A kind of high anti-creep and anti-corrosion material and the method for using the material to prepare shelling hammer head

A technology of shelling hammer and corrosion-resistant materials, which is applied in the field of aluminum smelting, can solve the problems of high price, high price, insufficient electrochemical corrosion resistance and impact resistance, and achieve high labor intensity, high hardness and short service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: A high creep and corrosion resistant material, comprising the following components by weight percentage: C 0.24%, Cr 24%, Ni 10.7%, Mn 1.5%, W 2.6%, Si 1.0%, B 0.002%, P 0.04%, S 0.008%, and the balance is Fe.

[0030] A kind of method that utilizes high anti-creep anti-corrosion material to prepare shelling hammer head, comprises the following steps:

[0031] The first step: smelting, using the AOD refining method to smelt high creep and corrosion resistant materials.

[0032] The second step: producing steel ingots, casting the molten steel that has been smelted through billet continuous casting machines or producing billet steel ingots by die casting, and the cross-sectional size of the billet steel ingots is 250mm, and the weight of the steel ingots is 351.5Kg.

[0033] Step 3: Forging. During forging, the initial forging temperature is 1260°C during forging, and the temperature during forging is lower than 850°C. It should be heated in time. Two-stage ...

Embodiment 2

[0038] Example 2: A high creep and corrosion resistant material, comprising the following components by weight percentage: C 0.18%, Cr 23%, Ni 12%, Mn 1.0%, W 1.8%, Si 1.2%, B 0.001%, P 0.03%, S 0.01%, and the balance is Fe.

[0039] A kind of method that utilizes high anti-creep anti-corrosion material to prepare shelling hammer head, comprises the following steps:

[0040] The first step: smelting, using the AOD refining method to smelt high creep and corrosion resistant materials.

[0041] The second step: producing steel ingots, casting the molten steel that has been smelted through billet continuous casting machines or producing billet steel ingots by die casting, and the cross-sectional size of the billet steel ingots is 160mm, and the weight of the steel ingots is 296Kg.

[0042] Step 3: Forging. During forging, the initial forging temperature is 1255°C during forging, and the temperature during forging is lower than 850°C. It should be heated in time. The two-stage for...

Embodiment 3

[0047] Embodiment 3: A kind of high anti-creep anti-corrosion material, comprises following composition by weight percentage: C 0.29%, Cr 25%, Ni 9.5%, Mn 2.0%, W 3.4%, Si 0.7%, B 0.004%, P 0.025%, S 0.006%, and the balance is Fe.

[0048] A kind of method that utilizes high anti-creep anti-corrosion material to prepare shelling hammer head, comprises the following steps:

[0049] The first step: smelting, using the AOD refining method to smelt and smelt high creep and corrosion resistant materials.

[0050] The second step: producing steel ingots, casting the molten steel that has been smelted through billet continuous casting machines or producing billet steel ingots by die casting, and the cross-sectional size of the billet steel ingots is 360 mm, and the weight of the steel ingots is 407 Kg.

[0051] The third step: hot rolling, the initial rolling temperature is 1300 ° C, the final rolling temperature is 1000 ° C, hot rolling to a bar with a cross-sectional size of 90 mm...

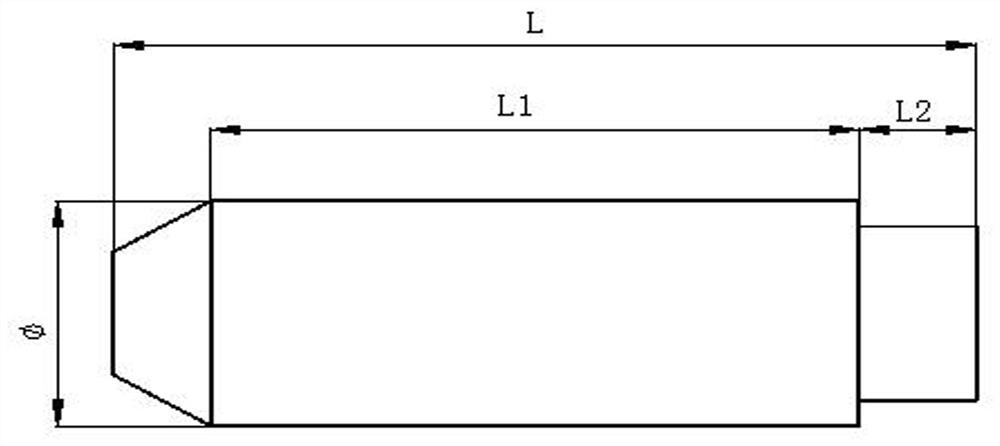

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com