Method for synchronously supplying short cigarettes in manufacture of heating incombustible cigarettes

A heat-not-burn, cigarette technology, applied in the manufacture of cigarettes, tobacco, applications, etc., can solve the problems of short and unstable, and achieve the effects of low cost, stable operation and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The purpose of this new method is to achieve:

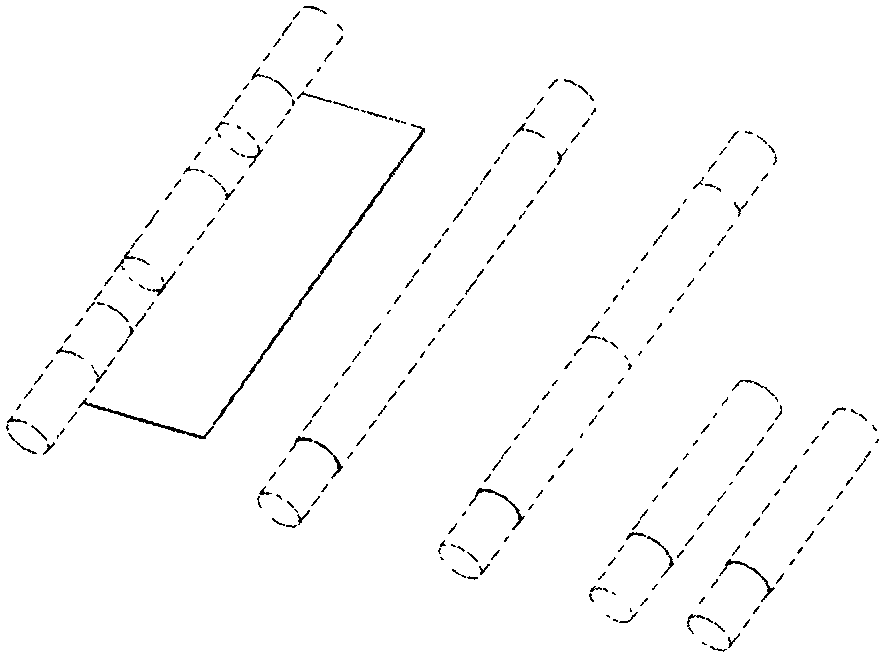

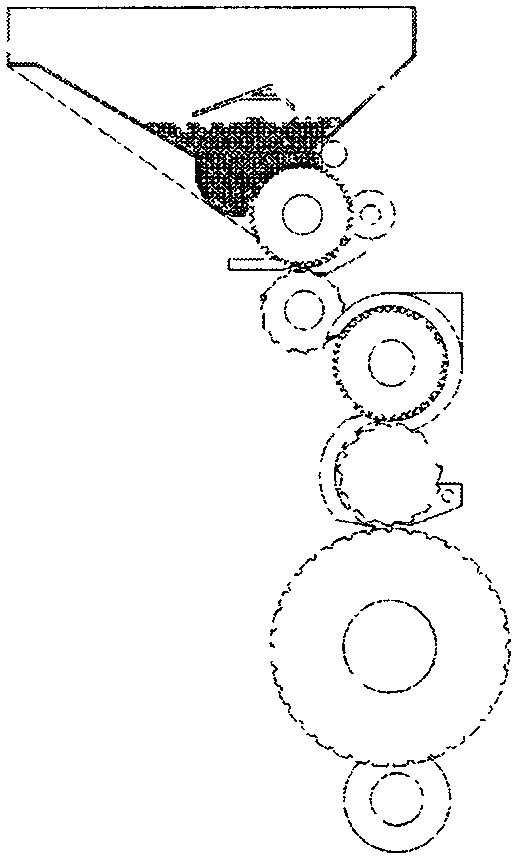

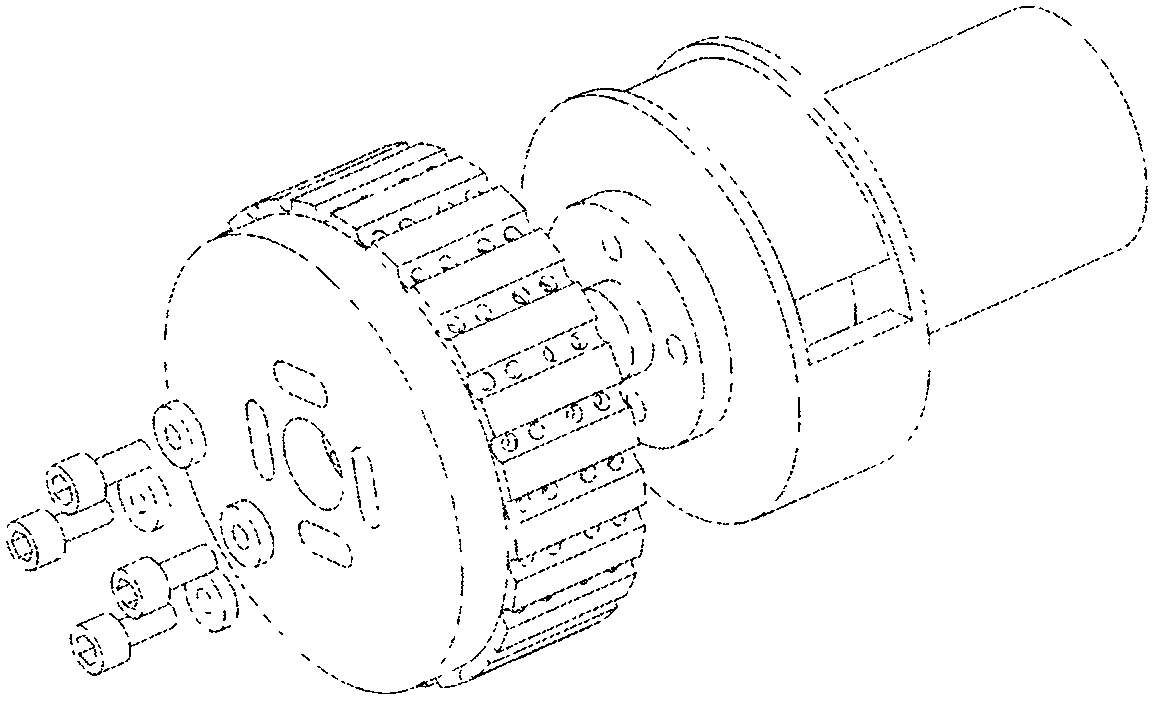

[0012] The cigarette making machine of the original rolling and splicing unit is produced by synchronously supplying cigarettes that are 2 times as long as the length of cigarettes required by the splicing and splicing machine, and synchronously supplying cigarettes that are 4 times as long as the length of short cigarettes required by the splicing and splicing machine. For the production of the tipping machine, the speed of the cigarette rolling machine is reduced by half, and the production is more stable. The device of this new method is made up of 4 drums (such as Figure 4 shown), the structure and working principle of these rotating drums are basically the same as the original tipping machine drums (such as image 3 shown). There are evenly distributed semicircular smoke receiving grooves on the drum, and the bottom of the smoke receiving grooves has negative pressure suction holes to absorb cigarettes. There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com