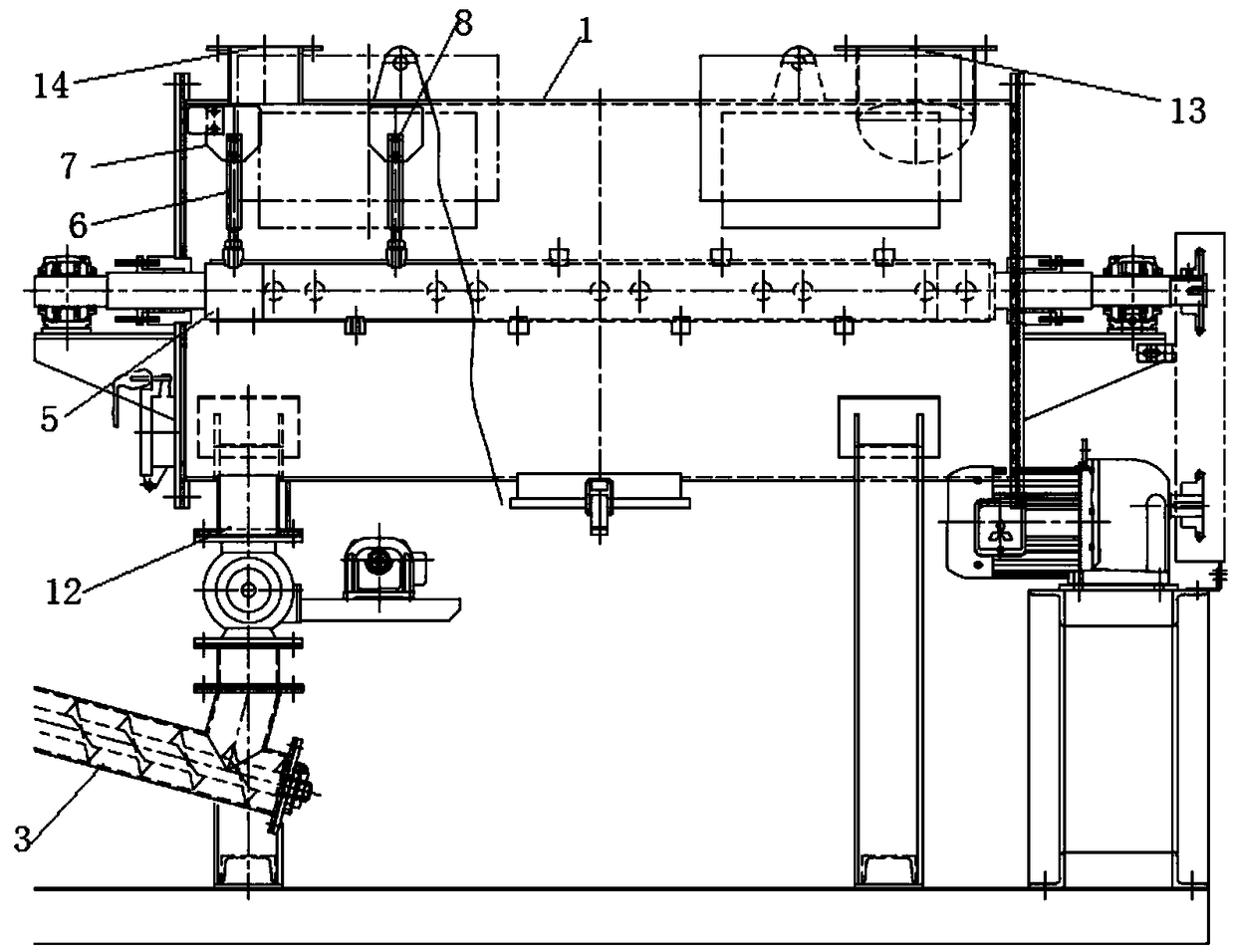

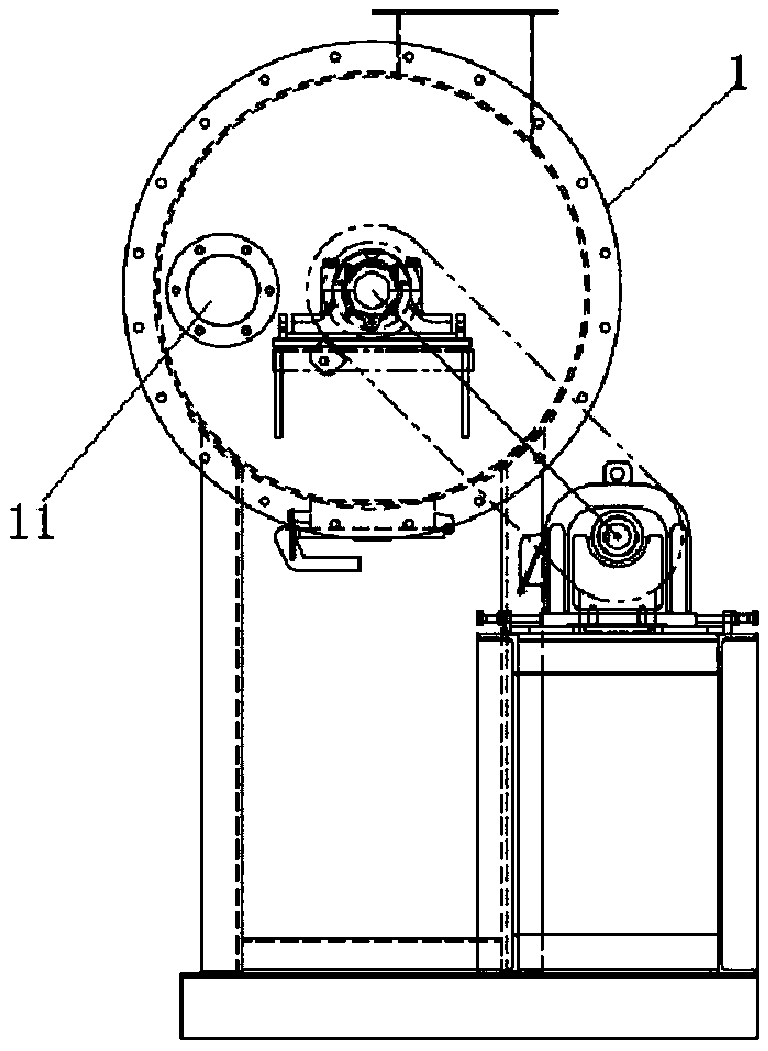

[0044] Such as Figure 5 As shown, the present embodiment provides an improved solid-liquid mixture processing system, including

[0045] The transmission device has a two-stage transmission surface, the first-stage transmission surface is located above the side of the second-stage transmission surface, the first-stage transmission surface 200 and the second-stage transmission surface 300 are connected by a transition device 500, and the first-stage transmission surface The height between 200 and the second-stage transmission surface 300 is greater than 100cm, and the transmission device can transport the solid-liquid mixed sludge from the head end of the first-stage transmission surface to the tail end of the first-stage transmission surface, and through the transition The device 500 is introduced to the second-level transmission surface, and transported from the head end of the second-level transmission surface to the tail end of the second-level transmission surface;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com