Pd/MGN composite material with high oxidization reduction electrocatalytic activity as well as preparation method and application thereof

A composite material and electrocatalysis technology, applied in nanotechnology, circuits, electrical components, etc. for materials and surface science, can solve the problems of large size of Pd nanoparticles, interference with catalytic ORR activity, and low mass transfer rate of the carrier. Achieve the effects of simple preparation, high conductivity, and improved catalytic activity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

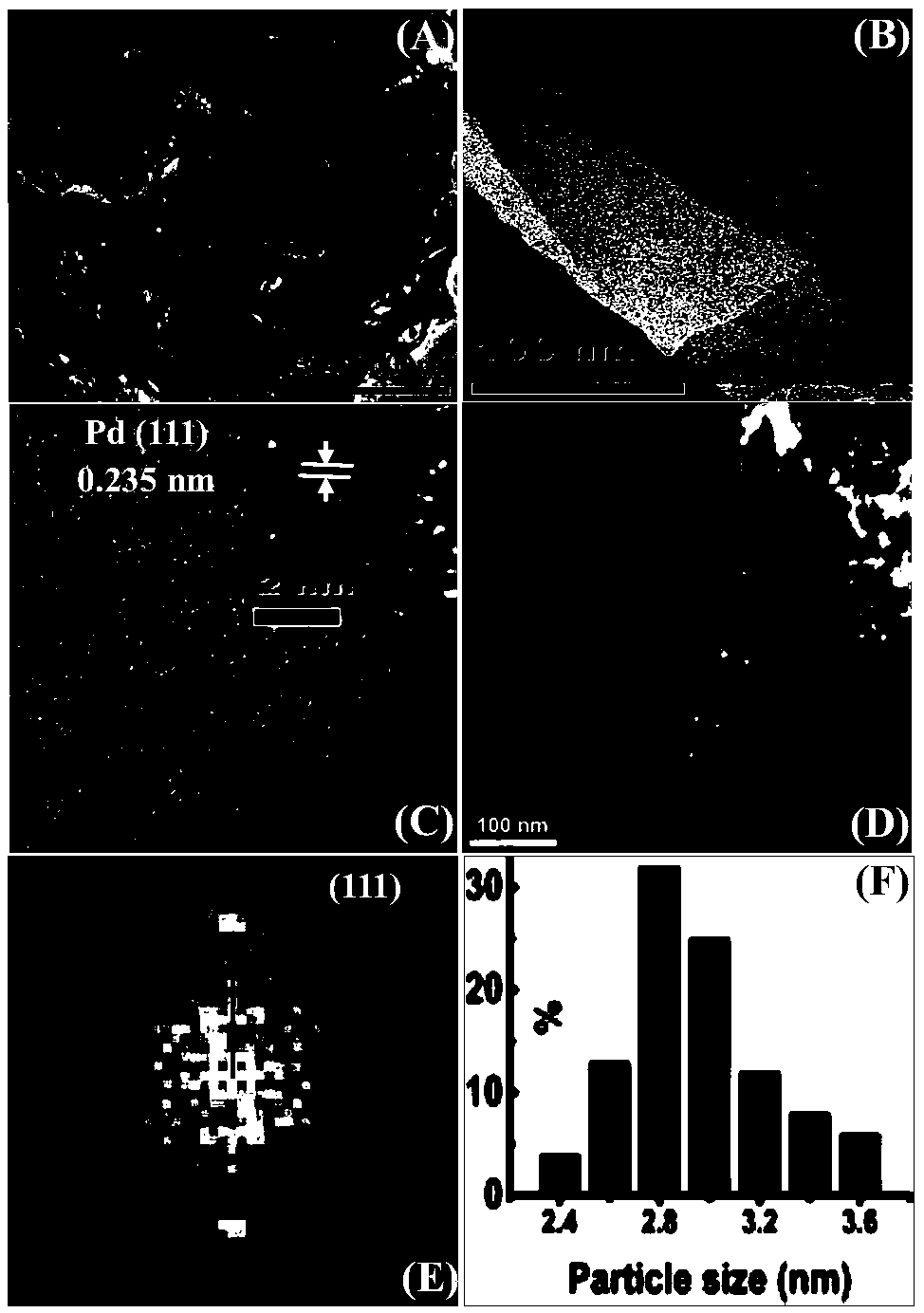

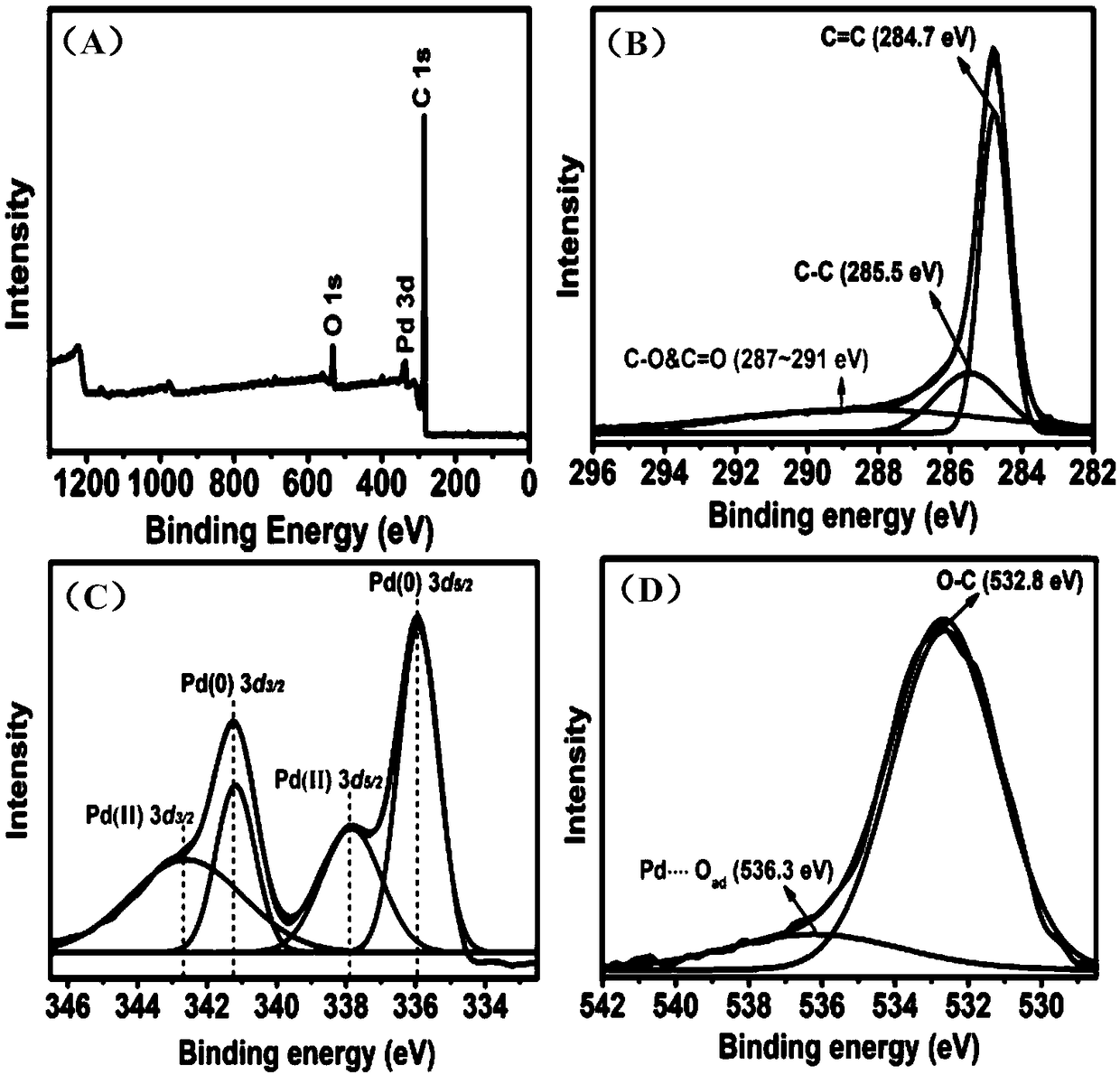

[0037] (1) Add 2g of MCM-22 to a mixed solution containing 1.45g of sucrose, 100μl of concentrated sulfuric acid and 6ml of water, stir evenly, and after standing for 6h, pre-carbonize at 160°C for 18h, then add 0.87g of sucrose, 60μl A mixed solution of concentrated sulfuric acid and 6ml of water was stirred evenly, left to stand for 6 hours, and then pre-carbonized at 160°C for 18 hours to obtain a solid powder.

