Method for preparing reinforced gypsum powder, reinforced gypsum powder and plastering gypsum

A technology of gypsum powder and phosphogypsum, applied in the field of reinforced gypsum powder and plastering gypsum, and preparation of reinforced gypsum powder, which can solve the problems of easy damage, restrictions on the application of phosphogypsum-made building gypsum powder, and uneven product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing reinforced gypsum powder, prepared according to the following steps:

[0023] Step 1, modification: crushing and modifying calcined gypsum to obtain modified gypsum powder;

[0024] Step 2. Purification: removing impurities without gelling properties in the modified gypsum powder to obtain reinforced gypsum powder.

[0025] Wherein, the phosphogypsum is firstly heated and dried to reduce the water content to 8-10%, and then calcined at 130-150° C. for 10-60 minutes to obtain calcined gypsum, and then the modification treatment in the first step is carried out. The calcination is carried out in a FC compartment calciner, which is an existing equipment (CN203878066U). A large amount of external water and internal water and the most harmful components in phosphogypsum are mainly residual organic phosphorus, inorganic phosphorus and ammonium phosphate. If they are removed or turned into harmless components, then phosphogypsum is very easy to use. "F...

Embodiment 2

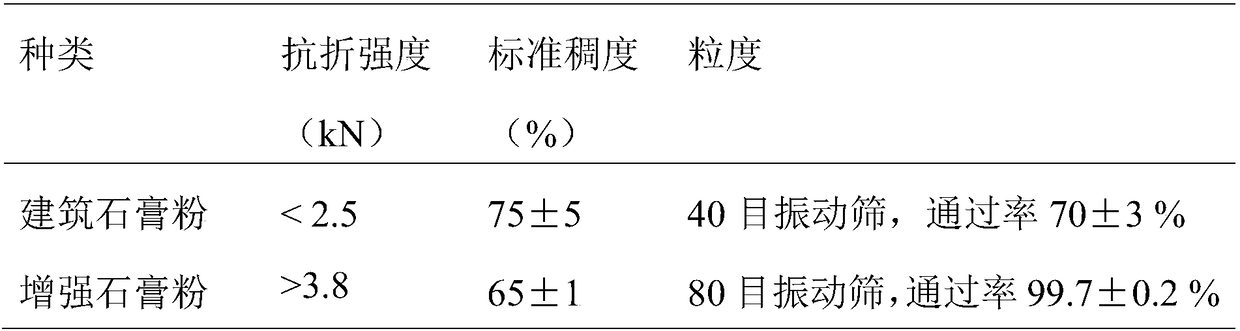

[0030] A kind of reinforced gypsum powder, prepared by the method of embodiment 1. The properties of the enhanced gypsum powder and common building gypsum powder are compared in Table 1. The strength test is to stir the gypsum powder with water, condense it into a standard test block of 40mm×40mm×100mm, and measure it on a mechanical testing machine. It can be seen that the performance of reinforced gypsum powder is different from that of ordinary building gypsum powder after crushing, modification and purification. Compared with traditional gypsum, the strength of reinforced gypsum is significantly improved, the particle size is reduced and uniformly distributed, the standard consistency is stable, and the hydration paste has good flexibility.

[0031] After testing, the setting time of the standard consistency of the reinforced gypsum powder is: initial setting time 6 minutes, final setting time 11 minutes; after watering and setting, the strength of 2 hours is: flexural st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com