On-line diagnosis method for air leakage fault of sintering machine based on blind source separation and unilateral detection method

A technology of blind source separation and diagnosis method, which is applied in the field of online diagnosis of sintering machine air leakage faults, can solve the problems of lack of effective means for air leakage rate, high-temperature particles falling, energy waste of exhaust fans, etc., and achieve low implementation cost and reduce failures efficiency, reducing energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

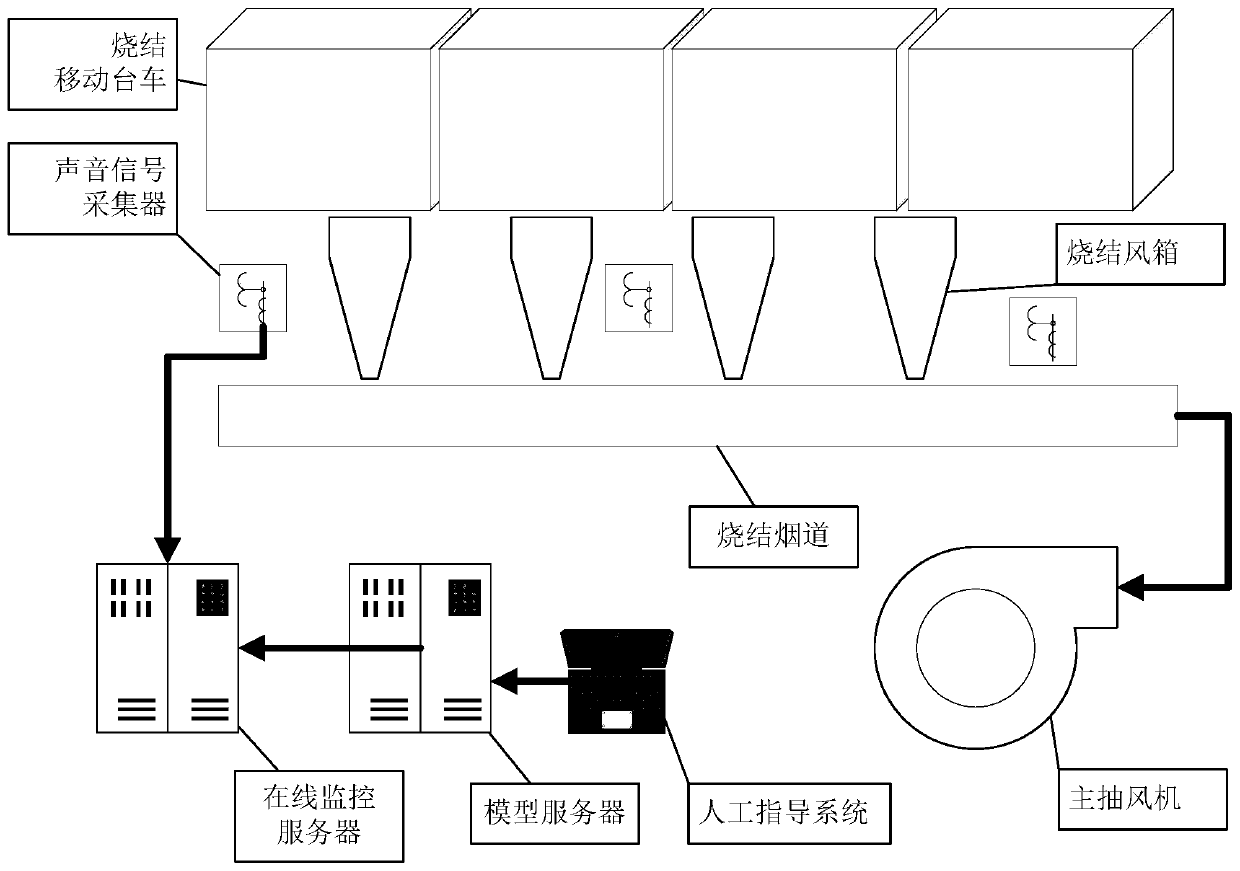

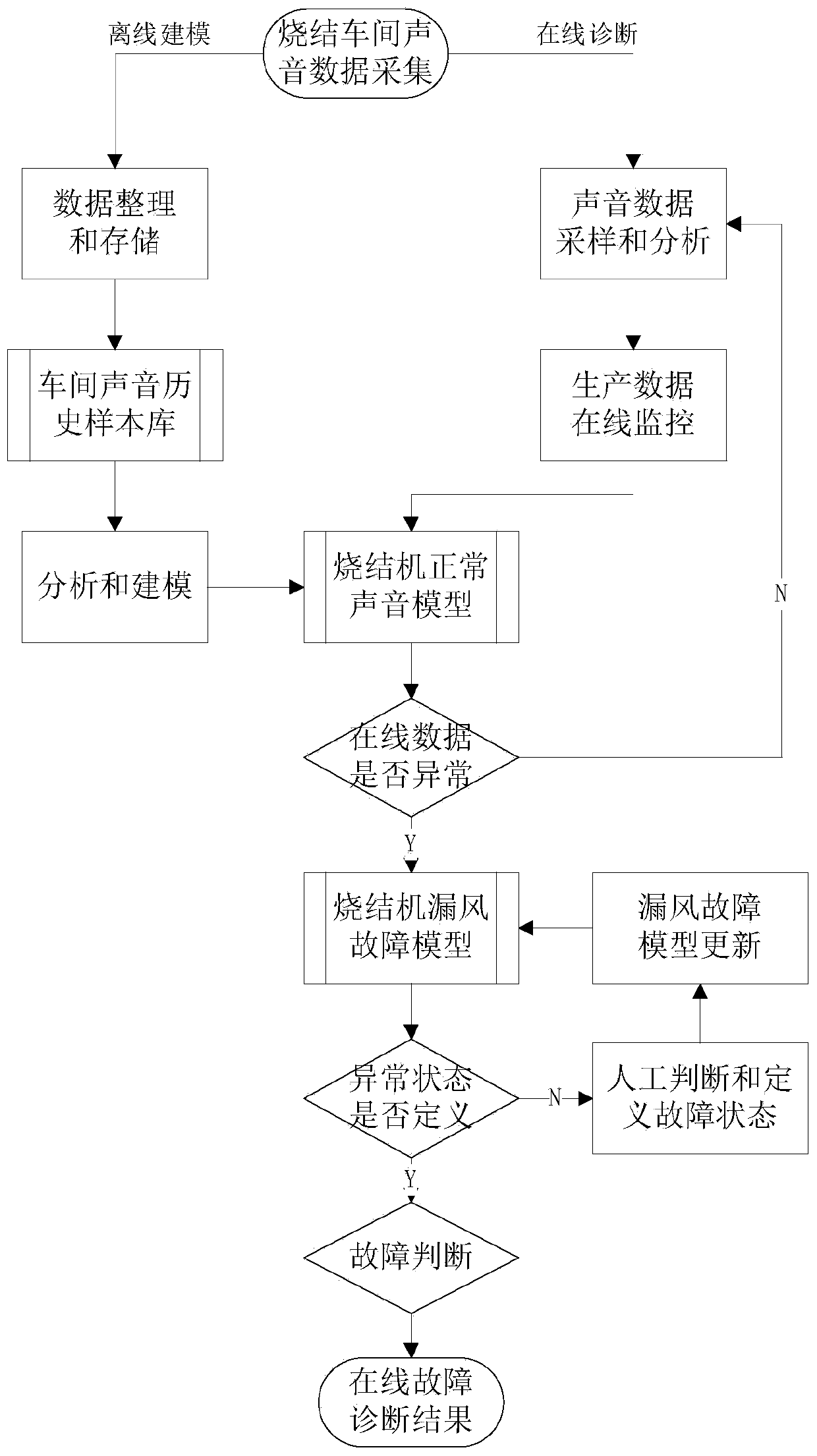

[0036] combine figure 1 with figure 2 The workshop where the sintering machine is located installs a number of sound signal collectors to provide detection signal sources for on-line fault diagnosis as on-site sensors. The method includes the following steps:

