Surface curing device and method suitable for thermal insulation material

A thermal insulation material and surface curing technology, which is applied to the surface coating liquid device, spray device, pretreatment surface, etc., can solve the problems of poor curing effect of thermal insulation materials, increased labor intensity of manual operation, and reduced quality of thermal insulation materials, etc. , to achieve uniform force, increase the speed of conveying, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

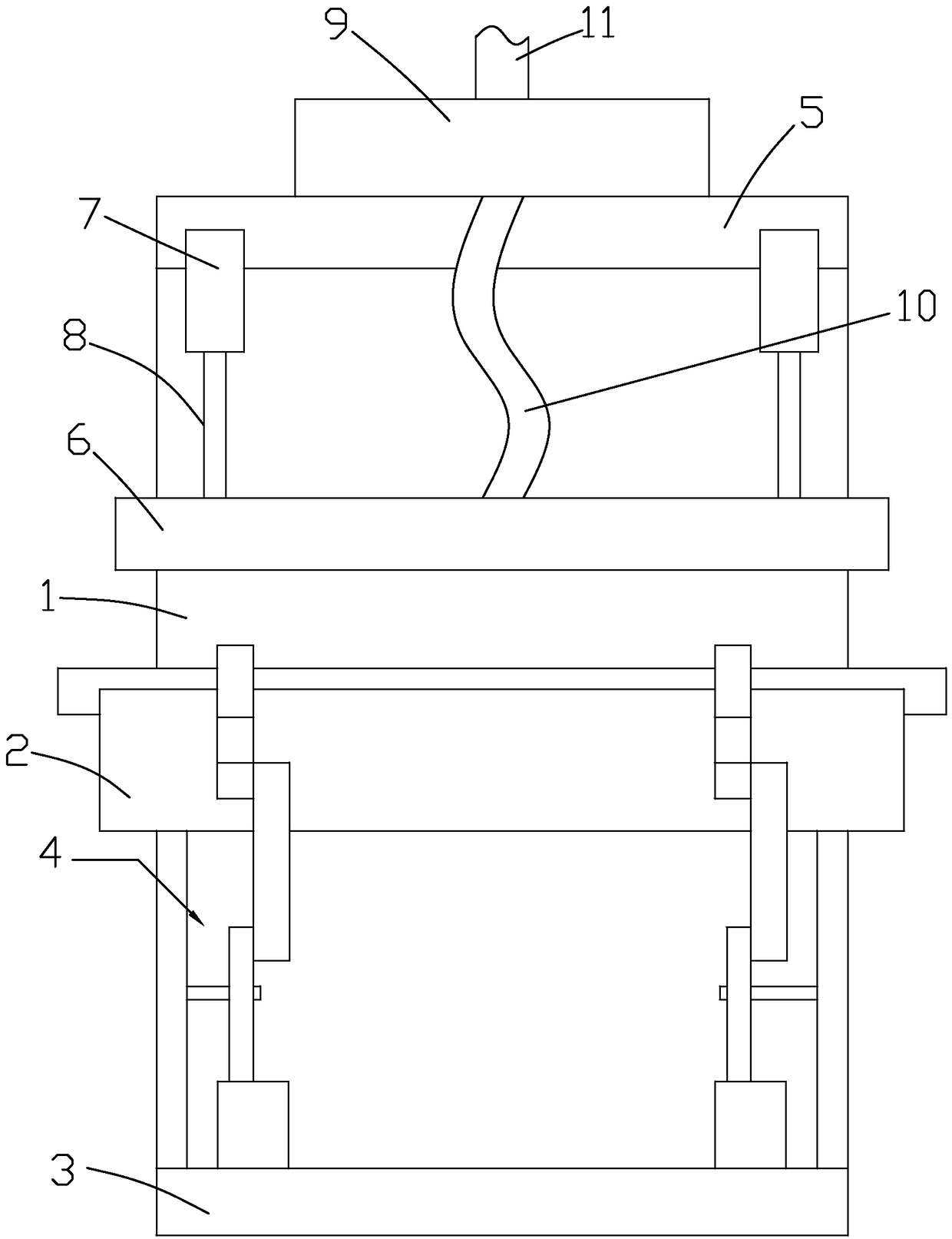

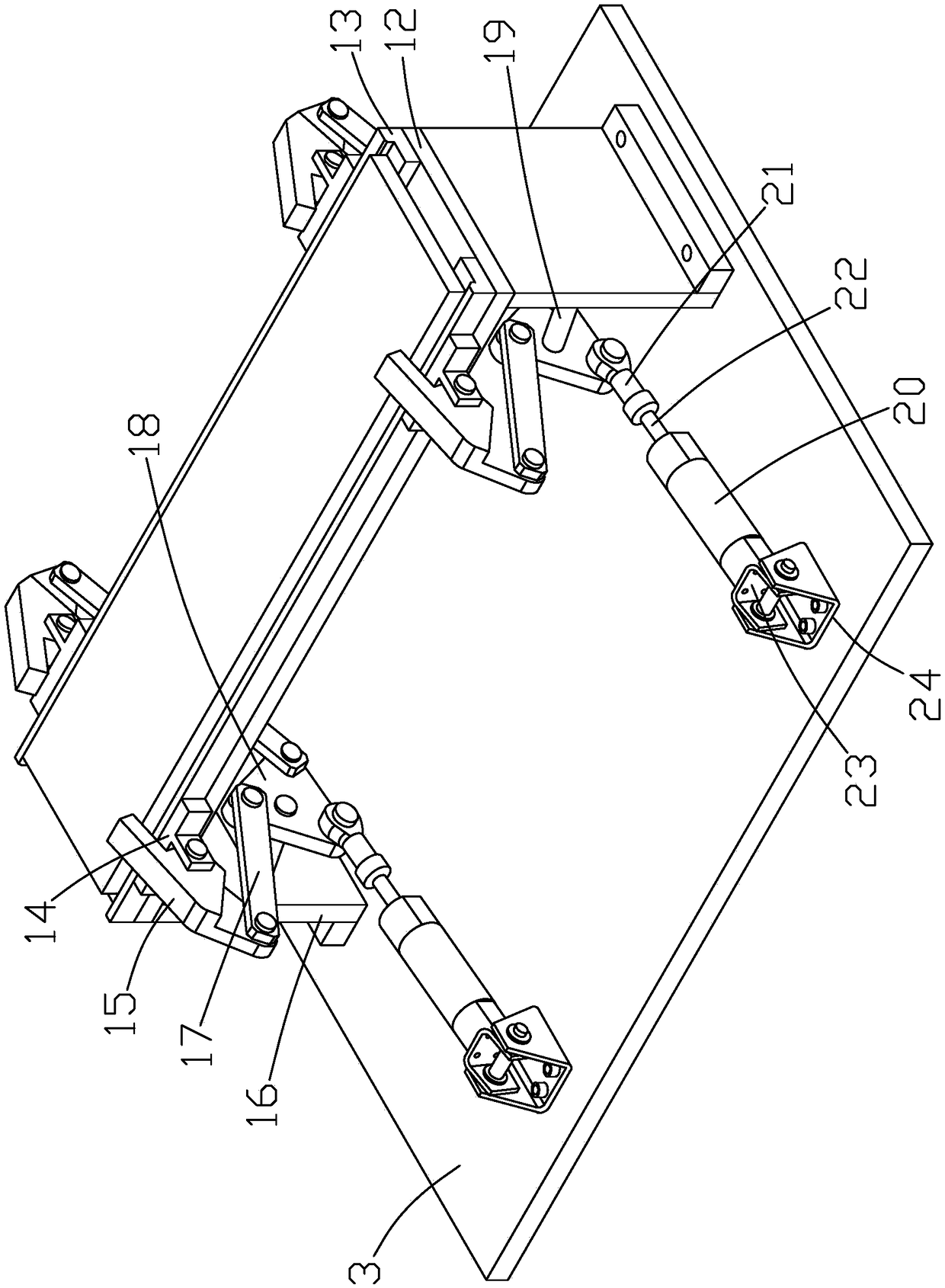

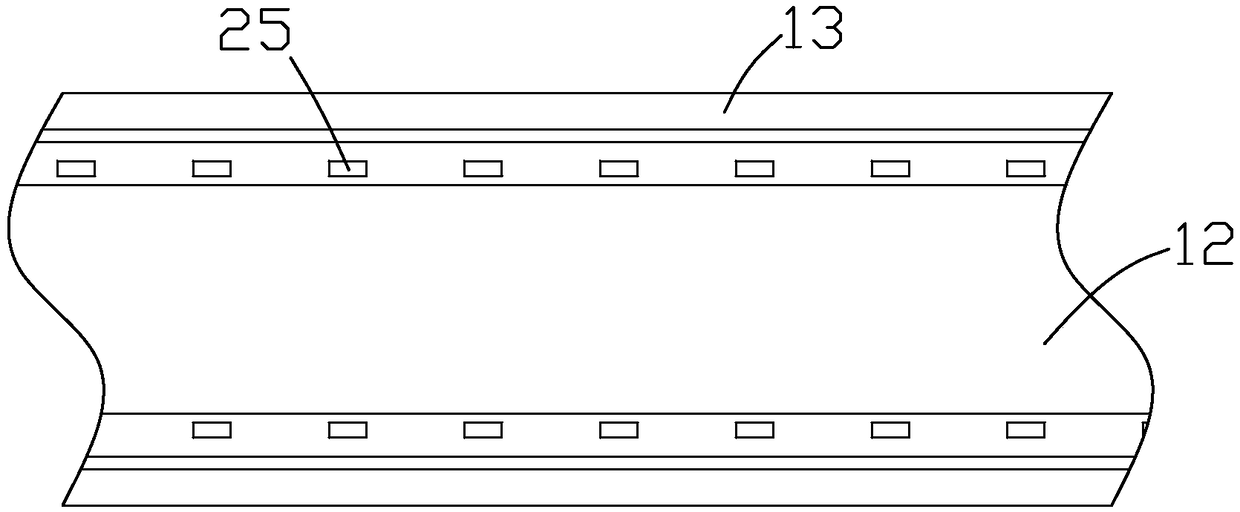

[0039] Such as Figure 1 to Figure 4 As shown, it is a surface curing device suitable for thermal insulation materials according to the present invention, which includes a body 1, a curing table 2 and a curing mechanism 6, the bottom of the body 1 is provided with a bottom plate 3, the curing table 2 is located in the middle of the body 1, and the curing table 2 Including a positioning plate 12 and a guide rail 13, the guide rails 13 are symmetrically arranged on both sides of the top surface of the positioning plate 12, and rollers 25 are evenly arranged on the guide rail 13, the positioning plate 12 can play a role of supporting positioning, and the guide rail 13 can limit the thermal insulation material. position, so that the thermal insulation material keeps moving in a straight line, and the roller 25 can reduce the friction between the thermal insulation material and the guide rail 13, so as to facilitate the movement of the thermal insulation material.

[0040] The curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com