Internal-diameter-adjustable plastic extrusion die

An extrusion die and adjustable technology, which is applied to the field of plastic extrusion die with adjustable inner diameter, can solve the problems of inconvenient inner diameter adjustment, inconvenient cleaning of the extrusion structure of the extrusion die, and lack of water cooling and cooling of the extruded plastic finished product. To achieve the effect of convenient twisting, improving efficiency, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

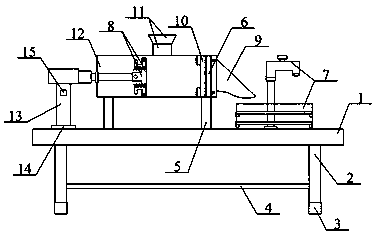

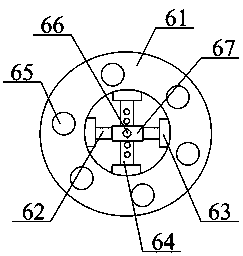

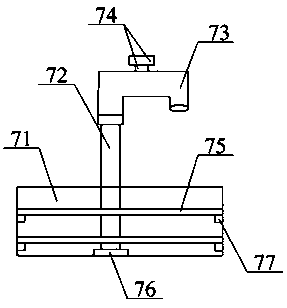

[0037] as attached figure 1 To attach figure 2As shown, the present invention provides a plastic extrusion die with adjustable inner diameter, including an operating table 1, a support column 2, a protective foot cover 3, a reinforced horizontal plate 4, a support frame 5, and an inner diameter adjustable flange structure 6, which can Circulating plastic mold water cooling box structure 7, cleanable top tight extrusion plate structure 8, discharge hopper 9, installation flange 10, feed hopper 11, plastic extrusion mold barrel 12, support seat 13, mounting plate 14 and control switch 15. The support columns 2 are respectively bolted to the four corners of the lower surface of the operating table 1; the protective foot covers 3 are socketed at the lower end of the support column 2; the reinforcement horizontal plate 4 is connected with horizontal screws Between the support column 2 and the inner lower part of the support column 2, it is beneficial to play the role of reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com