A preparation method of paper-based folding actuator stimulated by multi-physics fields

A multi-physics and actuator technology, applied in chemical instruments and methods, papermaking, paper coatings, etc., can solve the problem of less work, and achieve the effect of simple method, simple and easy method, and stable conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

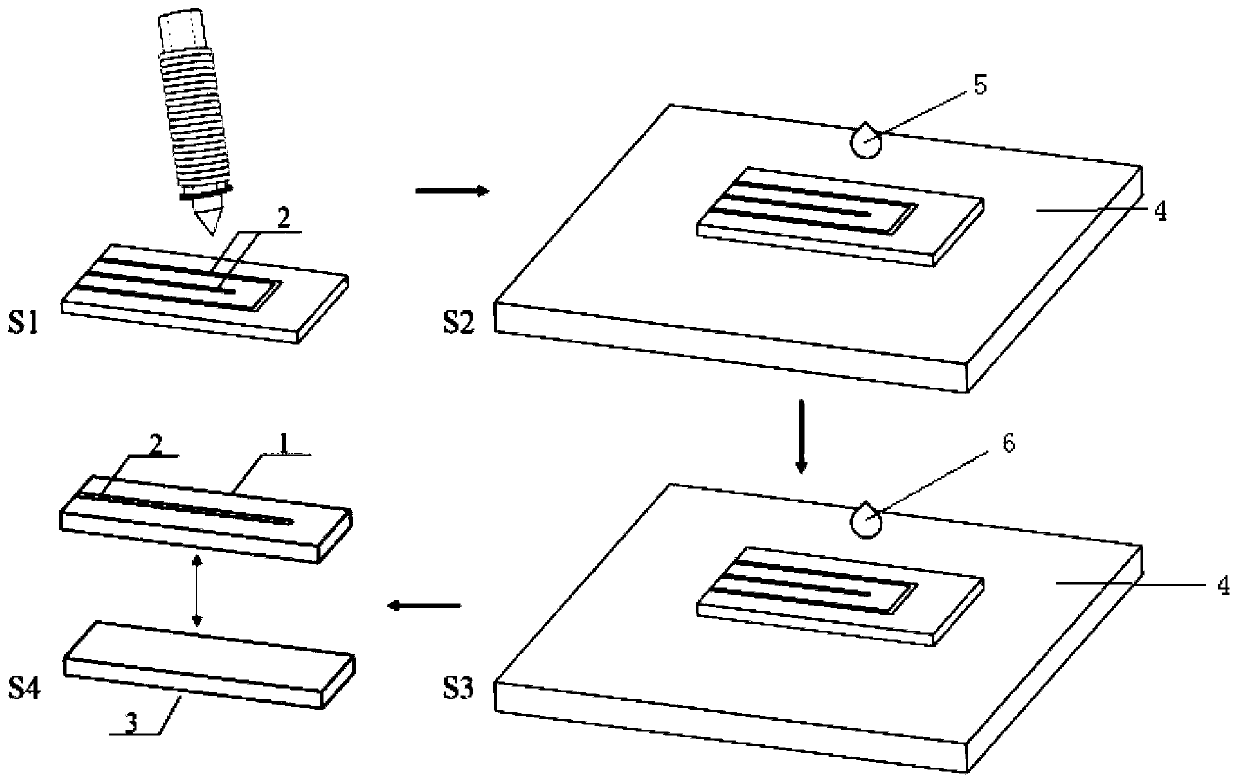

[0029] Embodiment 1, with reference to figure 1 , a method for preparing a paper-based bending actuator stimulated by a multiphysics field, comprising the following steps:

[0030] S1. Draw a rectangular wax wall 2 with an aspect ratio of 10cm / 2cm on Whatman grade 1 cellulose chromatography paper with an aspect ratio of 15cm / 15cm, and take the midpoint of a broadside as the starting point, along the parallel long sides Draw a paraffin line segment with a length of 9cm in the direction to build a U-shaped fluid channel;

[0031] S2. Fix the Whatman chromatography paper coated with wax wall 2 on the plexiglass 4 cut out in the middle with adhesive tape, and make the area with the paraffin pattern suspended in the air while pre-tensioning the chromatography paper;

[0032] Press 125μl / cm in the drawn U-shaped channel 2 PEDOT:PSS Clevios PH 1000 solution 5 was added dropwise to the standard, and air-dried at room temperature. After drying, the PEDOT:PSS / cellulose paper-based com...

Embodiment 2

[0035] Embodiment 2, with reference to figure 1 , a method for preparing a paper-based folding actuator stimulated by multiple physical fields, comprising the following steps:

[0036] S1. Cut out a square Whatman grade 1 chromatography paper with a side length of 6cm, and use a pencil to draw on the chromatography paper such as image 3 The wax wall 2 of the size equilateral triangle pattern (side length is respectively 5cm and 2.5cm) shown in b;

[0037] S2. Use adhesive tape to fix the Whatman chromatography paper coated with wax wall 2 on the plexiglass 4 cut in the middle, apply a slight pre-tension tension to the chromatography paper to avoid wrinkling, and then press 125 μl / cm 2 PEDOT:PSSClevios PH 1000 solution 5 was uniformly added dropwise to the standard, and air-dried at room temperature, after drying, PEDOT:PSS / cellulose paper-based composite material was obtained;

[0038] S3, press 75μl / cm on the dried PEDOT:PSS / cellulose paper composite material 2 The standa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com