An outrigger type steel pipe pile and its construction method

A steel pipe pile and arm type technology, which is applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of low bearing capacity and smooth side wall, and achieve the effect of improving strength, convenient operation and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

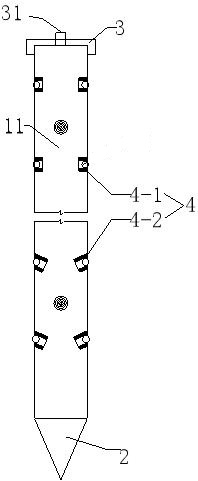

[0040]Such asFigure 1-3 Shown:

[0041]An outrigger steel pipe pile, comprising a pile body 1 and a pile tip 2. The pile body 1 is a steel pipe structure, the pile tip 2 is a conical structure with a closed bottom, and the pile body 1 and the pile tip 2 are integrally formed The inside of the pile body 1 is a cavity structure, and the pile body 1 is connected with an outrigger 4 that can extend to the outside of the pile body 1 and insert into the soil; after the outrigger is inserted into the soil, the steel pipe pile is greatly increased The lateral friction resistance and bearing capacity meet the requirements of building foundation reinforcement and expand the scope of application;

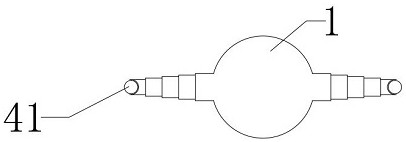

[0042]The extension arm 4 is a hollow structure with one end closed and the other end open, and the cavity communicates with the hollow structure through an opening; the extension arm 4 includes a first extension arm 4-1 and a first extension arm 4-1 arranged perpendicular to the pile body 1 The second ex...

Embodiment 2

[0054]Embodiment 2 is the construction method of embodiment 1. The specific method is: a construction method of outrigger steel pipe pile, and the specific steps are as follows:

[0055]1) Provide an outrigger steel pipe pile as described in Example 1;

[0056]2) Set the line to determine the pile position, use the lifting ring to suspend the outrigger steel pipe pile directly above the pile position, and aim the pile tip at the middle position of the pile position;

[0057]3) Start the pile driver and slowly insert the outrigger steel pipe pile into the foundation;

[0058]4) When the pile body reaches a predetermined depth, cover the pile cover 3, and use a high-pressure air pump to inject high-pressure gas into the cavity through the high-pressure inflation hole 31 on the pile cover 3, and stabilize the pressure for 13-18 minutes to ensure the extension Arm 4 is fully extended and inserted into the soil;

[0059]5) Remove the pile cover 3 and the high-pressure air pump, insert a grouting pipe i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com