Microwave converter

A converter and microwave technology, applied in the field of microwave converters, can solve the problems of insufficient number of microwaves, failure to remove algae and sterilization, and ultraviolet wavelengths not within the standard range, and achieve reasonable design, simple structure, and good algae removal and sterilization. The effect of disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

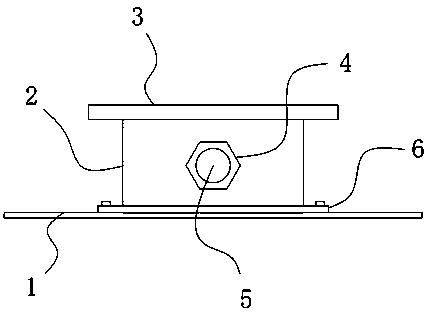

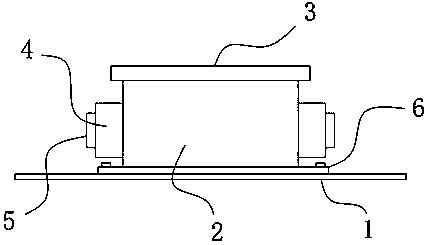

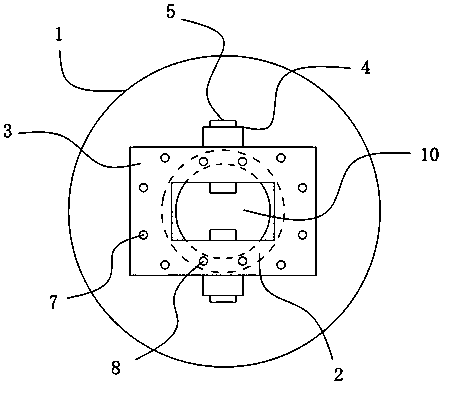

[0023] see Figure 1-4 , a microwave converter, including a mounting plate 1, a waveguide 2 is fixedly installed on the mounting plate 1, and two symmetrically arranged adjusting bolts 5 are threaded on the side walls of the waveguide 2, and the adjusting bolts 5 are The end away from the waveguide 2 is sleeved with a nut 4, the upper end of the waveguide 2 is fixedly installed with a connecting plate 3, the upper end of the waveguide 2 is provided with several threaded holes, and the connecting plate 3 is provided with several mounting holes 7 and connected with The threaded hole is vertically corresponding to the connecting hole 8; the connecting plate 3 is provided with a microwave inlet hole 10 vertically corresponding to the inside of the waveguide 2, and the bottom of the mounting plate 1 is provided with a microwave outlet hole vertically corresponding to the inside of the waveguide 2 9.

[0024] The usage method and working principle of this embodiment:

[0025] When...

Embodiment 2

[0029] On the basis of Embodiment 1, in addition, the microwave exit hole 9 is a rectangular hole structure, and the lengths of its long side and short side are 87mm and 43mm respectively; the microwave exit hole 9 is a circular hole structure, and its diameter is 74mm. The connecting plate 3 is a rectangular plate structure, the length and width of the connecting plate 3 are 138mm and 95mm respectively, the mounting plate 1 is a circular plate structure, the diameter of the mounting plate 1 is 231mm, and the diameter of the adjusting bolt 5 is 9.7mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com