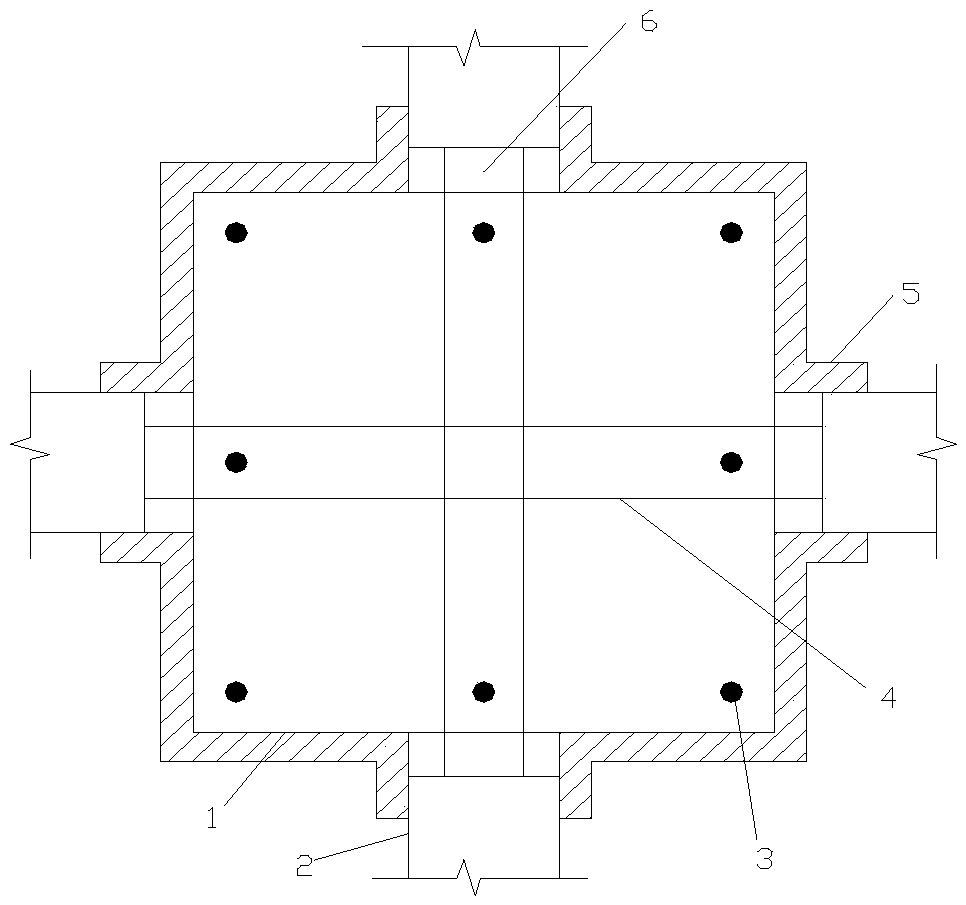

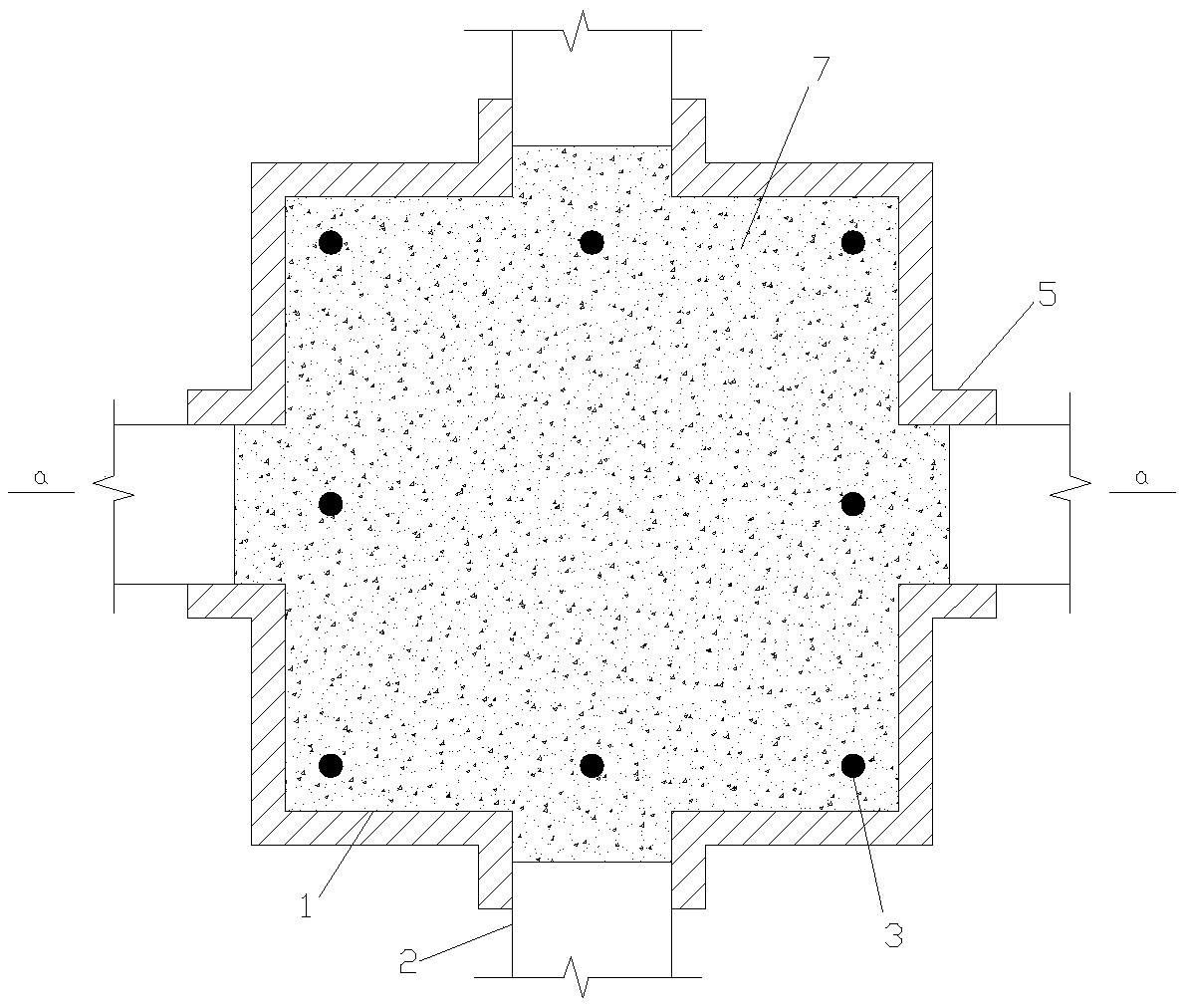

Phosphorus and magnesium material based cast-in-place phosphorus magnesium concrete of precast pillar joint and construction method

A technology of cast-in-place phosphorus-magnesium and prefabricated columns, which is applied in the direction of building and building structure to achieve the effects of excellent performance, lower dosage and lower porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A prefabricated column-beam joint cast-in-place phosphorus-magnesium concrete based on phosphorus-magnesium materials is prepared from the following raw materials in parts by weight: 80 parts of magnesium phosphate cement, 3 parts of admixtures, 10 parts of admixtures, and 100 parts of aggregates.

[0051] Further, the magnesium phosphate cement is a mixture of dead-burned magnesia and monoammonium phosphate, and the ratio of dead-burned magnesia and monoammonium phosphate is 4:1; Calcined and ground, the magnesium oxide content is 88%, and the fineness is 60 mesh; the nutrient content of the monoammonium phosphate is 72%, and the fineness is 60 mesh; the additives are retarder, defoamer and A mixture of water reducing agents; the defoamer is a silicone powder defoamer; the retarder is boric acid, the fineness of the boric acid is 60 mesh, and the purity is not less than 95% in terms of mass percentage; The admixture is a mixture of fly ash and metakaolin; the fineness ...

Embodiment 2

[0061] A prefabricated column-beam joint cast-in-place phosphorus-magnesium concrete based on phosphorus-magnesium materials is prepared from the following raw materials in parts by weight: 120 parts of magnesium phosphate cement, 18 parts of admixtures, 60 parts of admixtures, and 400 parts of aggregates.

