Simple clamping mechanism special for steel pipe

A technology of clamping mechanism and steel pipe, applied in the direction of clamping device, clamping, metal processing machine parts, etc., can solve the problems of steel pipe connection error, steel pipe position offset, etc., to reduce offset, reduce error, and improve firmness and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

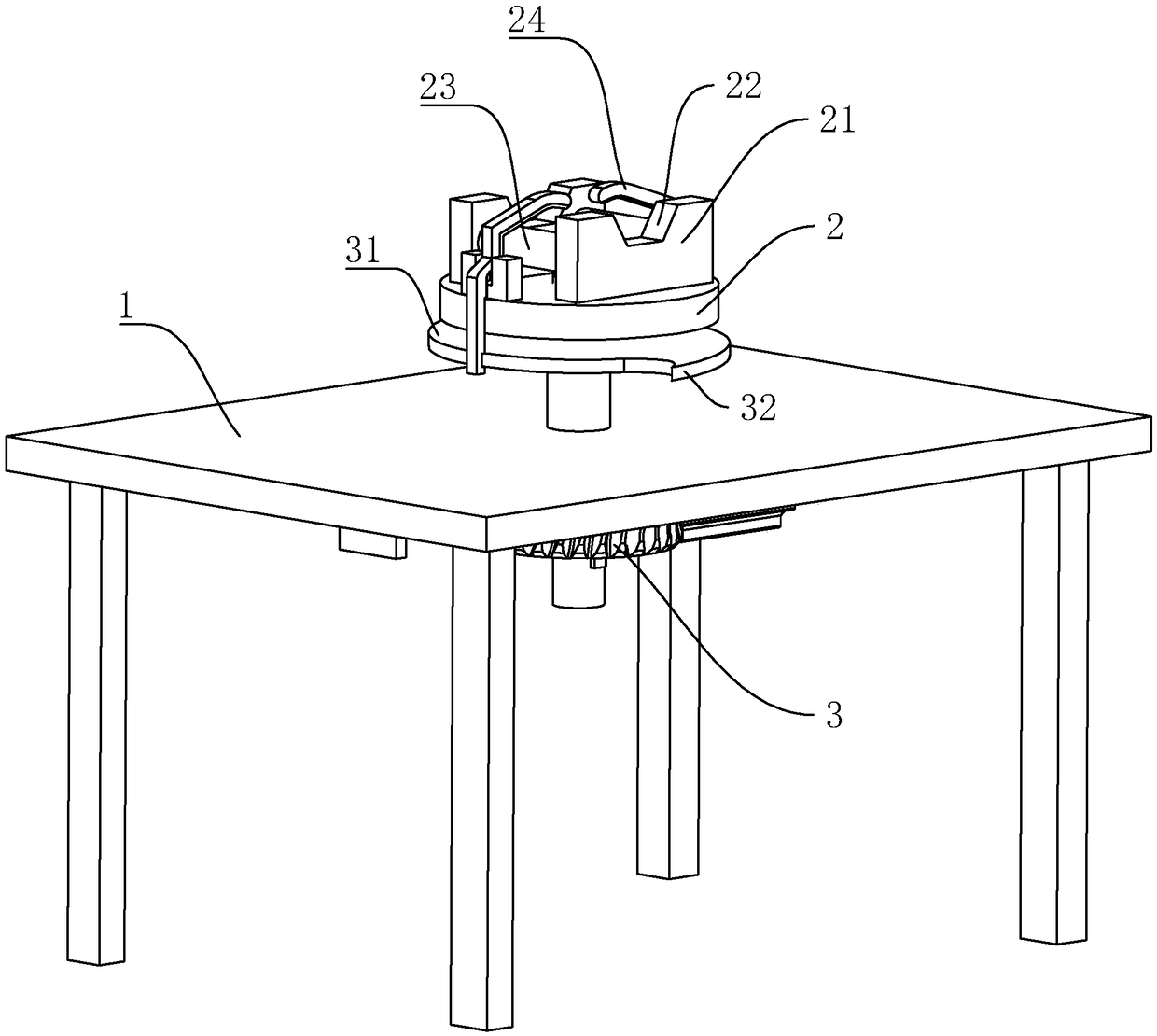

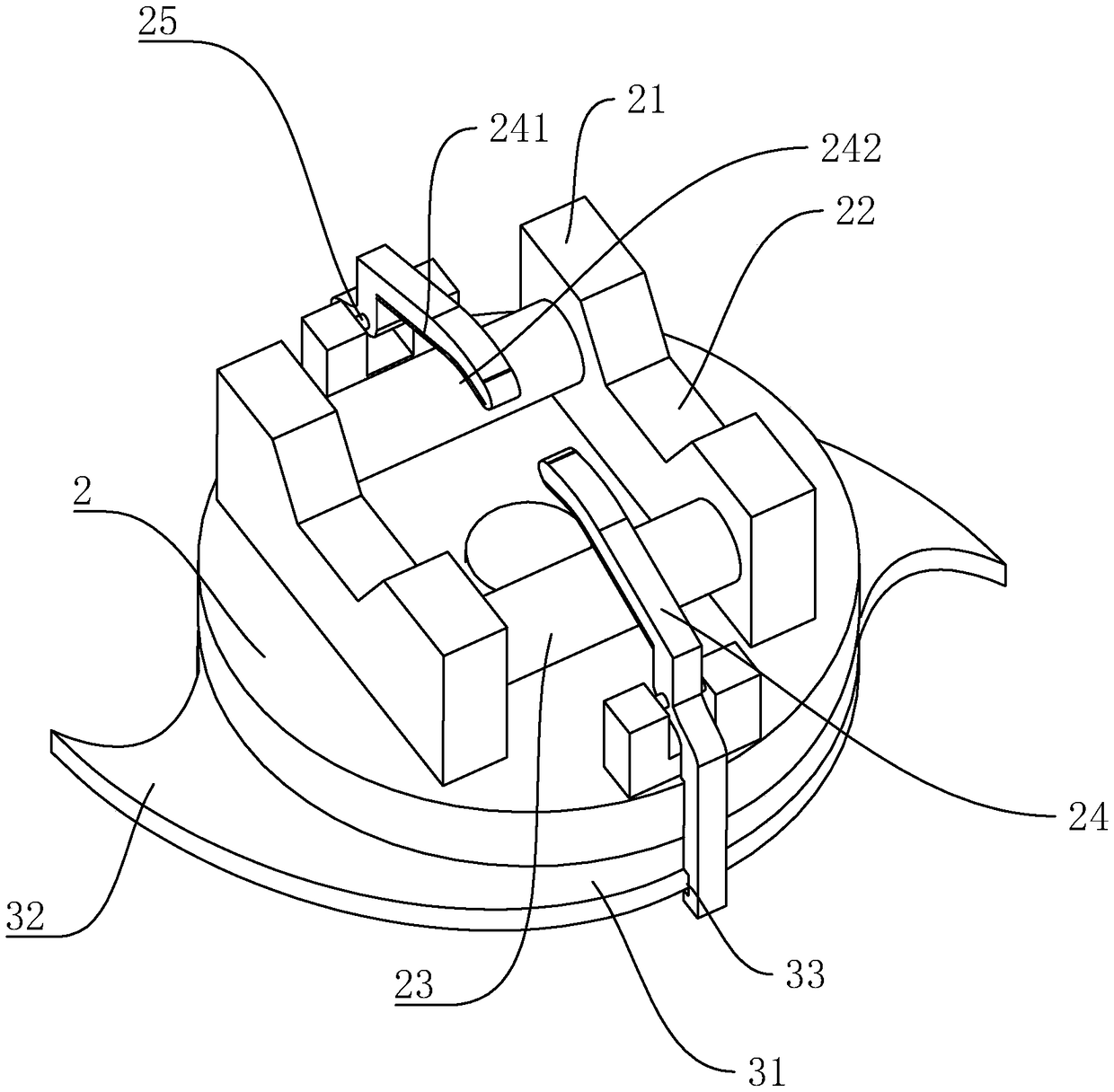

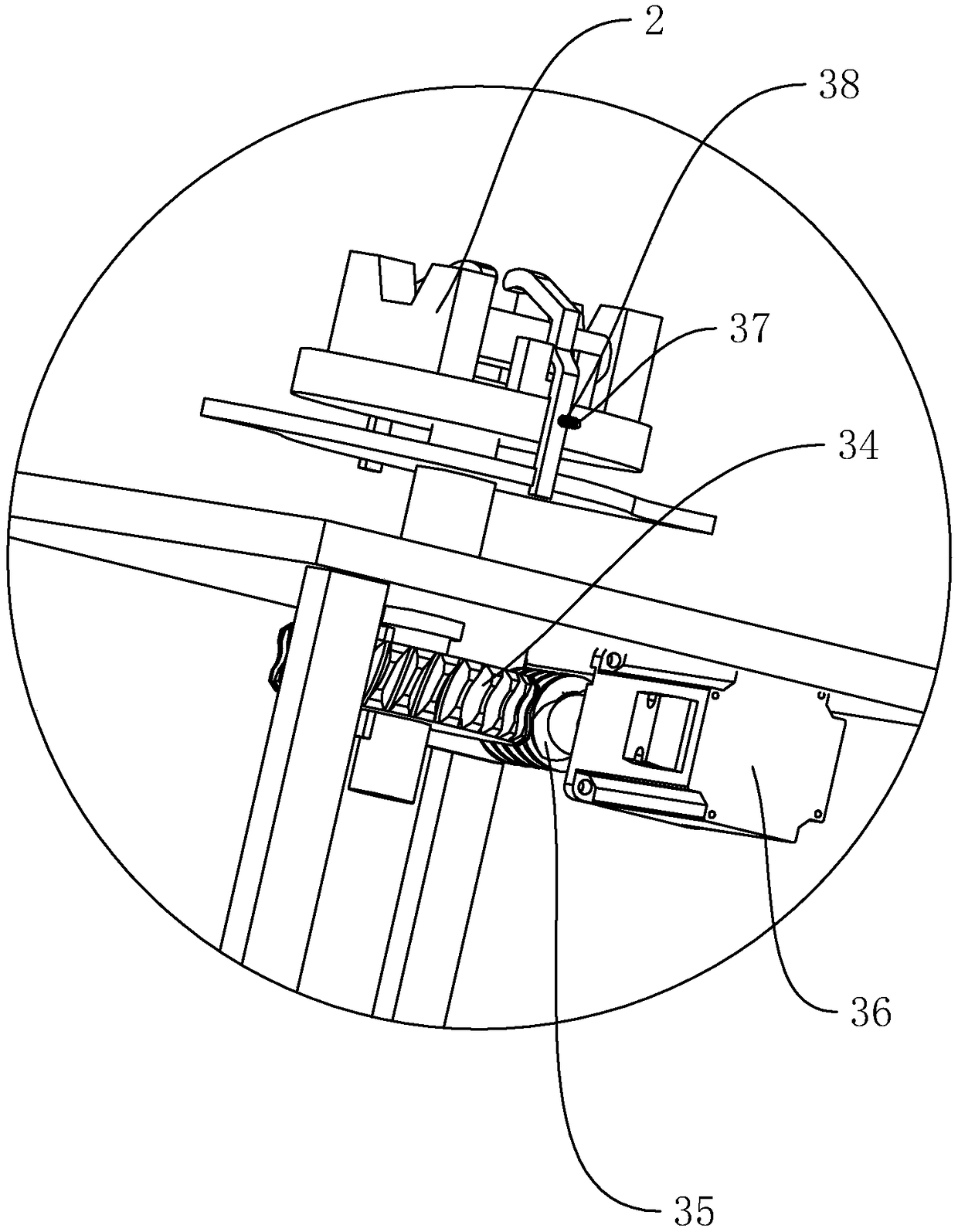

[0031] Embodiment 1, a kind of easy and simple steel pipe special-purpose clamping mechanism, such as figure 1 , figure 2 and image 3 As shown, it includes a rectangular frame 1 as a whole. The center position of the frame 1 is fixedly connected with a fixed plate. Two splints 21 arranged parallel to each other are integrally arranged