Embedded buffering closing-assisted locking mechanism for large-sized armrest

A locking mechanism and built-in technology, applied in the direction of handrails, etc., can solve the problems of large layout space, limited buffer force, and affecting appearance, and achieve the effect of wide application, small space occupation, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

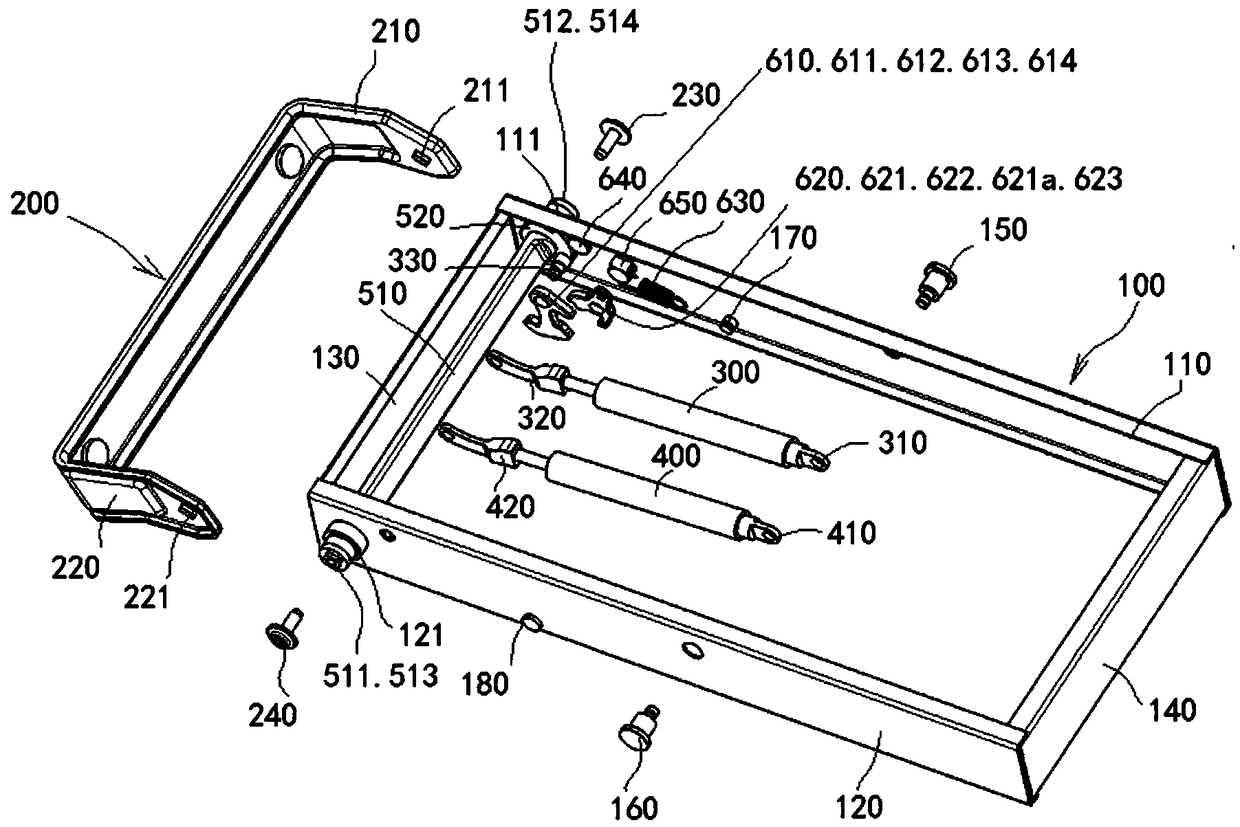

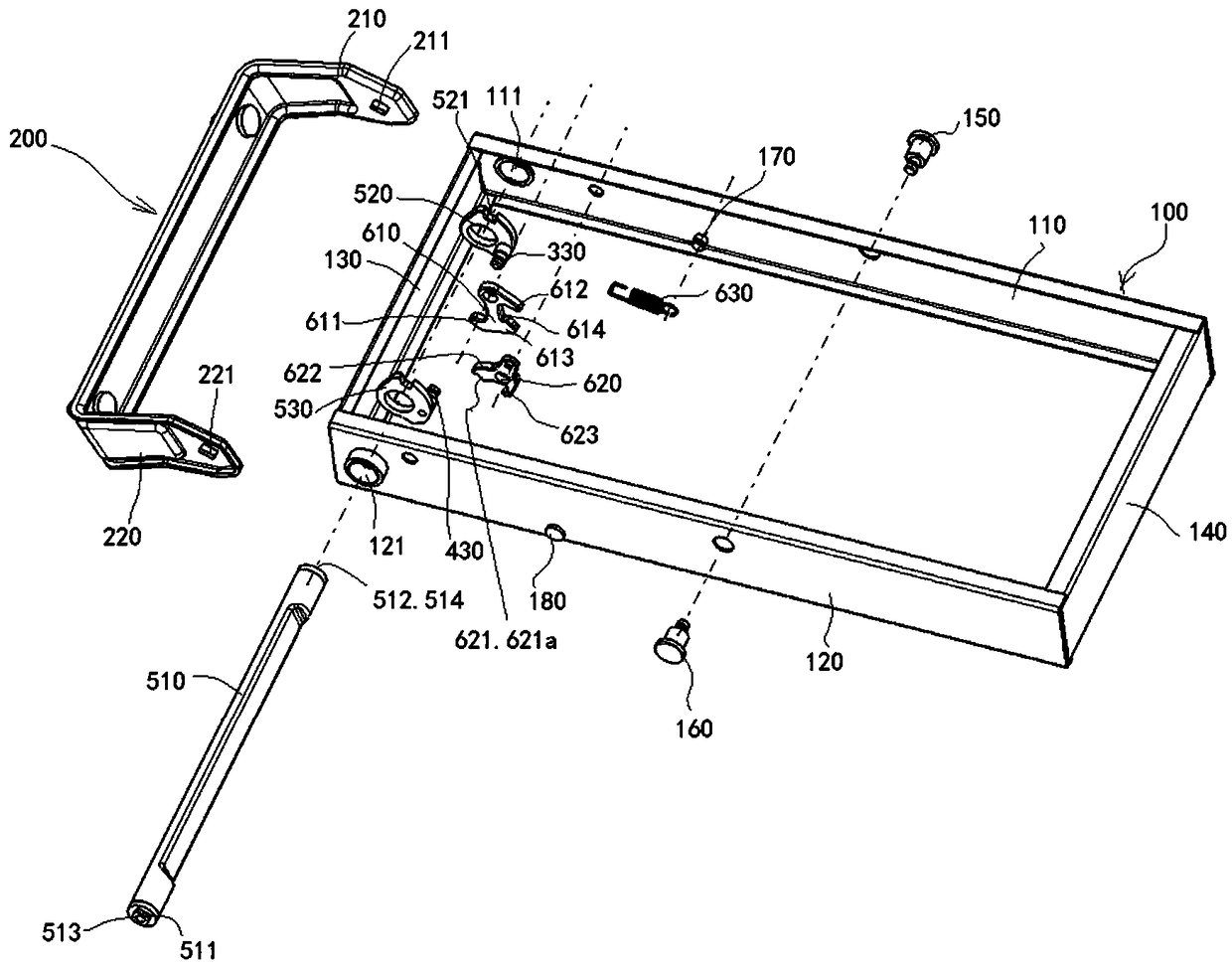

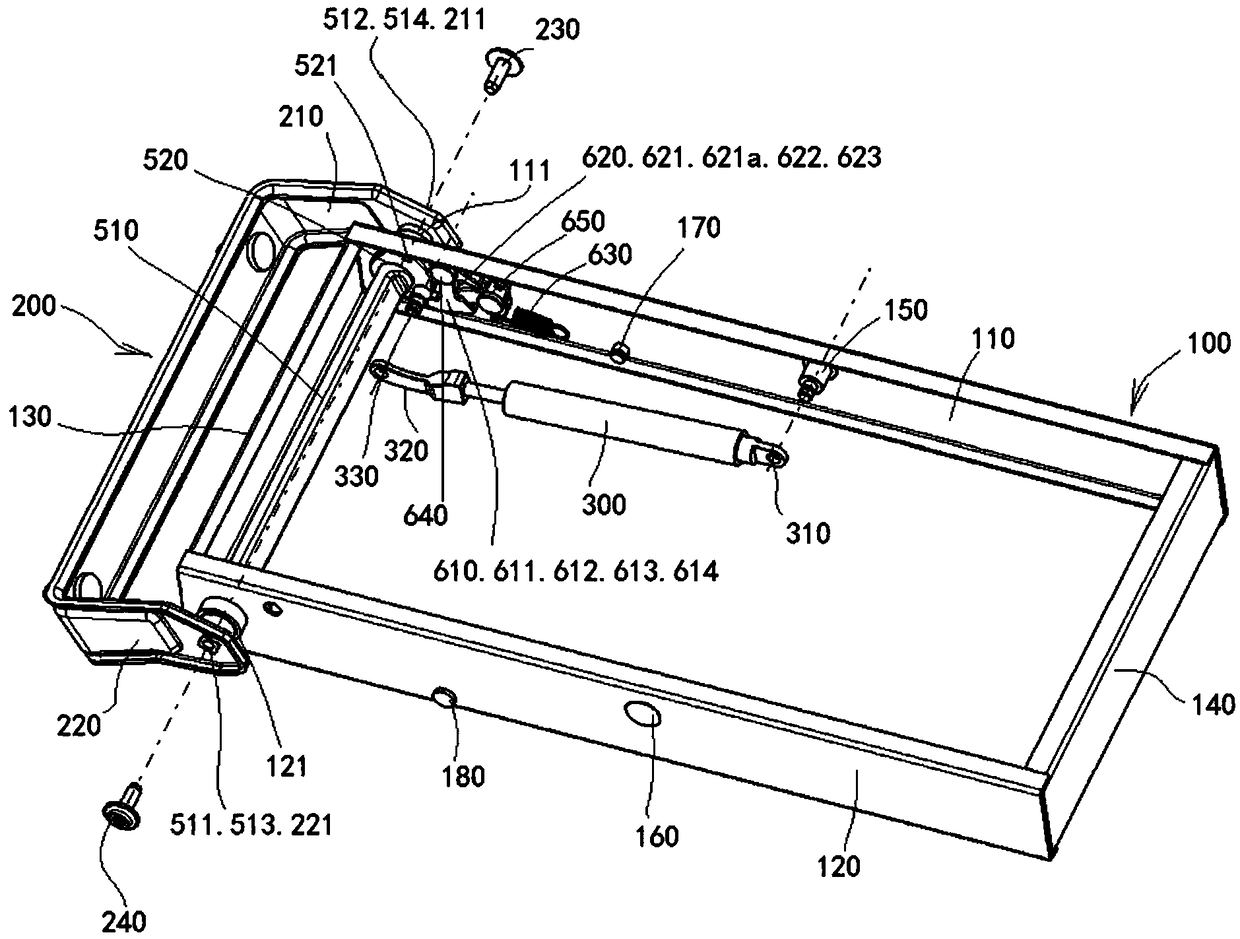

[0029] see Figure 1 to Figure 5 , a built-in large armrest buffer assist locking mechanism shown in the figure, including the armrest, the armrest includes the armrest skeleton assembly 100 and the hinge assembly 200, which also includes the torque hinge support assembly, the driving mechanism 300, the locking And unlocking assembly and damping mechanism 400.

[0030] The armrest frame assembly 100 is made up of two parallel side walls 110, 120 and two parallel end walls 130, 140, wherein the two ends of the end wall 130 are welded to one end of the two side walls 110, 120 respectively, and the two ends of the end wall 140 The two ends are welded to the other ends of the two side walls 110 and 120 respectively. A light hole 111 , 121 is respectively defined on the two side walls 110 , 120 near the end wall 130 . A fixed hinge support 150 , 160 is respectively anchored in the middle of the two sidewalls 110 , 120 , and a return spring connection point 170 , 180 is respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com