Remote data acquisition and analysis system for numerically-controlled machine tool

A technology of CNC machine tools and remote data, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of loss of collected data, the inability of servers to adapt to workshop electromagnetic interference, system downtime, etc., to improve automation and intelligence , improve portability, and reduce hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present disclosure is described in detail below in conjunction with accompanying drawing:

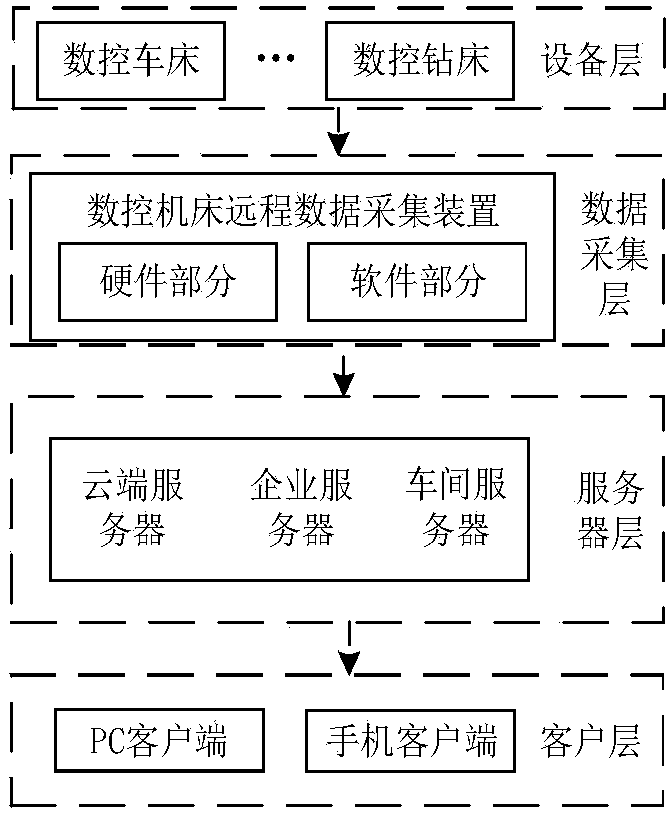

[0043] refer to figure 1 , the remote data acquisition and analysis system for CNC machine tools mainly includes four parts: equipment layer, data acquisition layer, server layer and client layer.

[0044] 1. Device layer

[0045] The equipment layer includes: CNC lathe, CNC milling machine, machining center, CNC drilling machine, CNC grinding machine, CNC boring and milling machine, CNC heavy-duty machine tool, CNC EDM machine tool, CNC wire cutting machine tool, CNC gear processing machine tool, CNC punching machine, CNC Various types of CNC machine tools such as hydraulic presses. CNC machine tools are generally controlled by CNC systems, including: FANUC CNC system (FANUC), Siemens CNC system (SIMENS), Huazhong CNC system, Guangzhou CNC system, HEIDENHAIN CNC system (HEIDENHAIN), Hans CNC system (HASS) ), Shenyang machine tool i5 system, Japan Mazak (MAZAK) CNC system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com