[0038] (2) the solid powder in step (1) is put into the tube furnace, and the Ar 2 After calcining at 800°C for 2h, take it out to obtain MCM-22 / mesoporous graphene network composite material, put it into 2.5L NaOH (4mol / L) solution, stir at 70°C for 6h, centrifuge, wash with water until neutral, Freeze-drying can get mesoporous graphene network (MGN) powder.

[0039] (3) Add 0.3 mL K to 2.5 mL mesoporous graphene network (MGN) aqueous solution (20 mg / mL) dispersed uniform 2 PdCl 4 aqueous solution (0.15mol / L), after ultrasonication for 30min, add 0.5mL NaOH (1m...

Embodiment 2

[0047] (1) Add 1.3g of MCM-22 to the mixed solution containing 0.9g of sucrose, 60μl of concentrated sulfuric acid and 3ml of water, stir evenly, after standing for 6h, pre-carbonize at 180°C for 12h, then add 0.5g of sucrose, A mixed solution of 30 μl of concentrated sulfuric acid and 3ml of water was stirred evenly, left to stand for 6 hours, and then pre-carbonized at 100°C for 18 hours to obtain a solid powder.

[0048] (2) the solid powder in step (1) is put into the tube furnace, and the Ar 2 After calcining at 800°C for 2h, take it out to obtain MCM-22 / mesoporous graphene network composite material, put it into 2.5L NaOH (4mol / L) solution, stir at 60°C for 2h, centrifuge, wash with water until neutral, Freeze-drying can get mesoporous graphene network (MGN) powder.

