Preparation method of carboxylated graphene oxide nanofiltration membrane with controllable flux

A carboxylation and nanofiltration membrane technology, applied in the field of composite membrane materials, can solve the problems such as the flux is not greatly improved, the preparation method is complicated, and the effect of low production cost, simple preparation process and good separation performance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

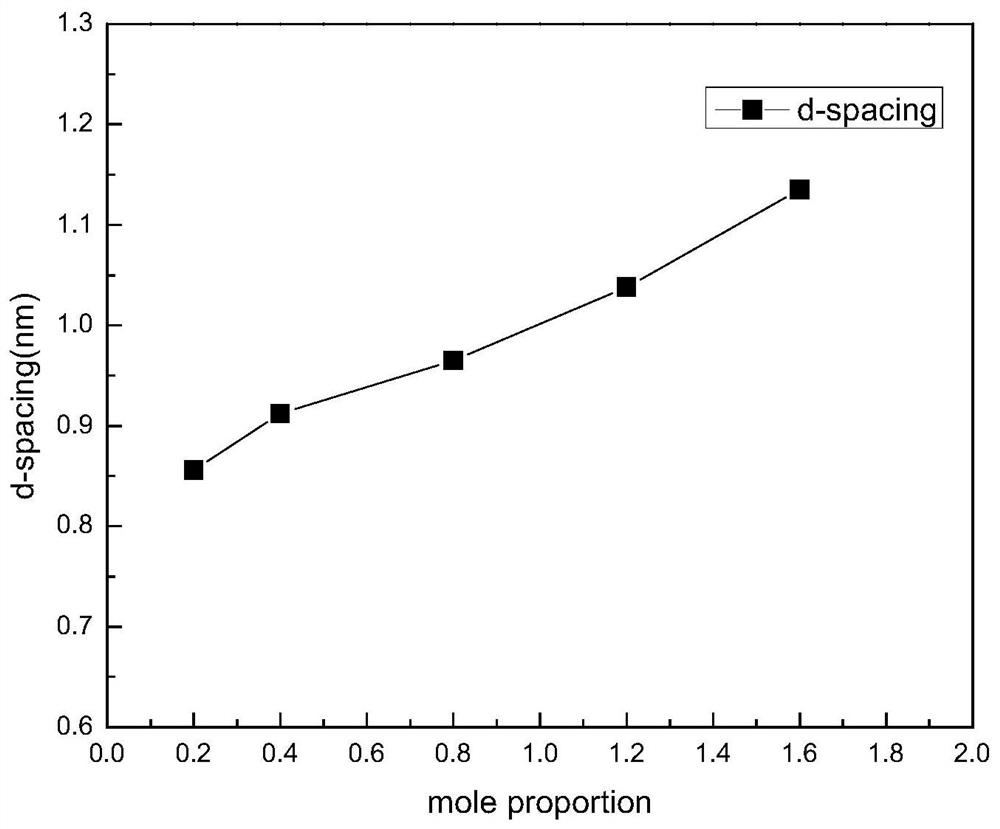

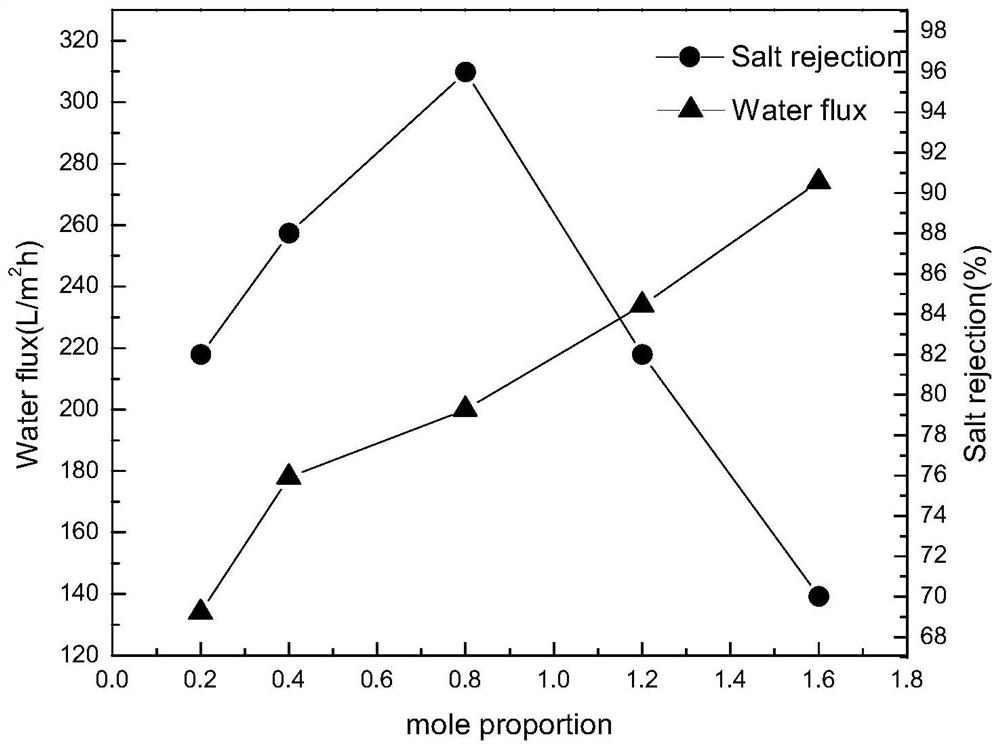

[0023] First, 15mL of hydrobromic acid (HBr) was added to 90mL of graphene oxide (GO) solution, stirred continuously for 12h, then 8g of oxalic acid was added to the above mixture, stirred continuously for 4h, and dialyzed for 1 week to obtain CFGO solution (5mg / mL), take 0.5mL of the prepared CFGO solution in a 50mL volumetric flask, add 1mL of 1mol / L MXDA aqueous solution, dilute to 50mL with deionized water, the molar concentration of MXDA in the mixed solution is 0.02mol / L, vacuum pump Filter the mixture of CFGO and MXDA on the surface of the PES base membrane. After rinsing, soak in 20ml 0.1mol / L TMC / n-hexane solution to obtain a composite membrane. The molar concentration ratio of MXDA aqueous solution to TMC / n-hexane solution is 0.2 , the interlayer distance (d-spacing) of the obtained composite membrane is 0.856nm, and the pure water flux (Water Flux) is 134L / m under the pressure of 0.5Mpa 2 h, for calcium chloride (CaCl 2 ) The rejection rate (Salt Rejection) is 82%...

Embodiment 2

