Damping fabricated underground pipe gallery and mounting method

A technology of underground pipe gallery and installation method, applied in the field of pipe gallery, can solve the problems of no dust removal facilities, poor protection and shock absorption effect, no environmental detection mechanism, etc., and achieve good support, protection, installation, and good load-bearing support. The effect of stability, damping and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

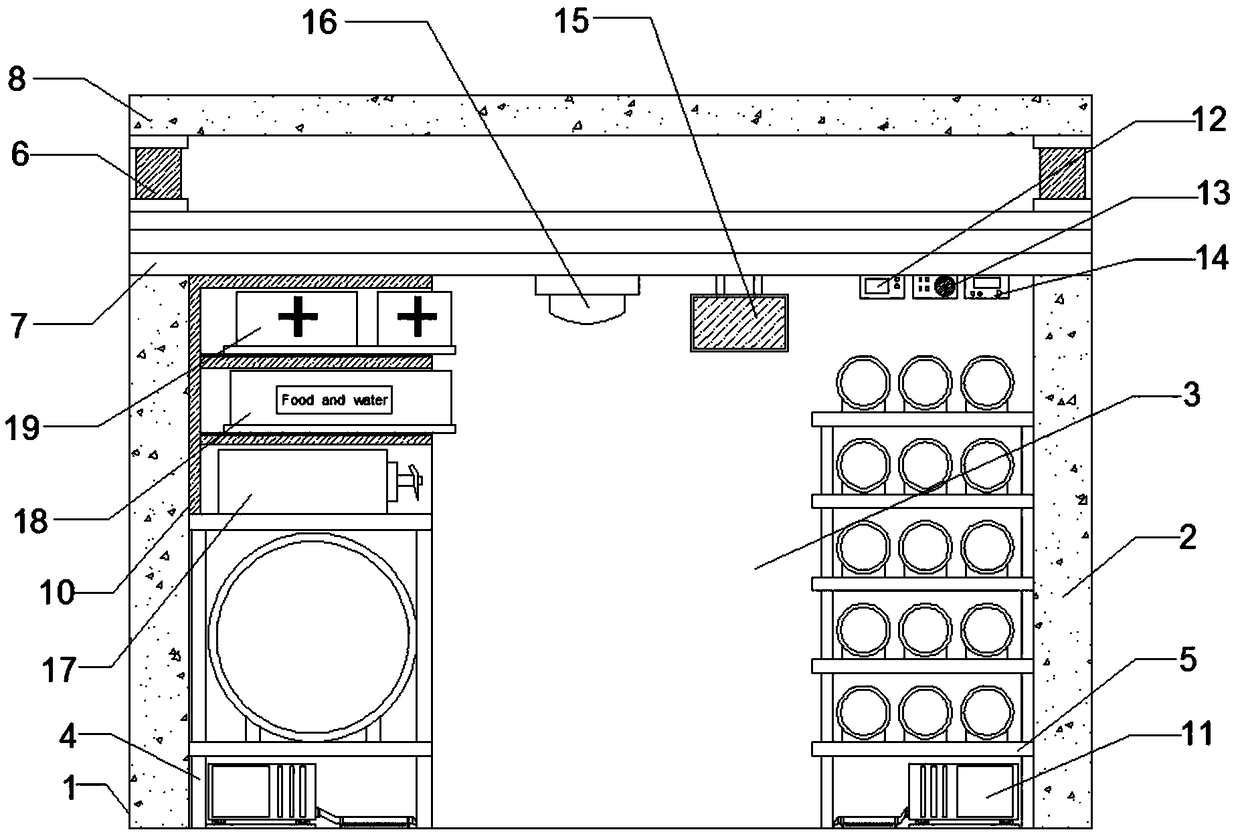

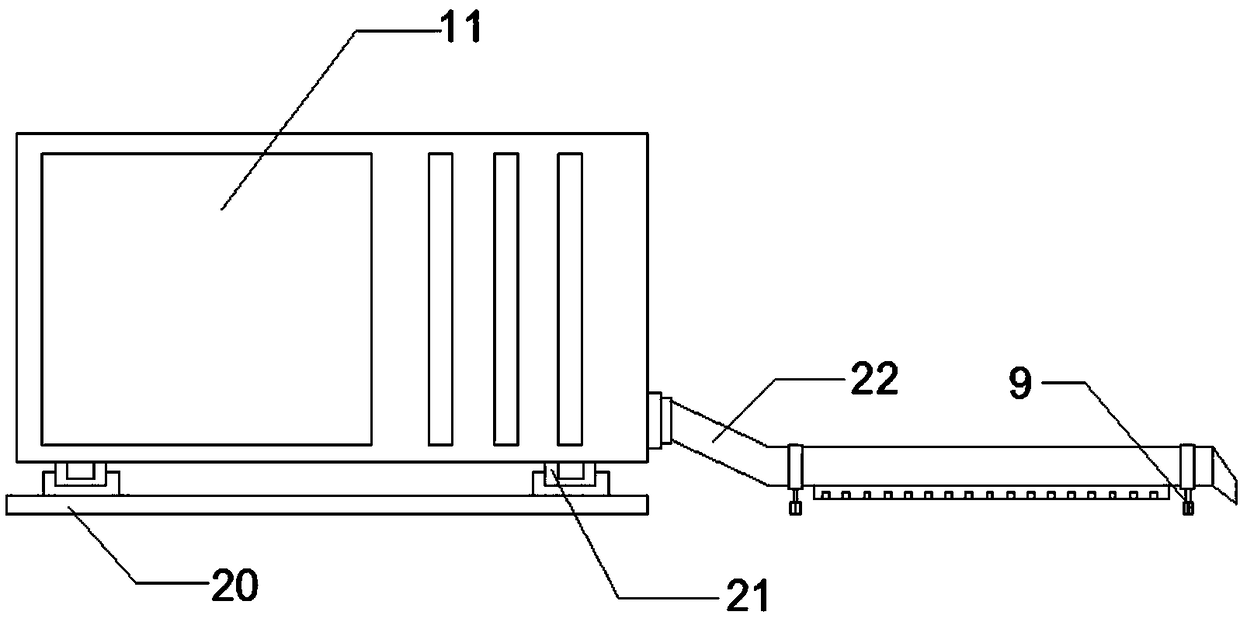

[0029] Such as Figure 1-2 As shown, a shock-absorbing assembled underground pipe gallery and its installation method include a pipe gallery 1, a load-bearing column 2, a walkway 3, a first pipe frame 4 and a second pipe frame 5, and the pipe gallery 1 includes the side wall of the pipe gallery 1. The roof of the pipe gallery and the bottom plate of the pipe gallery are made of 300mm-thick bidirectional double-row concrete slabs; both sides of the pipe gallery 1 are built with foundation piles to build load-bearing columns 2, and it is preferred to use a drill with a diameter of 600mm and a pile edge spacing of 4 meters. The load-bearing column 2 is made of cast-in-place piles, and embedded parts are set between the pipe gallery 1 and the load-beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com