High-thrust double three-phase permanent magnet linear synchronous motor for non-rope elevator hoisting system

A dual three-phase permanent magnet, linear synchronous technology, used in propulsion systems, electric components, elevators in buildings, etc., can solve problems such as limiting the application of multi-phase motors, and achieve good fault tolerance, low thrust loss, and processing. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

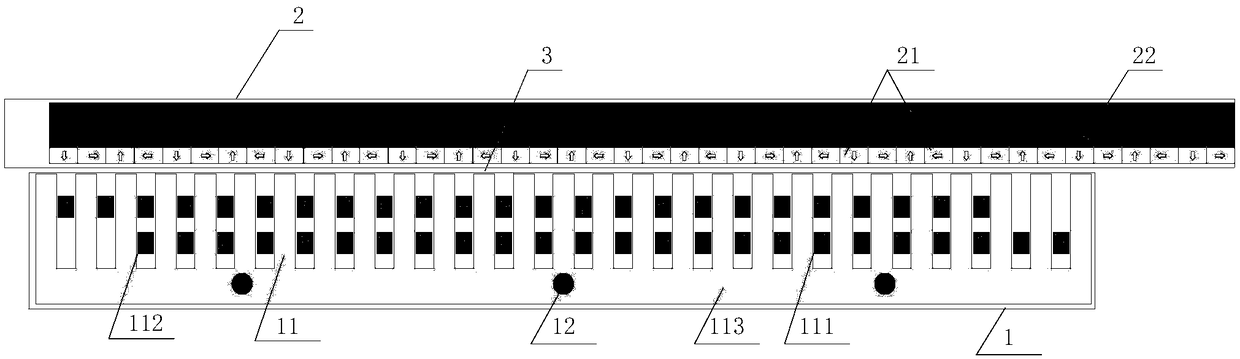

[0030] like figure 1 As shown, the high-thrust dual-three-phase permanent magnet linear synchronous motor used in the hoisting system of a cordless elevator in this embodiment includes a primary 1 and a secondary 2, and the primary 1 includes an armature 11 and mounting bolts 12, wherein the armature 11 includes two sets The armature windings 111-112 and the armature core 113, the secondary 2 includes the magnetic pole 21 and the back iron 22, the magnetic pole 21 is composed of permanent magnets with two magnetization methods, one is perpendicular to the direction of motion of the motor, and the other is Horizontal to the moving direction of the motor, the armature 11 is fixed on the wall of the elevator shaft, the back iron 22 is rigidly connected to the elevator car, and the primary 1 and secondary 2 maintain a certain air gap 3.

[0031] In this embodiment, two sets of the same windings 112 and 113 are used. The two sets of windings are embedded in the armature slots in th...

Embodiment 2

[0036] figure 2 A deformation structure of the motor of the present invention is shown. The difference from Embodiment 1 is that the relative positions of the permanent magnet and the armature are different. In this implementation structure, the central axis of the permanent magnet and the axis of the first set of winding A align.

Embodiment 3

[0038] like image 3 As shown, the characteristic of this embodiment is that the two sets of windings 112 and 113 placed in the armature slots have an electrical angle difference of 15°, and the electromotive force of the slots is shown in Figure 6(b).

[0039] The working principle of the high-thrust double-three-phase permanent magnet linear synchronous motor used in the hoisting system of the cordless elevator in this embodiment is the same as that of the first embodiment. With the change of the secondary position, the flux linkage in the two sets of armature windings is positive and negative alternately. , but there is a 15° electrical angle difference between each other, which is basically sinusoidal and bipolar flux linkage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com