Continuous preparation method of benzil or derivative of benzil

A technology of derivatives and benzil, which is applied in the field of continuous preparation of benzil or its derivatives, can solve the problems of high risk factor and large environmental pollution, and achieve the effects of high safety, environmental protection and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

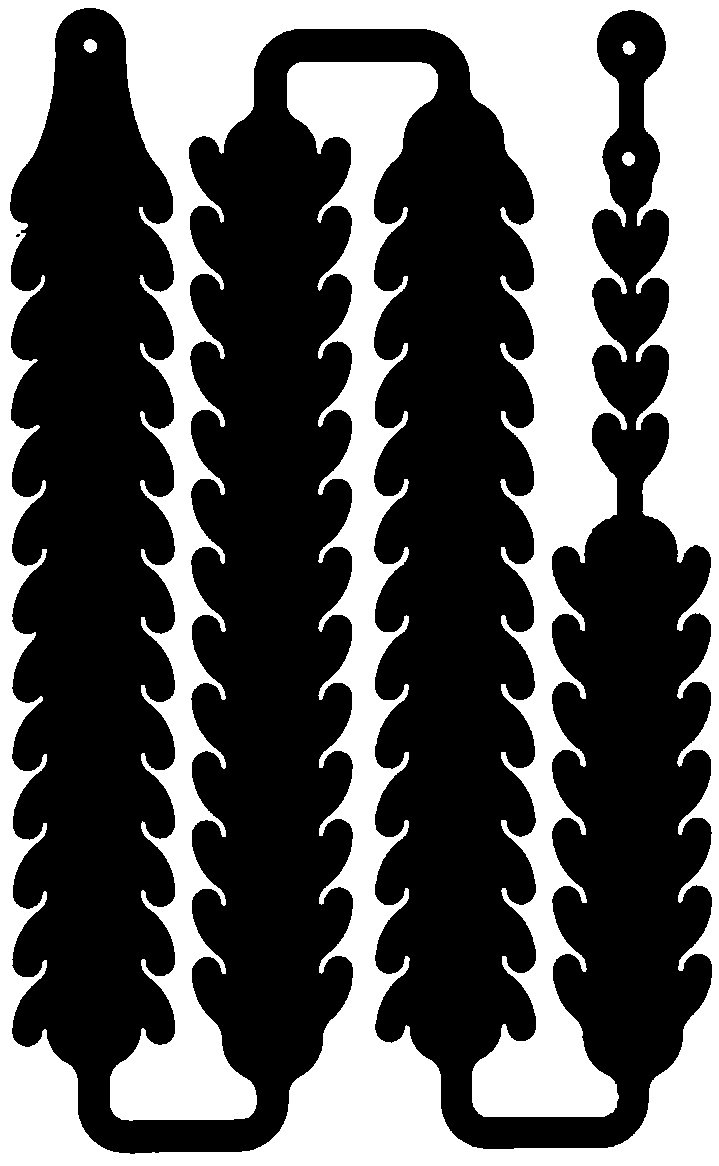

Image

Examples

preparation example Construction

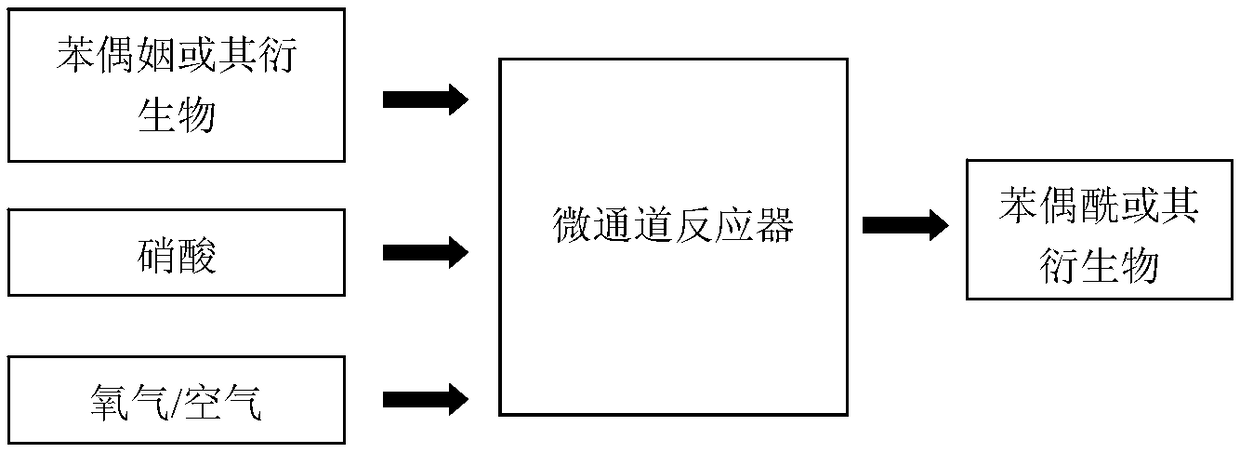

[0030] The invention provides a continuous preparation method of benzil or derivatives thereof, characterized in that:

