Crystal processing and drying device

A drying device and crystal technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of different drying efficiency of crystal plates, reduced drying efficiency, difficult and fast drying of crystal plates, etc., to improve drying quality and Drying efficiency, improving drying efficiency, avoiding the effect of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

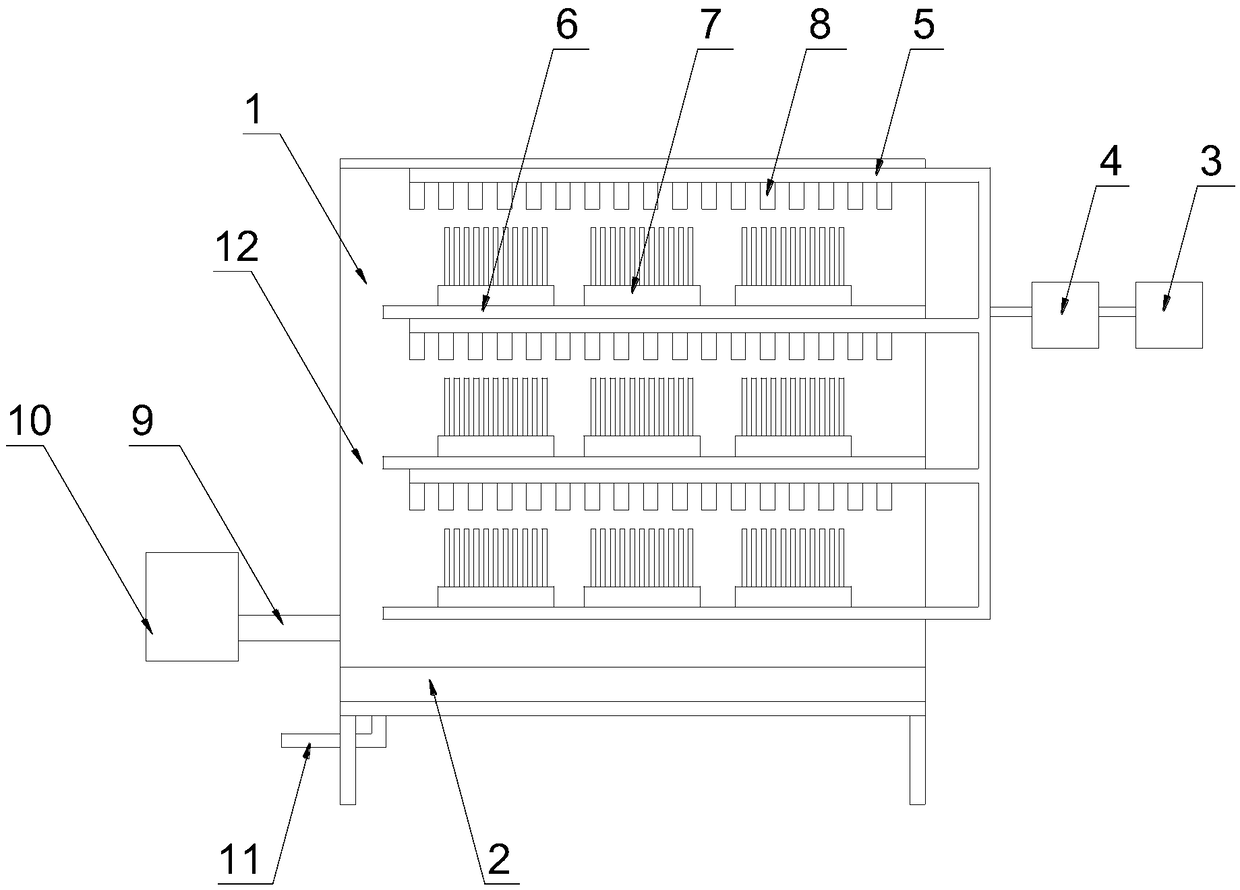

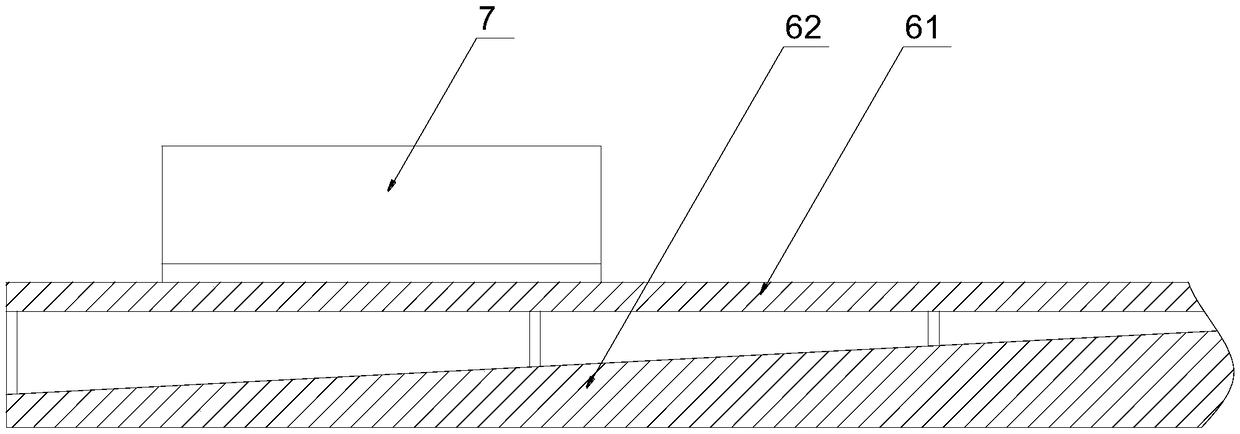

[0021] Such as Figure 1-2 as shown, figure 1 It is a schematic structural diagram of a crystal processing and drying device proposed by the present invention; figure 2 It is a partial structural schematic diagram of the crystal processing and drying device proposed by the present invention.

[0022] refer to Figure 1-2 , a kind of crystal processing drying device that the present invention proposes, comprises drying box 1, water collection tank 2, hot air blower 3, air filter 4, hot air pipe 5, nozzle 8, supporting plate 6, placement frame 7 and exhaust Tube 9; wherein, the crystal plate to be dried is placed on the placement rack 7;

[0023] A plurality of pallets 6 are arranged in the vertical direction; one end of the pallet 6 is fixedly arranged on the side wall of the drying box 1, and an opening 12 is formed between the other end and the side wall of the drying box 1; the bottom 62 of the pallet 6 It is arranged obliquely, and the lower end of the bottom 62 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com