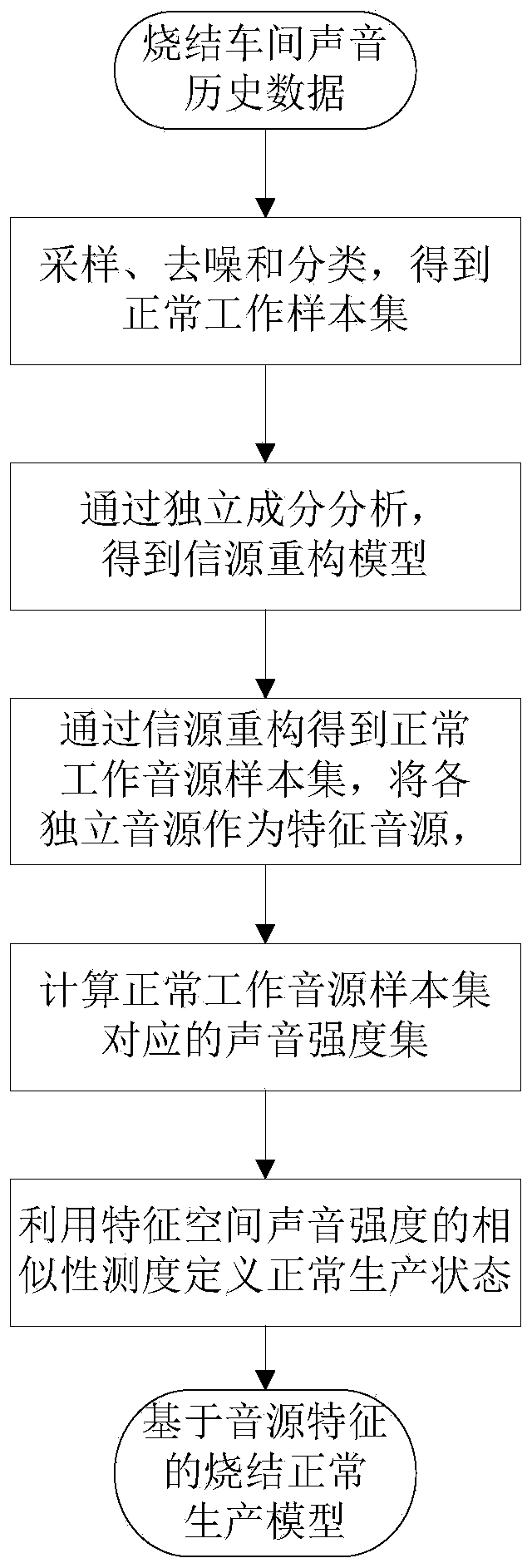

[0037] Step 1: Use the sound signal collector to collect the sound data of the sintering production workshop under normal working conditions, obtain the workshop sound history sample library, and obtain the offline normal sample set X after sampling and denoising processing normal ;

[0038] Step 2: Analyze the normal sample set obtained in Step 1 and establish a normal sound model of the sintering machine;

[0039] Step 3: Collect the sound data of the current sintering production workshop in real time to obtain online sound samples, compare the collected online sound samples with the normal sound model, and judge whether the online sound samples are abnormal according to the comparison results. If the data of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com