[0031] In a microchannel reactor, benzoin or benzoin derivatives are reacted with nitric acid according to the following reaction formula to obtain benzil or derivatives thereof,

[0032]

[0033] Among them, R 1 and R 2 same or different, each H, halogen, substituted or unsubstituted C 1 -C 8 Alkyl, substituted or unsubstituted C 1 -C 8 Alkoxy, or nitro; wherein said C 1 -C 8 Alkyl or C 1 -C 8Alkoxy is optionally replaced by C 1 -C 8 Alkyl, C 1 -C 8 Alkoxy or halogen substitution.

[0034] Specific examples of halogen include fluorine, chlorine, bromine, and iodine.

[0035] as substituted or unsubstituted C 1 -C 8 Specific examples of the alkyl group include, for example, methyl, ethyl, n-propyl, isopropyl, n-butyl, isobutyl, sec-butyl, tert-butyl, n-pentyl, 1-methyl-n-butyl Base, 2-methyl-n-butyl, 3-methyl-n-butyl, 1,1-dimethyl-n-propy...

Embodiment 1

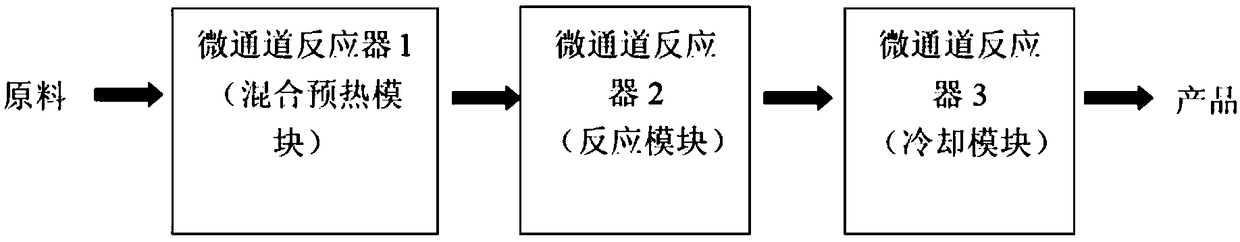

[0055] The molar flow ratio of benzoin and nitric acid in the microchannel reactor is 1:1, and the reaction raw materials benzoin and nitric acid are both fed in the form of solution. According to 100g benzoin, add 200g toluene to prepare the toluene solution of benzoin, the concentration is 2.05mol / L, the mass percent concentration of nitric acid is 40%, and the concentration is 7.91mol / L. The volume flow of benzoin solution is 50mL / min, and the volume flow of nitric acid is 12.9mL / min. Microchannel reactor 1 is a mixing preheating module with a controlled temperature of 130°C. The microchannel reactor 2 is a reaction module, and the reaction is carried out at normal pressure and 130° C., and the residence time is 20 s. The microchannel reactor 3 is a cooling module, and the temperature is controlled at 25°C. According to HPLC analysis, the conversion rate of the product benzil was 98.2%.

Embodiment 2

[0057] The molar flow ratio of benzoin and nitric acid in the microchannel reactor is 1:1.1, and the reaction raw materials benzoin and nitric acid are both fed in the form of solution. According to 100g benzoin, add 200g toluene to prepare the toluene solution of benzoin, the concentration is 2.05mol / L, the mass percent concentration of nitric acid is 40%, and the concentration is 7.91mol / L. The volume flow of benzoin solution is 50mL / min, and the volume flow of nitric acid is 14.2mL / min. Microchannel reactor 1 is a mixing preheating module with a controlled temperature of 130°C. The microchannel reactor 2 is a reaction module, and the reaction is carried out at normal pressure and 130° C., with a residence time of 10 s. The microchannel reactor 3 is a cooling module, and the temperature is controlled at 25°C. According to HPLC analysis, the conversion rate of the product benzil was 98.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com