Bursting preventive shell tube structure and water heater

A hot water machine and shell tube technology, which is applied in the field of anti-expansion shell tube structure and hot water machine, can solve the problems of copper tube cracking, copper tube cracking, copper tube rupture, etc., and reduce the risk of copper tube rupture Risk, the effect of improving the anti-freeze cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

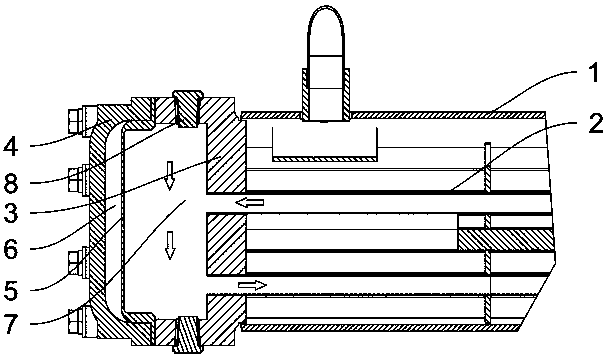

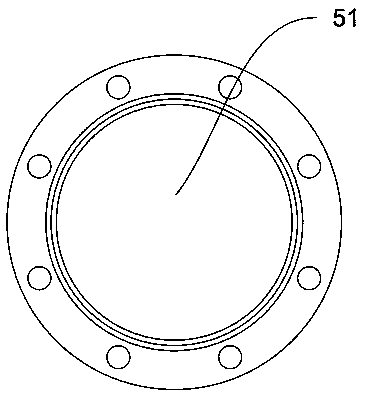

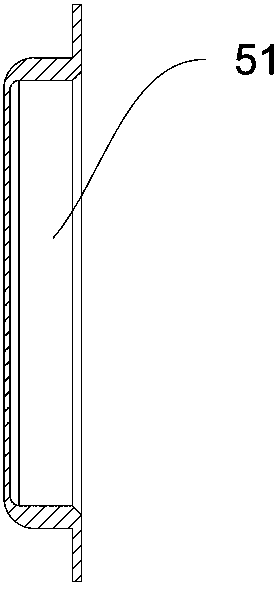

[0022] refer to figure 1 and figure 2 , an anti-expansion shell and tube structure provided for an embodiment, including a shell 1, a copper tube 2, a tube plate 3, a head 4, and an elastic separator 5. The opening of the shell 1 is fixed on the tube plate 3; the copper tube 2 is fixed on the tube plate 3, which is arranged inside the shell; the head 4 covers the tube plate 3, and is fixed firmly by screws; in this way, the elastic separator 5 connects the head 4 and the tube plate 3 The space between them is divided into two regional spaces, which are the water flow space 7 and the compensation space 6 respectively. The copper tube 2 communicates with the water flow space 7; In the water flow space 7 between, can not enter in the compensation space 6. When in a low temperature environment, that is, below 0°C, the increased volume of the water when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com