Low-flow-resistance water cannon preventing device for chimney exhaust pipe

A technology of exhaust pipe and low flow resistance, which is applied in the direction of exhaust device, muffler device, propulsion device engine, etc., which can solve the problems of engine blockage, chilling damage and corrosion of the main engine, and achieve good waterproof cannon attack, Smooth exhaust and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

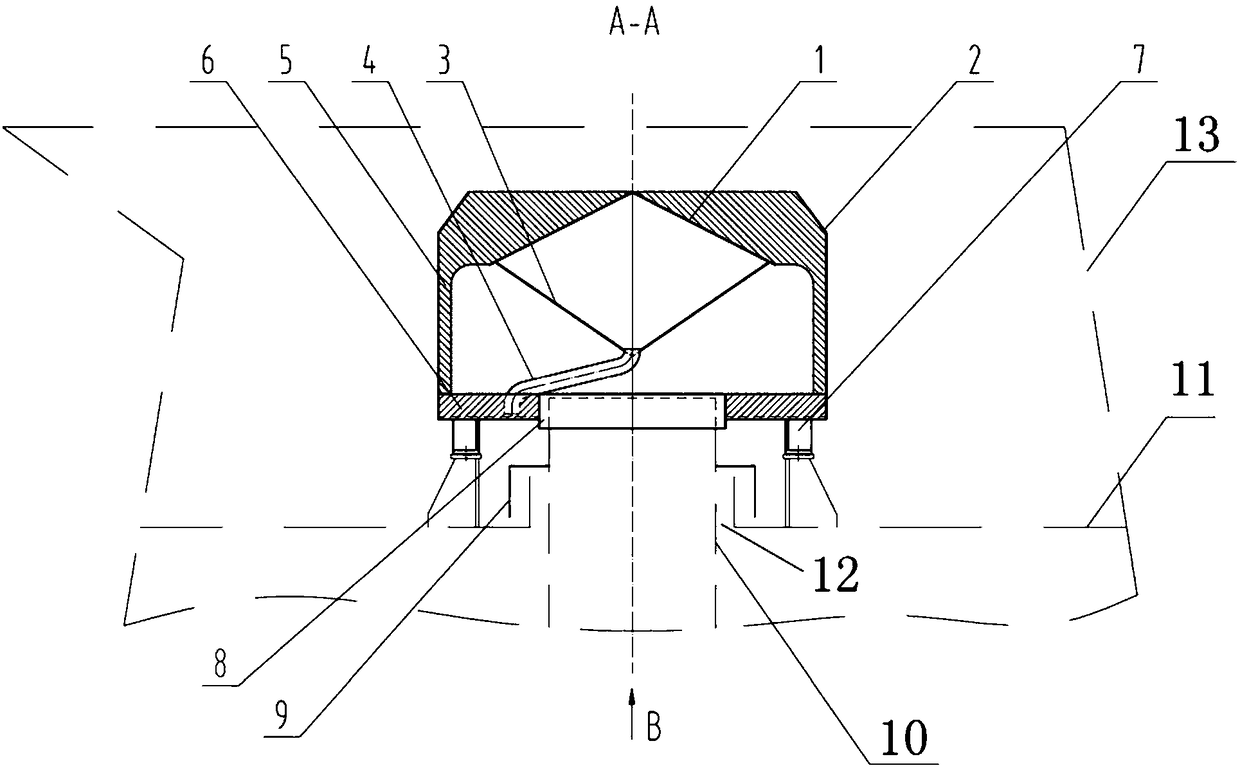

[0018] The following will combine Figure 1 ~ Figure 3 Further detailed description is given to the low-flow resistance water monitor device of the chimney exhaust pipe of the present invention.

