Mold for preparing reinforced structure of composite

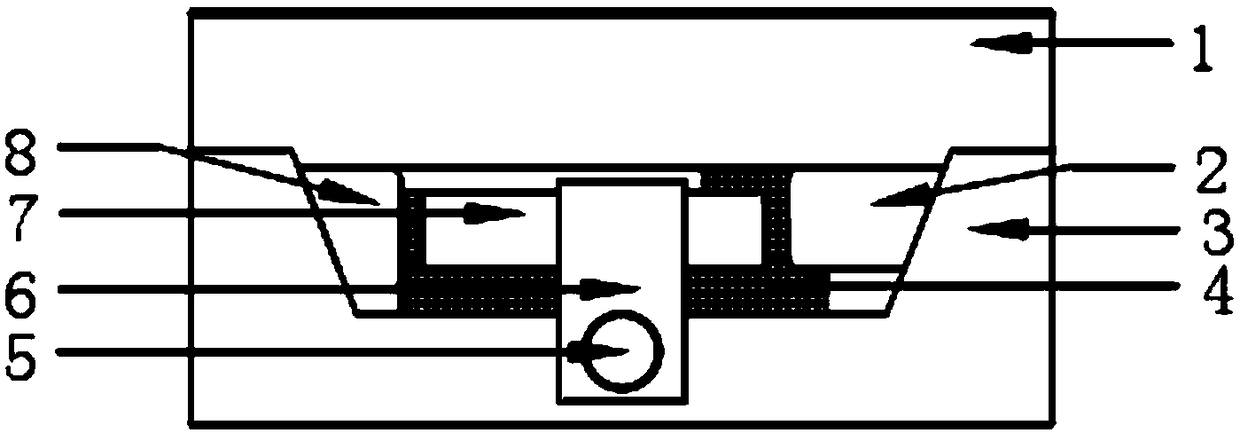

A technology for composite materials and molds, which is applied in the field of molds for the preparation of composite material reinforced structures, to achieve the effects of easy disassembly, convenient operation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

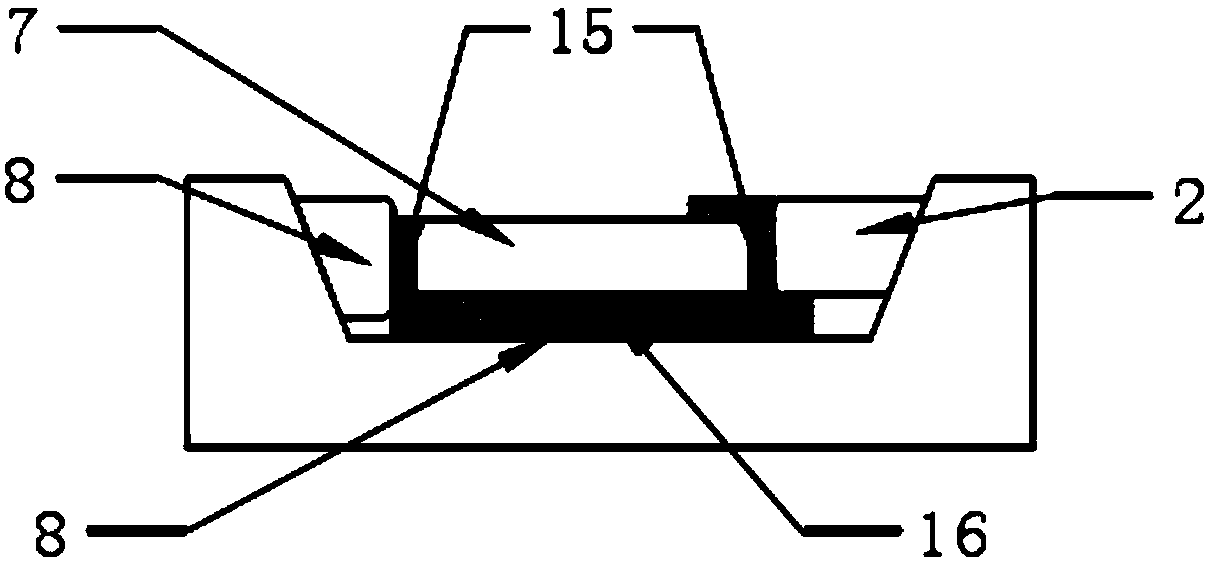

[0029] See attached figure 2 As shown, the above-mentioned mold is used to prepare a ceramic matrix composite reinforced structure. The steps of forming and the method of using the mold are as follows:

[0030] Step 1. Use 45 to process the forming mold. The structure of the formed part is a flat plate reinforced structure. The angle of the matching surface of the processing rib and the slider is 25-50°. times.

