Method for adjusting self-collimation of interference optical path in holographic grating lithography system

A technology of holographic grating and lithography system is applied in the field of adjustment of the self-collimation optical path of the interference optical path, which can solve the problems of poor parallelism of the exposure beam and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

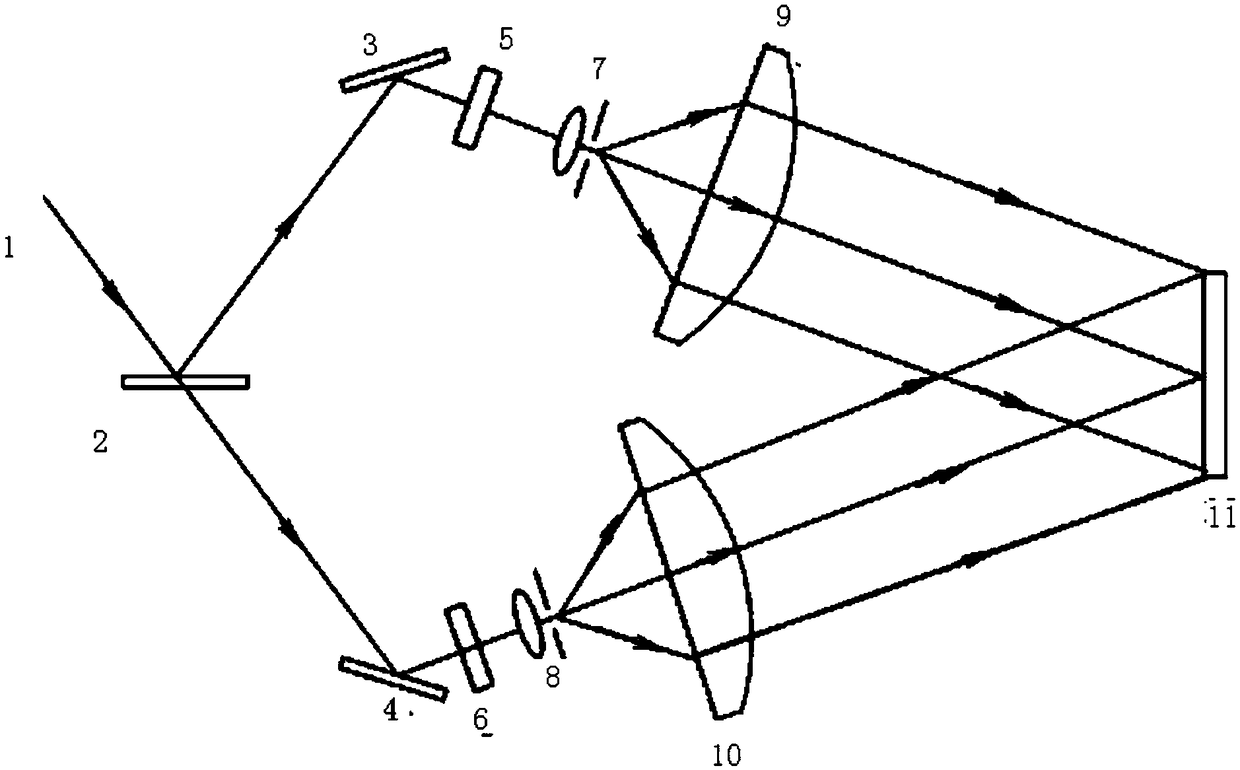

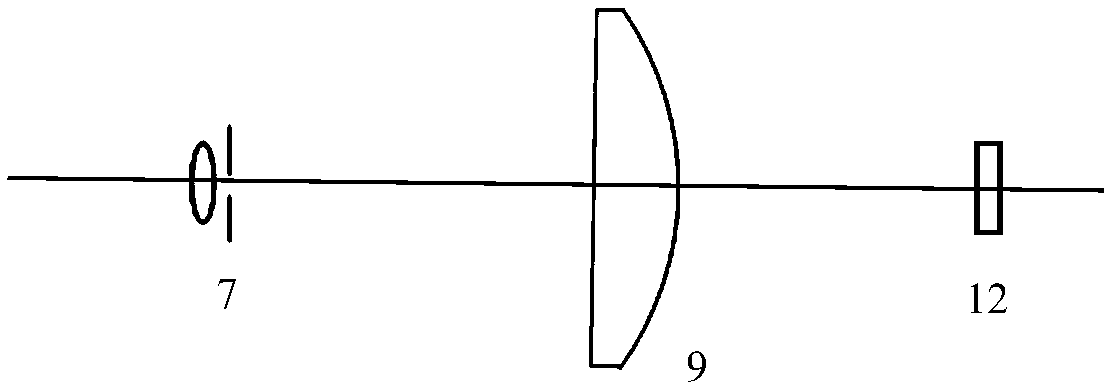

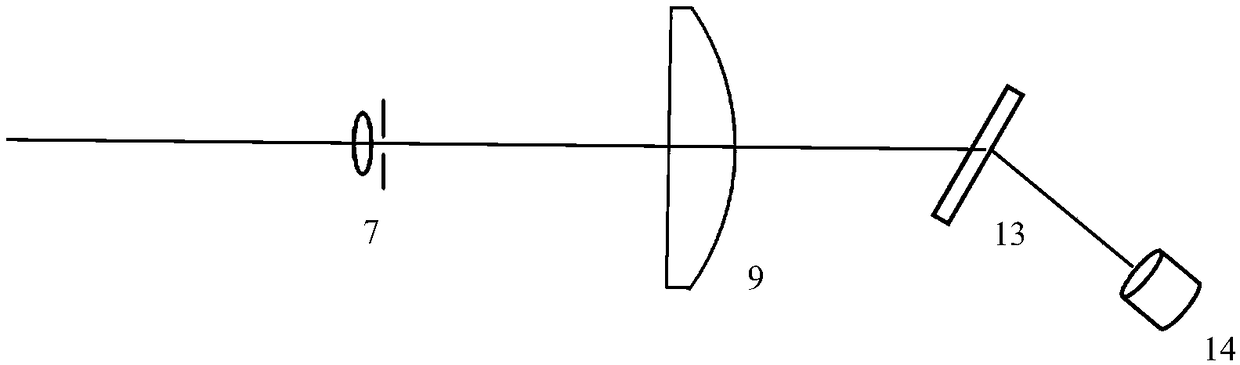

[0024] A method for adjusting the self-collimation of interference optical paths in a holographic grating photolithography system, the holographic grating photolithography system is used to make holographic gratings with parallel and equidistant stripes; the holographic grating photolithography system is as follows figure 1 Shown: including coherent light source 1, beam splitter 2, first mirror 3, second mirror 4, first aperture 5, second aperture 6, first pinhole filter 7, second pinhole filter device 8, the first collimating lens 9, the second collimating lens 10, the holographic recording dry plate 11 to be exposed, the plane mirror 12, the first volume Bragg grating 13, the first photodetector 14; the above-mentioned optical elements They are all placed on the holographic platform; the light emitted by the coherent light source is divided into the transmitted light path and the reflected light path after passing through the beam splitter; the first mirror, the first pinhol...

Embodiment 2

[0036] A photolithographic system for fabricating parallel and equally spaced striped holographic gratings, such as Figure 4 As shown: the holographic grating photolithography system is used to make a holographic grating with parallel and equally spaced stripes; the holographic grating photolithography system includes a coherent light source 1, a beam splitter 2, a first mirror 3, a second mirror 4, The first aperture 5, the second aperture 6, the first pinhole filter 7, the second pinhole filter 8, the first collimating lens 9, the second collimating lens 10; the first volume Bragg grating 13, the second Two-body Bragg grating 16, first photodetector 14, second photodetector 15;

[0037] The light emitted by the coherent light source is divided into the transmitted light path and the reflected light path after passing through the beam splitter; the first mirror, the first diaphragm, the first pinhole filter, and the first collimating lens are placed in sequence on the reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com