Treatment method suitable for acidic rinsing wastewater in metal processing process

A metal processing and treatment method technology, applied in the field of water treatment, can solve the problems of additives, polluted raw materials, recycle of difficult acid rinsing wastewater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

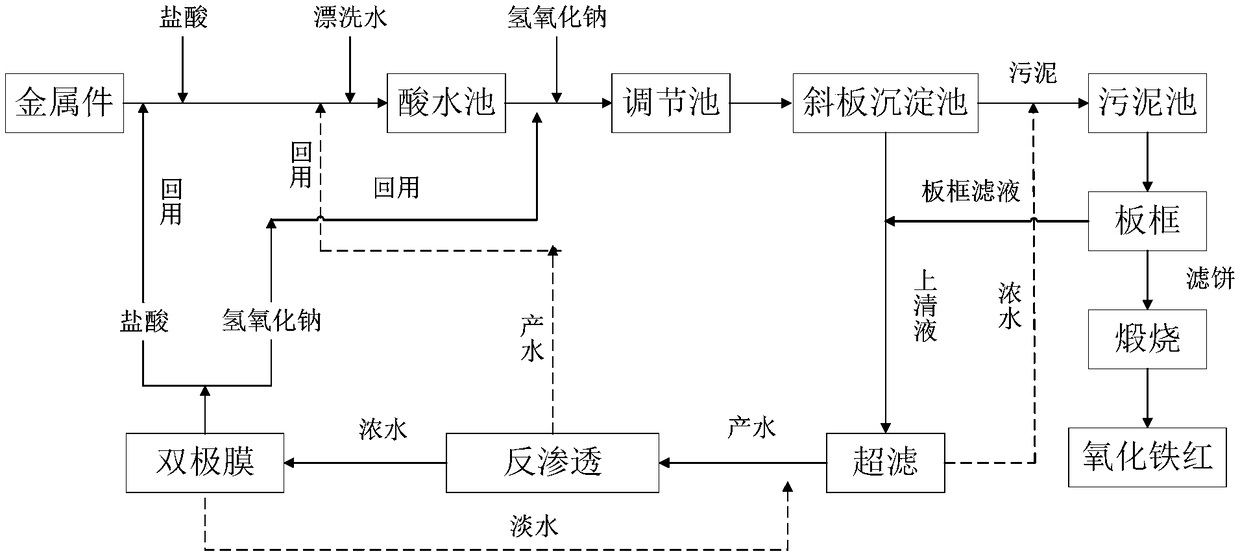

Embodiment 1

[0045] Hydrochloric acid pickling:

[0046] During the galvanizing production process of a certain factory, hydrochloric acid is used for pickling, and the pH of the generated acidic rinsing wastewater is 2.5, which is passed into the first acid pool; the wastewater is pumped into the first adjustment pool, and the pH value is adjusted to 7.1, and use a blower to aerate, so that all the sediment is converted into ferric hydroxide; then enter the first inclined plate sedimentation tank, the ferric hydroxide sinks to the bottom, and is discharged into the first sludge tank for treatment; the upper part of the first inclined plate sedimentation tank The clear liquid is a sodium chloride salt solution with a TDS content of 3800mg / L, which enters the first ultrafiltration (using ceramic membrane) system for treatment; the first concentrated water obtained by the ceramic membrane treatment is discharged into the first sludge tank for treatment, and the ceramic membrane The TDS conte...

Embodiment 2

[0049] Hydrochloric acid pickling:

[0050] During the galvanizing production process of a certain factory, hydrochloric acid is used for pickling, and the pH of the generated acidic rinsing wastewater is 2, which is passed into the first acid pool; the wastewater is pumped into the first adjustment pool, and the pH value is adjusted to 6.9, and use a blower to aerate, so that all the sediment is converted into ferric hydroxide; then enter the first inclined plate sedimentation tank, the ferric hydroxide sinks to the bottom, and is discharged into the first sludge tank for treatment; the upper part of the first inclined plate sedimentation tank The clear liquid is a sodium chloride salt solution with a TDS content of 3360mg / L, and enters the first ultrafiltration (using ceramic membrane) system for treatment; the first concentrated water obtained by the ceramic membrane treatment is discharged into the first sludge tank for treatment, and the ceramic membrane The TDS content o...

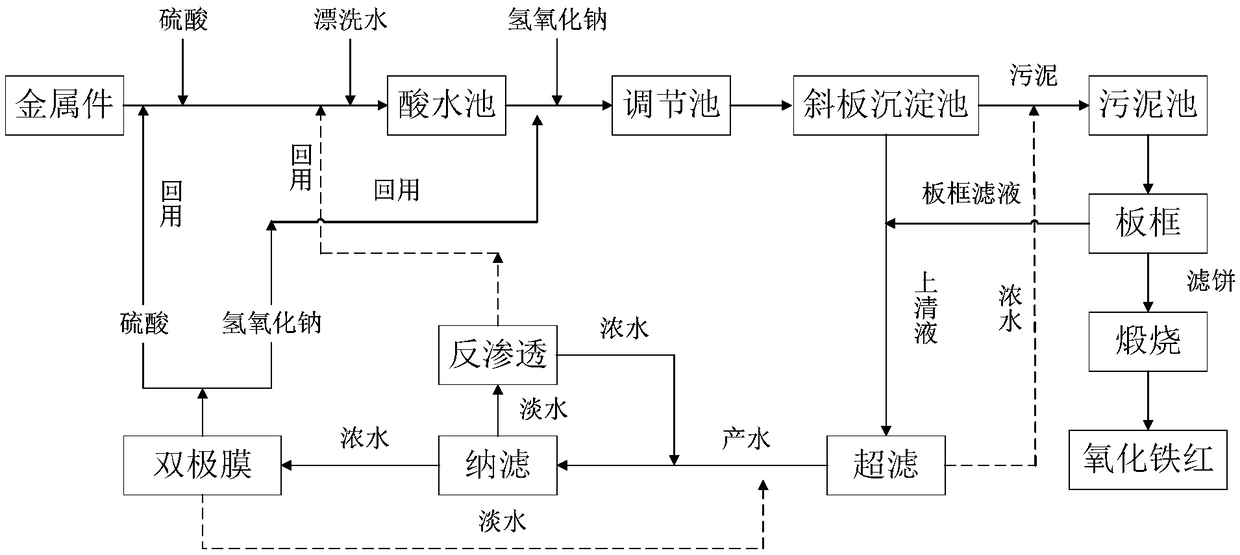

Embodiment 3

[0053] Sulfuric acid pickling:

[0054]During the galvanizing production process of a certain factory, sulfuric acid is used for pickling, and the pH of the generated acidic rinsing wastewater is 1.5, which is passed into the second acid pool; the wastewater is pumped into the second adjustment pool, and the pH value is adjusted to 7.0 with sodium hydroxide , and use a blower to aerate, so that all the sediment is converted into ferric hydroxide; then enter the second inclined plate sedimentation tank, the ferric hydroxide sinks to the bottom, and is discharged into the second sludge tank for treatment; the supernatant of the second inclined plate sedimentation tank Liquid is sodium sulfate salt solution, TDS content is 5680mg / L, enters the second ultrafiltration (using ceramic membrane) system to process; The TDS content of the first product water is 5680mg / L, and then through the nanofiltration system (using cross-linked aromatic polyamide anti-fouling nanofiltration membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com