[0062] Further, the magnesium phosphate cement is a mixture of dead-burned magnesia and monoammonium phosphate, and the ratio of dead-burned magnesia and monoammonium phosphate is 1:1; It is obtained by calcining and grinding, its magnesium oxide content is 95%, and its fineness is 400 mesh; the nutrient content of said monoammonium phosphate is 72%, and its fineness is 400 mesh; said admixture is retarder, defoamer and A mixture of water reducing agents; the defoamer is a silicone powder defoamer; the retarder is borax, the fineness of the borax is 400 mesh, and the purity is not less than 95% in terms of mass percentage; The admixture is a mixture of fly ash and metakaol...

Embodiment 3

[0072] A prefabricated column-beam joint cast-in-place phosphorus-magnesium concrete based on phosphorus-magnesium materials is prepared from the following raw materials in parts by weight: 83 parts of magnesium phosphate cement, 8 parts of admixtures, 12 parts of admixtures, and 105 parts of aggregates.

[0073] Further, the magnesium phosphate cement is a mixture of dead-burned magnesia and monoammonium phosphate, and the ratio of dead-burned magnesia and monoammonium phosphate is 3.5:1; It is obtained by calcining and grinding, its magnesium oxide content is 89%, and its fineness is 70 mesh; the nutrient content of said monoammonium phosphate is 72%, and its fineness is 70 mesh; said additives are retarder, defoamer and A mixture of water reducing agents; the defoamer is a silicone powder defoamer; the retarder is borax, the fineness of the borax is 70 mesh, and the purity is not less than 95% in terms of mass percentage; The admixture is a mixture of fly ash and metakaolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com