[0031] Step 2: Cut and lay the SiC fiber prepreg according to the size requirements of the molding component, then place the prepreg in the compression molding mold, and install the left and right sliders and the core mold of the molding mold. Confirm the installation position of each module, and after ensuring that the installation is correct, install the mandrel bar and male mold;

[0032] Step 3. Place the mold on the press, set the temperature rise rate of the press to 2°C / min, raise the temperature to 300°C, set the pressure to 10Mpa, and keep the pressure for...

Embodiment 2

[0036] Using the above mold to prepare another ceramic matrix composite material reinforced structure, the forming steps and the method of using the mold are as follows:

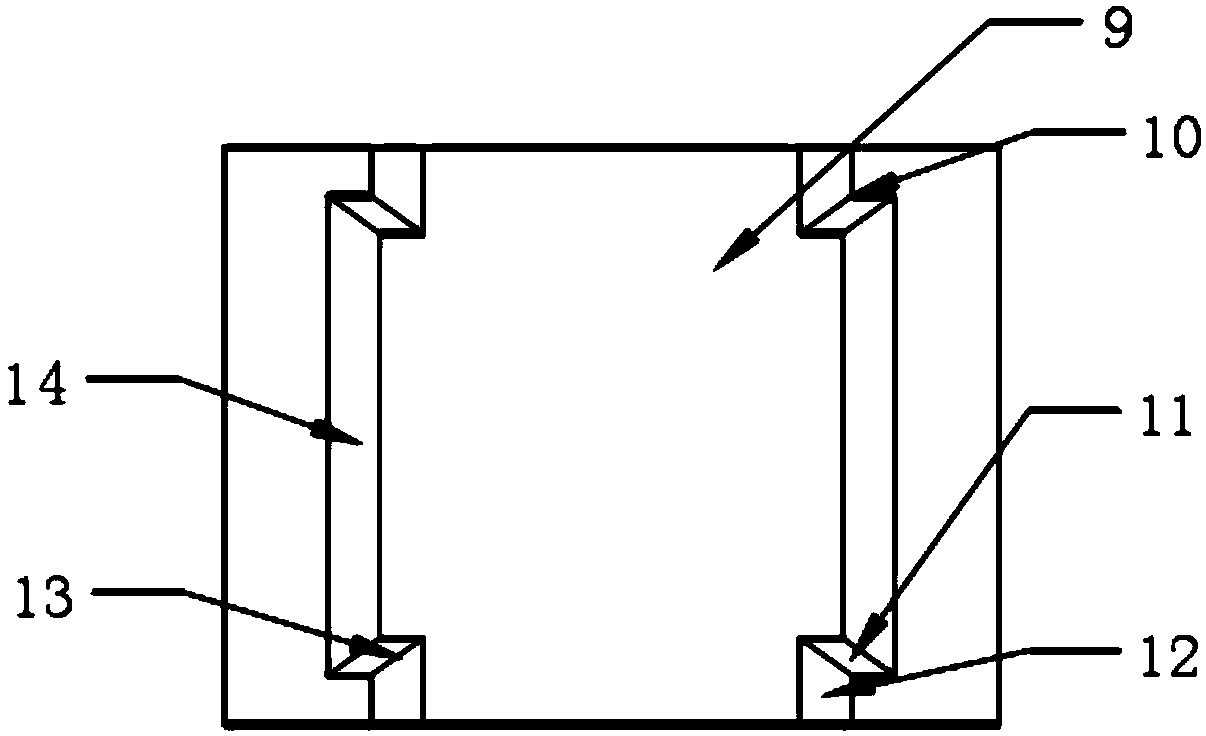

[0037] Step 1. Use 3Cr2Mo to process the forming mold. The structure of the formed part is a flat plate reinforced structure. The angle of the matching surface of the processed rib and the slider is 30°~50°. 2 times.

[0038] Step 2: Cut and lay the SiC fiber prepreg according to the size requirements of the molding component, then place the prepreg in the compression molding mold, and install the left and right sliders and the core mold of the molding mold. Confirm the installation position of each module, and after ensuring that the installation is correct, install the mandrel bar and male mold;

[0039] Step 3. Place the mold on the press, set the temperature rise rate of the press to 2°C / min, raise the temperature to 350°C, set the pressure to 8Mpa, and keep the pressure for 6h;

[0040] Step 4. After ...

Embodiment 3

[0043] Using the above-mentioned mold to prepare yet another ceramic matrix composite reinforced structure, the forming steps and the method of using the mold are as follows:

[0044] Step 1. Use 3Cr2Mo to process the forming mold. The slider, female mold and male mold forming surfaces are all processed into arc shapes, which are used to prepare the reinforced structure of arc parts. The angle of the processed rib and the mating surface of the slider is 30-45° , The matching length of the male mold and the female mold slideway is 5 times the thickness of the component.

[0045] Step 2: Cut and lay the SiC fiber prepreg according to the size requirements of the molding component, then place the prepreg in the compression molding mold, and install the left and right sliders and the core mold of the molding mold. Confirm the installation position of each module, and after ensuring that the installation is correct, install the mandrel bar and male mold;

[0046] Step 3. Place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com