Kombucha fermentation whole soybean milk and production method thereof

A production method and technology of kombucha, which are applied in the field of deep processing of soy products, can solve the problems of loss of soybean nutrition and health care substances, single variety of fermented soy products, small choice for consumers, etc., and achieve low prices, reduced enterprise investment, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

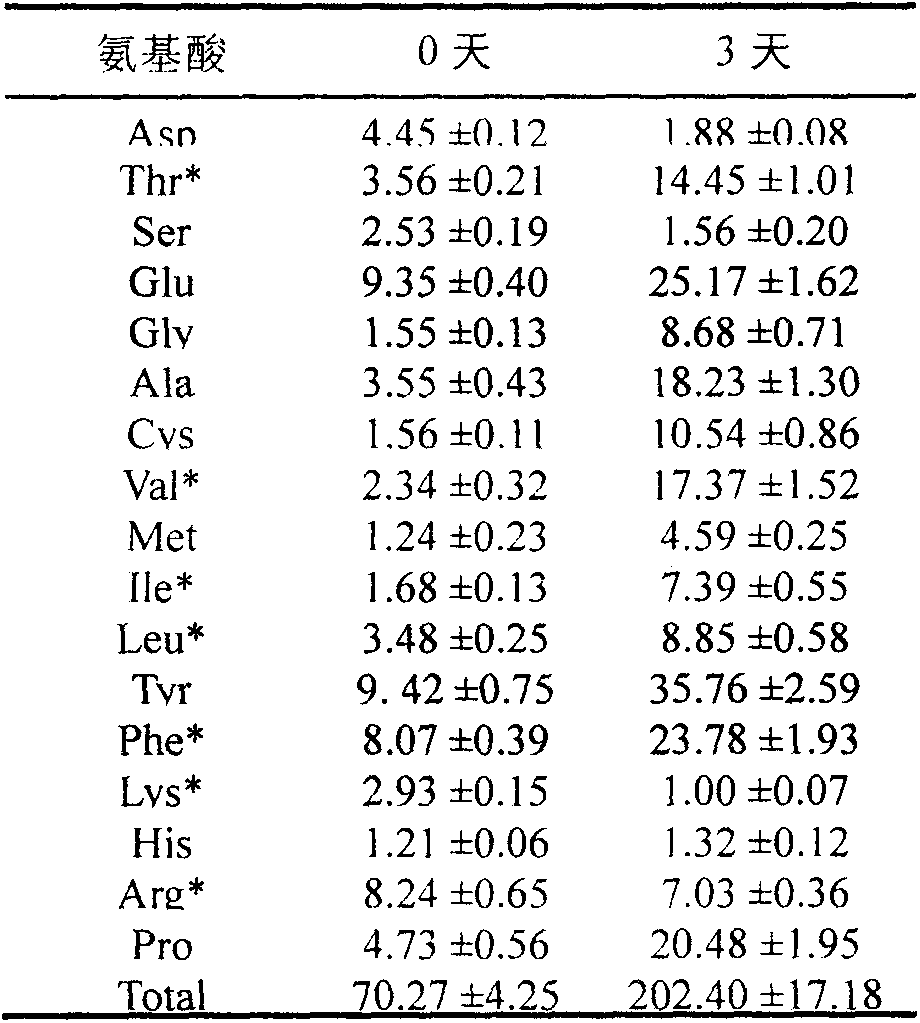

Image

Examples

Embodiment 1

[0031] (1) Soak the soybeans in water for 8 hours according to the ratio of soybean water mass ratio of 1:6 after cleaning the soybeans;

[0032] (2) First crush the soaked soybeans and water with a coarse pulverizer, then add them to a colloid mill and pulverize them for 3 times, and then use a two-stage high-pressure homogenization method to homogenize twice at a temperature of 65°C. The mass pressure is 25MPa, and the homogeneous pressure of the second stage is 4.0MPa;

[0033] (3) Whole soy milk is sterilized at 85°C for 25 minutes and cooled to room temperature to obtain sterilized whole soy milk;

[0034] (4) Green tea, sucrose and water are mixed and stirred according to the mass ratio of 0.3:8:100. After the sucrose is fully dissolved, the mixture is heated at 95° C. for 10 minutes, cooled, and the tea leaves are filtered to obtain sugar tea water.

[0035] (5) adding commercially available kombucha into the prepared sugar tea water and fermenting for 5 days to obtain...

Embodiment 2

[0046] (1) Soak the soybeans in water for 24 hours according to the ratio of soybean water mass ratio of 1:8 after cleaning the soybeans;

[0047] (2) Grind the soaked soybeans and water together with a coarse pulverizer first, then add them to a colloid mill and pulverize them twice, and then use a two-stage high-pressure homogenization method to homogenize three times at a temperature of 60°C. The mass pressure is 25MPa, and the homogeneous pressure of the second stage is 5.0MPa;

[0048] (3) Whole soy milk is sterilized at 90°C for 20 minutes and cooled to room temperature to obtain sterilized whole soy milk;

[0049] (4) Black tea, sucrose and water are mixed and stirred according to the mass ratio of 0.8:8:100. After the sucrose is fully dissolved, the mixture is heated at 95° C. for 8 minutes, cooled, and the tea leaves are filtered to obtain sugar tea water.

[0050] (5) adding the commercially available kombucha into the prepared sugar tea water and fermenting for 15 ...

Embodiment 3

[0054] (1) Soak the soybeans in water for 12 hours according to the ratio of soybean water mass ratio of 1:8 after cleaning the soybeans;

[0055] (2) Grind the soaked soybeans and water together with a coarse pulverizer first, then add them to a colloid mill and pulverize them twice, and then use a two-stage high-pressure homogenization method to homogenize twice at a temperature of 60°C. The mass pressure is 25MPa, and the homogeneous pressure of the second stage is 5.0MPa;

[0056] (3) Whole soy milk is sterilized at 85°C for 20 minutes and cooled to room temperature to obtain sterilized whole soy milk;

[0057] (4) Black tea, sucrose and water are mixed and stirred according to the mass ratio of 0.5:8:100, the sucrose is fully dissolved, heated at 98° C. for 5 minutes, cooled, and the tea leaves are filtered to obtain sugar tea.

[0058] (5) Gluconacetobacter sp. (Gluconacetobacter sp., purchased from the China Industrial Microorganism Culture Collection Management Center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com