[0025] First, 15mL of hydrobromic acid (HBr) was added to 90mL of graphene oxide (GO) solution, stirred continuously for 12h, then 8g of oxalic acid was added to the above mixture, stirred continuously for 4h, and dialyzed for 1 week to obtain CFGO solution (5mg / mL), take 0.5mL of the prepared CFGO solution in a 50mL volumetric flask, add 2mL of 1mol / L MXDA aqueous solution, dilute to 50mL with deionized water, the molar concentration of MXDA in the mixed solution is 0.04mol / L, and vacuum Filter the mixture of CFGO and MXDA on the surface of the PES base membrane. After rinsing, soak in 20ml 0.1mol / L TMC / n-hexane solution to obtain a composite membrane. The molar concentration ratio of MXDA aqueous solution to TMC / n-hexane solution is 0.4 , the interlayer distance (d-spacing) of the obtained composite membrane is 0.912nm, and the pure water flux is 178L / m under the pressure of 0.5MPa 2 h, for CaCl 2 The rejection rate is 88%.

Embodiment 3

[0027] First, 15mL of hydrobromic acid (HBr) was added to 90mL of graphene oxide (GO) solution, stirred continuously for 12h, then 8g of oxalic acid was added to the above mixture, stirred continuously for 4h, and dialyzed for 1 week to obtain CFGO solution (5mg / mL), take 0.5mL of the prepared CFGO solution in a 50mL volumetric flask, add 4mL of 1mol / L MXDA aqueous solution, use deionized water to set the volume to 50mL, the molar concentration of MXDA in the mixed solution is 0.08mol / L, vacuum pump Filter the mixture of CFGO and MXDA on the surface of the PES base membrane. After rinsing, soak in 20ml 0.1mol / L TMC / n-hexane solution to obtain a composite membrane. The molar concentration ratio of MXDA aqueous solution to TMC / n-hexane solution is 0.8 , the interlayer distance (d-spacing) of the obtained composite membrane is 0.965nm, and the pure water flux is 200L / m under the pressure of 0.5Mpa 2 h, for CaCl 2 The rejection rate is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com