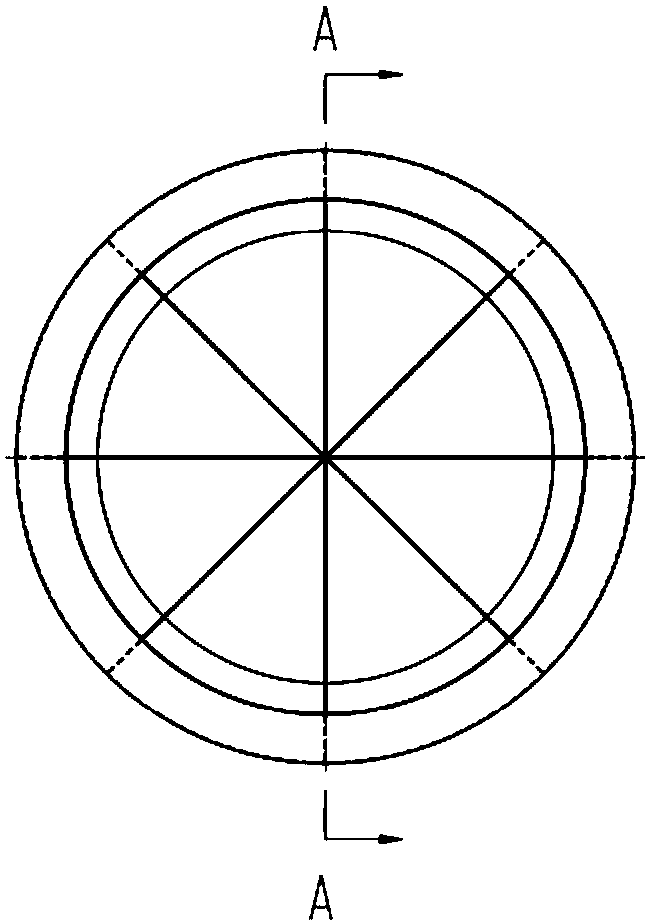

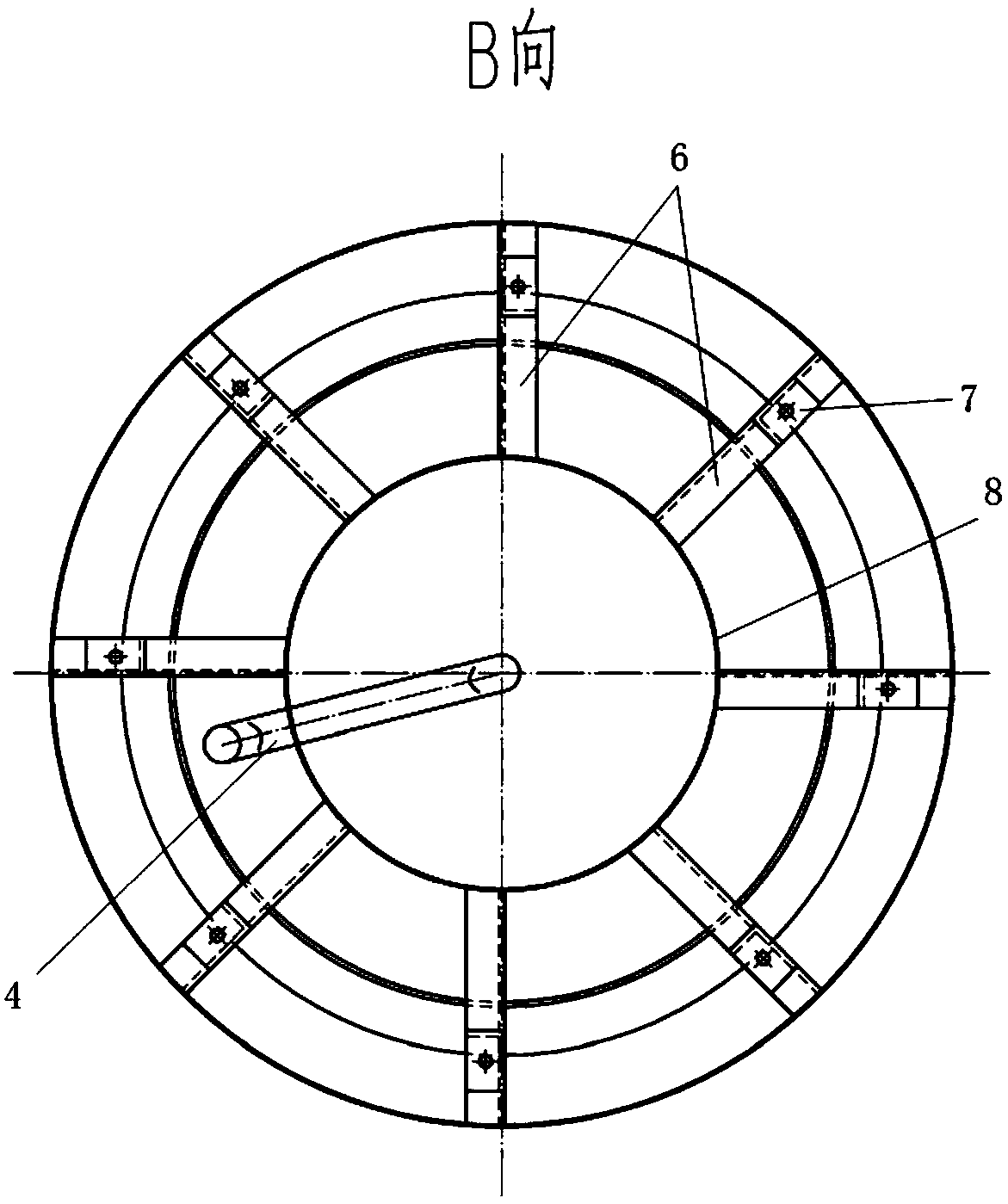

[0019] figure 1 Shown is the top view of the chimney exhaust pipe low flow resistance water monitor device of a preferred embodiment of the present invention; figure 2 yes figure 1 A-A view in ; image 3 yes figure 2 View from direction B in .

[0020] see figure 2 , the chimney sealing plate 11 is arranged on the periphery of the chimney exhaust pipe 10 outlet, the chimney exhaust pipe 10 passes through the chimney sealing plate 11, there is a gap 12 between the chimney sealing plate 11 and the chimney exhaust pipe 10, the chimney sealing plate 11 is along the chimney The edge of the exhaust pipe 10 is provided with a flanging, and the flanging forms a water retaining ring. Both the chimney sealing plate 11 and the chimney exhaust pipe 10 are located in the chimney channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com