Preparation method of graphene

A technology of graphene and graphene powder, which is applied in the direction of graphene, bulk chemical production, nano-carbon, etc., can solve the problems of large damage to graphene sheets, affecting the modification and application of polymer materials, and reducing the performance of graphene. Achieve good modification effect, lower oxygen content, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

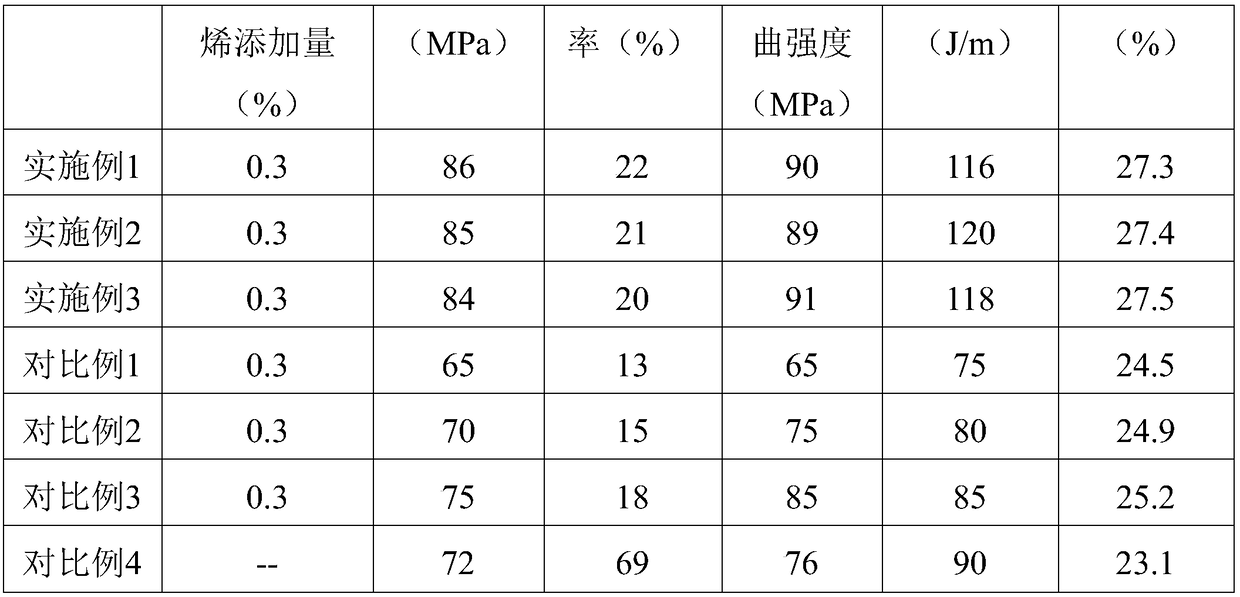

Examples

Embodiment 1

[0028] A kind of graphene preparation method of the present invention adopts the following steps:

[0029] Step 1, peel off 100kg of graphite powder by supercritical carbon dioxide method, add 500kg of water to the obtained graphite powder, and crush the obtained slurry through a homogenizer. The pressure of the homogenizer is 90MPa. , emulsified composite dispersion method for processing, after the dispersion is dried, the drying temperature is 150 ° C.

[0030] Step 2, add the dry product to 100kg of dilute hydrochloric acid for soaking at -10°C, and then add the compound of potassium dichromate and hydroperoxide after 4 hours, wherein 10kg of potassium dichromate and the mass of hydroperoxide 10kg, control the temperature at 10°C, add 400kg of deionized water after 2.5h of reaction, suction filter, wash, and finally dry to obtain graphene oxide powder, the drying temperature is 160°C.

[0031] Step 3, disperse the graphene oxide powder obtained in step 2 in 200kg of dichlo...

Embodiment 2

[0037] Present embodiment 2 a kind of graphene preparation method, adopts the following steps:

[0038] Step 1, 100kg of worm graphite is stripped by supercritical carbon dioxide, the graphite powder obtained is added to 500kg of water, and the obtained slurry is crushed by a homogenizer. The pressure of the homogenizer is 150MPa. The emulsified compound dispersion method is used for processing, and after the dispersion is completed, it is dried by air-flow spray drying, and the drying temperature is 230°C.

[0039] Step 2, add the dry product to 250kg of dilute hydrochloric acid for soaking at 15°C, and then add the compound mixture of potassium dichromate and hydroperoxide after 1 hour, wherein potassium dichromate is 90kg and the compound mixture of hydroperoxide The mass is 5kg, and the temperature is controlled at 85°C. After 6 hours of reaction, 400kg of deionized water is added, suction filtered, washed, and finally the graphene oxide powder is obtained by airflow spray...

Embodiment 3

[0045] Present embodiment 3 a kind of graphene preparation method, adopts the following steps:

[0046] Step 1, 100kg flake graphite is stripped by supercritical carbon dioxide, and the obtained graphite powder is added to 500kg water, and the obtained slurry is crushed by a homogenizer. The pressure of the homogenizer is 110MPa. The emulsified compound dispersion method is used for processing, and after the dispersion is completed, it is dried by air-flow spray drying, and the drying temperature is 170°C.

[0047] Step 2, add the dried product into 120kg of dilute hydrochloric acid for immersion at -1°C, then add the compound mixture of potassium dichromate and hydroperoxide after 2 hours, the quality of potassium dichromate 40kg and hydroperoxide is 9kg, control the temperature at 55°C, add 300kg of deionized water after 3.5h of reaction, filter with suction, wash, and finally obtain graphene oxide powder by airflow spray drying at a drying temperature of 170°C.

[0048] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com