A magnesium-based metal conversion coating with high corrosion resistance and surface functionalization and its preparation method

A technology with surface functionalization and high corrosion resistance, applied in the field of medical materials, it can solve the problems of affecting the growth of surrounding tissues, excessive corrosion rate, stress fracture, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

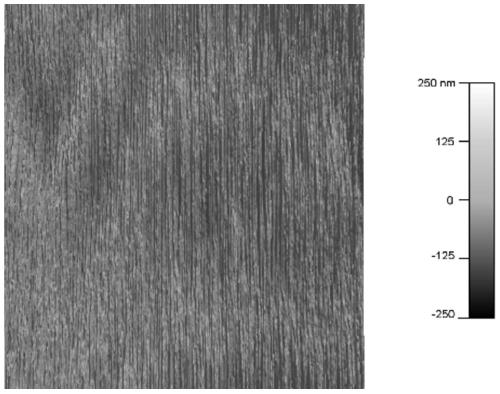

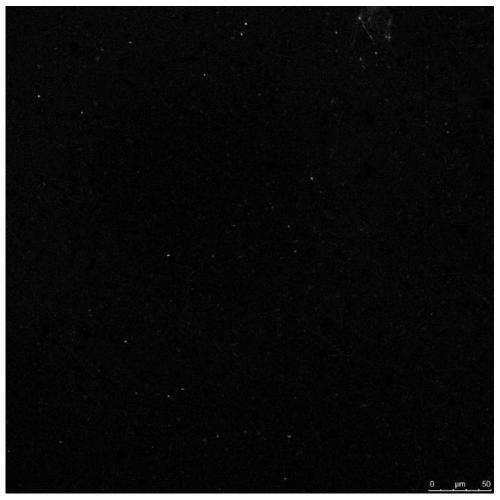

Image

Examples

Embodiment 1

[0030] A method for preparing a magnesium-based metal conversion coating with high corrosion resistance and surface functionalization, comprising the following steps:

[0031] (1) polishing, cleaning and drying the pure magnesium material to be modified;

[0032] (2) Place the product obtained in step (1) in a polyethyleneimine solution with a concentration of 0.01 mM and a pH value of 7.4, react at 4°C for 2 min, then take it out, and wash it with deionized water for 3 times;

[0033] (3) The product obtained in step (2) was placed in a mixed solution of epicatechin and heparan sulfate with a concentration of 0.2mM and a pH value of 7.5, reacted at 10°C for 5min, then took it out, and washed it with deionized water for 3 times; wherein, the mol ratio of epicatechin and heparan sulfate is 1:2;

[0034] (4) Using the product obtained in step (3) as a substrate, repeat the process described in steps (2) to (3) 60 times, dry it with nitrogen, and then store it in a vacuum oven t...

Embodiment 2

[0036] A method for preparing a magnesium-based metal conversion coating with high corrosion resistance and surface functionalization, comprising the following steps:

[0037] (1) Polishing, cleaning and drying the magnesium-zinc-manganese alloy to be modified;

[0038] (2) Place the product obtained in step (1) in a polyhexyl violet nitrile solution with a concentration of 0.01 mM and a pH value of 7.5, react at 5° C. for 2 min, then take it out, and wash it with deionized water for 3 times;

[0039] (3) Place the product obtained in step (2) in a mixed solution of epigallocatechin gallate and dermatan sulfate with a concentration of 0.02mM and a pH value of 7.8, react at 15°C for 5min, then take it out, and use it Ionized water was washed 3 times; wherein, the mol ratio of epigallocatechin gallate and dermatan sulfate was 1:1;

[0040] (4) Using the product obtained in step (3) as a substrate, repeat the process described in steps (2) to (3) 3 times, dry with nitrogen, and ...

Embodiment 3

[0042] A method for preparing a magnesium-based metal conversion coating with high corrosion resistance and surface functionalization, comprising the following steps:

[0043] (1) Polish, clean and dry the WE43 magnesium alloy that needs to be modified;

[0044] (2) Place the product obtained in step (1) in a chitosan solution with a concentration of 0.01 mM and a pH value of 7.4, react at 5° C. for 2 min, then take it out, and wash it with deionized water for 3 times;

[0045] (3) Put the product obtained in step (2) in a mixed solution of epicatechin gallate and chondroitin sulfate with a concentration of 0.05mM and a pH value of 7.2, react at 10°C for 5min, then take it out, and use deionized Water was washed 3 times; wherein, the mol ratio of epicatechin gallate and chondroitin sulfate was 1.5:2;

[0046](4) Using the product obtained in step (3) as a substrate, repeat the process described in steps (2) to (3) 5 times, dry with nitrogen, and then store it in a vacuum oven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com