Soft manipulator embedded with rubber hoses

A technology of rubber hoses and manipulators, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of complex environment, poor environmental adaptability, and low transmission efficiency, and achieve the effect of eliminating complex processes and improving adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

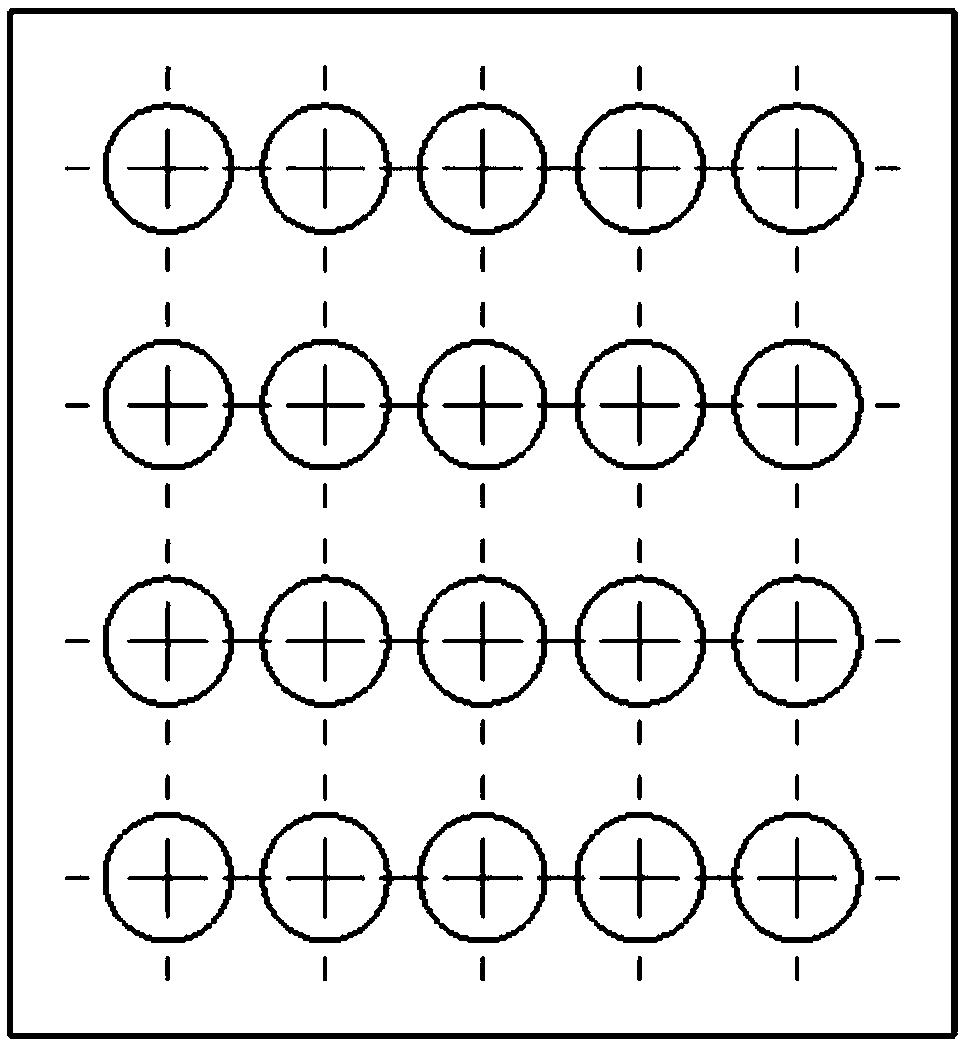

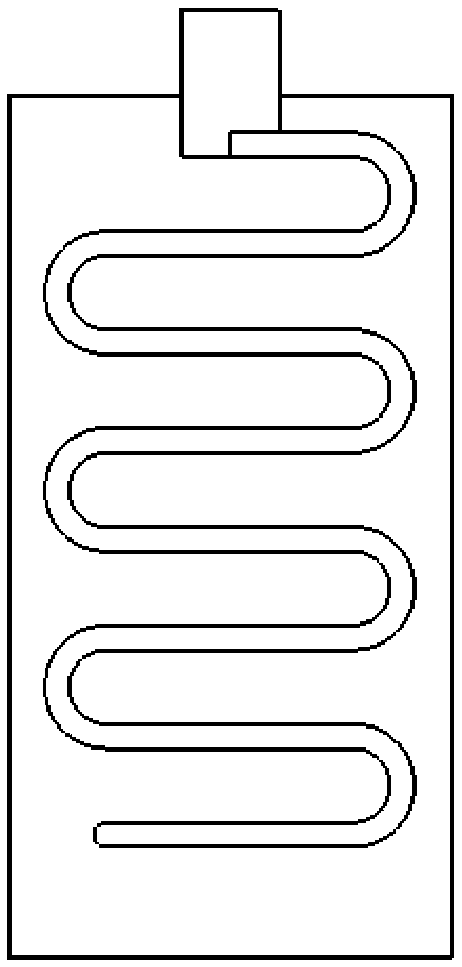

[0030] Such as Figure 6 As shown, a soft manipulator embedded in a rubber hose includes 3 soft tentacles of the same specification and a rigid frame for installing the soft tentacles. The inside of the tentacles is injected with layered glue. One layer is a composite layer of silica gel and fiber, and rubber hose 11 is laid in a continuous U shape in the middle layer of silica gel. The rubber hose is a high-elastic latex tube, and the outer layer is silica gel. Set the length of each tentacle as L, the width as W, and the width of the continuous U-shaped laying of the rubber hose as W 1 , The opening distance of a single U-shape is L 1 , where 1 / 21 / W1 / L1 / W,L 1 The value of / L, under the condition that the air pressure P of the air pump is constant, the bending degree of the tentacle is the same as W 1 / W is proportional to L 1 / L is inversely proportional to W 1 The larger the / W, the wider the U-shaped width of the rubber hose laying, L 1 The smaller the / L, the den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width w | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com