on the fixed plate. Clamping grooves 22 are provided in the splint 21. Holding groove 22 can be used for accommodating steel pipe, is provided with rolling wheel 23 between two splints 21, and rolling wheel 23 is provided with two, and the setting of rolling wheel 23 can avoid that steel pipe is pressed and produces deformation during clamping process.

[0032] Such as figure 1 , figure 2 and image 3 As shown, the fixed disc 2 is provided with several clamping jaws 24 that are rotatably connected to the fixed disc 2. The clamping jaws 24 are set at the positions corresponding to the rolling wheels 23 for clamping the steel pipe in the cla...

Embodiment 2

[0035] Embodiment 2, a kind of easy and simple clamping mechanism special for steel pipe, such as Figure 4 As shown, the difference from Embodiment 1 is that the driving member 3 includes a driving cylinder 39 fixed on the frame 1 perpendicular to the horizontal plane, and the output shaft of the driving cylinder 39 is provided with several linkages hinged to the corresponding jaws 24. Rod 391, one end of linkage rod 391 is hinged on the jaw 24, and the other end is hinged on the output shaft of the driving cylinder 39. The clamping jaws 24 are arranged in a corner shape, and the middle position of the clamping jaws 24 is connected to the fixed disk 2 , and the position of the clamping jaws 24 corresponding to the rolling wheel 23 is provided with a clamping groove 22 .

[0036] The output shaft of the cylinder moves, which drives the linkage rod 391 to move, thereby pulling the jaws 24 to rotate around the hinge shaft, thereby completing the clamping and loosening of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com