A filter element used in high viscosity occasions and its production method

A production method and high-viscosity technology, applied in the direction of separation methods, chemical instruments and methods, fixed filter elements, etc., can solve the problems of large filter element volume, high maintenance costs, and low dirt holding capacity, and achieve high interception efficiency, The effect of saving production cost and high dirt carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

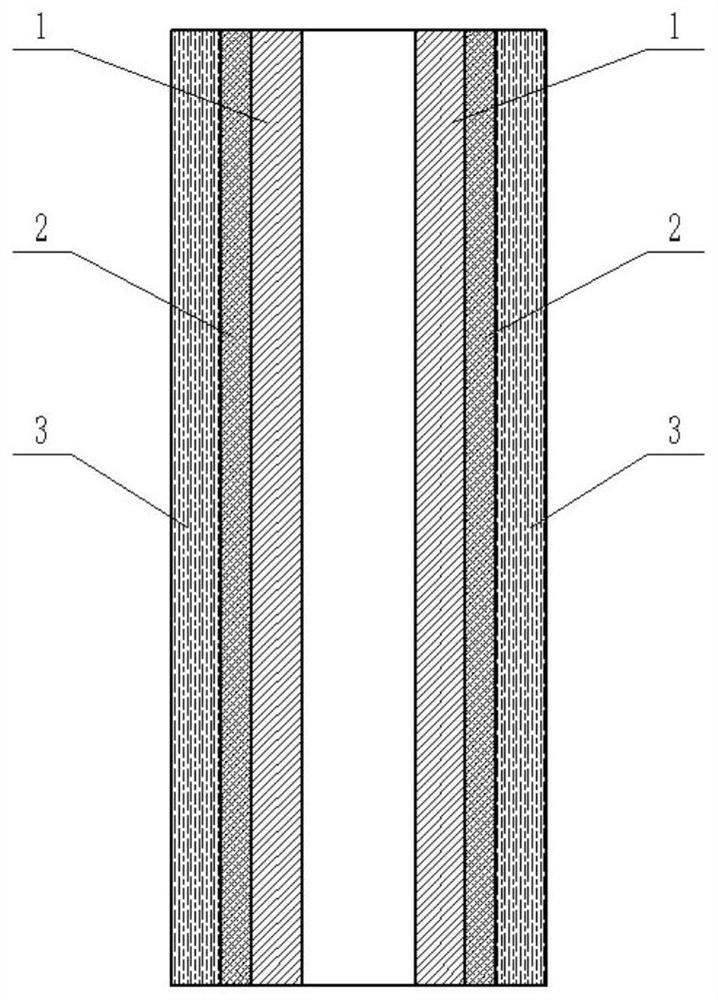

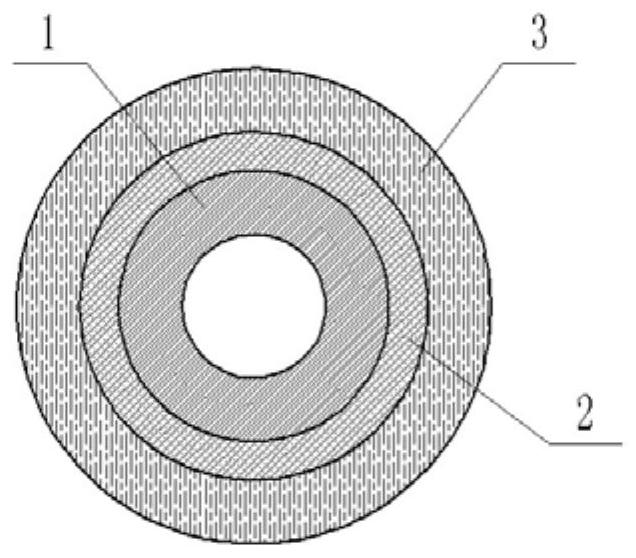

[0034] A method for producing a filter element applied to a high-viscosity occasion, comprising the following steps:

[0035] (1) Prepare the inner core: introduce one end of the bicomponent fiber non-woven filter membrane with a width of 1m into the winding roller of the winding machine, and use the pressure roller to compress it tightly, and circulate the hot air. The temperature of the circulating hot air is 90°C. Slightly melt the surface of the fiber shell PE material of the bicomponent fiber non-woven filter membrane; turn on the winding machine, set the line speed to 0.05m / min, set the tension value at 6N, and the bicomponent fiber non-woven filter membrane is rolled Winding on the roll to form a winding film; when the meter counter on the winding machine counts to 1m, the length of the winding film reaches 1m, the winding machine stops winding, and the bi-component fiber non-woven filter membrane is cut. make the inner core;

[0036](2) Prepare the intermediate filter...

Embodiment 2

[0040] A method for producing a filter element applied to a high-viscosity occasion, comprising the following steps:

[0041] (1) Prepare the inner core: introduce one end of the two-component fiber non-woven filter membrane with a width of 1.2m into the winding roller of the winding machine, and press it tightly with a pressure roller, and circulate hot air with a temperature of 92°C , so that the surface of the fiber shell PE material of the two-component fiber non-woven filter membrane is slightly melted; open the winding machine, set the line speed to 0.5m / min, set the tension value at 7N, and the two-component fiber non-woven filter membrane is at Winding on the winding roller to form a winding film; when the meter counter on the winding machine counts to 0.2m, the length of the winding film reaches 0.2m, the winding machine stops winding, and the bicomponent fiber non-woven fabric is cut filter membrane to make the inner core;

[0042] (2) Prepare the middle filter laye...

Embodiment 3

[0046] A method for producing a filter element applied to a high-viscosity occasion, comprising the following steps:

[0047] (1) Prepare the inner core: introduce one end of the two-component fiber non-woven filter membrane with a width of 2m into the winding roller of the winding machine, and press it tightly with a pressure roller, and circulate hot air with a temperature of 100°C. Slightly melt the surface of the fiber shell PE material of the bicomponent fiber non-woven filter membrane; turn on the winding machine, set the line speed to 0.7m / min, set the tension value at 10N, and the bicomponent fiber non-woven filter membrane is rolled Winding on the roll to form a winding film; when the meter meter on the winding machine counts to 1.2m, the length of the winding film reaches 1.2m, the winding machine stops winding, and the bi-component fiber non-woven filter is cut Membrane, making the inner core;

[0048] (2) Prepare the intermediate filter layer: import one end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com