[0049] (3) Add 0.06mL K 2 PdCl 4 aqueous solution (0.15mol / L), after ultrasonication for 30min, add 0.1mL NaOH (2mol / L) and NaBH 4 (1mol / L) mixed aqueous solution, stirred at 50° for 1h, centrifuged at ...

Embodiment 3

[0051] (1) Add 1g MCM-22 to the mixed solution containing 0.8g sucrose, 50μl concentrated sulfuric acid and 3ml water, stir evenly, after standing for 5h, pre-carbonize at 160℃ for 18h, then add 0.4g sucrose, 30μl A mixed solution of concentrated sulfuric acid and 3ml of water was stirred evenly, allowed to stand for 5 hours, and then pre-carbonized at 160°C for 18 hours to obtain a solid powder.

[0052] (2) the solid powder in step (1) is put into the tube furnace, and the Ar 2 After calcining at 1100°C for 2h, take it out to obtain MCM-22 / mesoporous graphene network composite material, put it into 1.5L NaOH (4mol / L) solution, stir at 60°C for 6h, centrifuge, wash with water until neutral, Freeze-drying can get mesoporous graphene network (MGN) powder.

[0053] (3) Then add 0.6mLK to 5mL mesoporous graphene network (MGN) aqueous solution (20mg / mL) dispersed uniformly 2 PdCl 4 aqueous solution (0.15mol / L), after ultrasonication for 30min, add 0.1mL NaOH (1mol / L) and NaBH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com