Powder filling production line for TDP moxibustion

A production line and filling technology, which is applied to heating appliances for treatment, cooling appliances for treatment, treatment, etc., can solve the problem of uneven discharge of moxibustion plaster powder, so as to avoid insufficient powder and accelerate scattering The effect of speed and ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

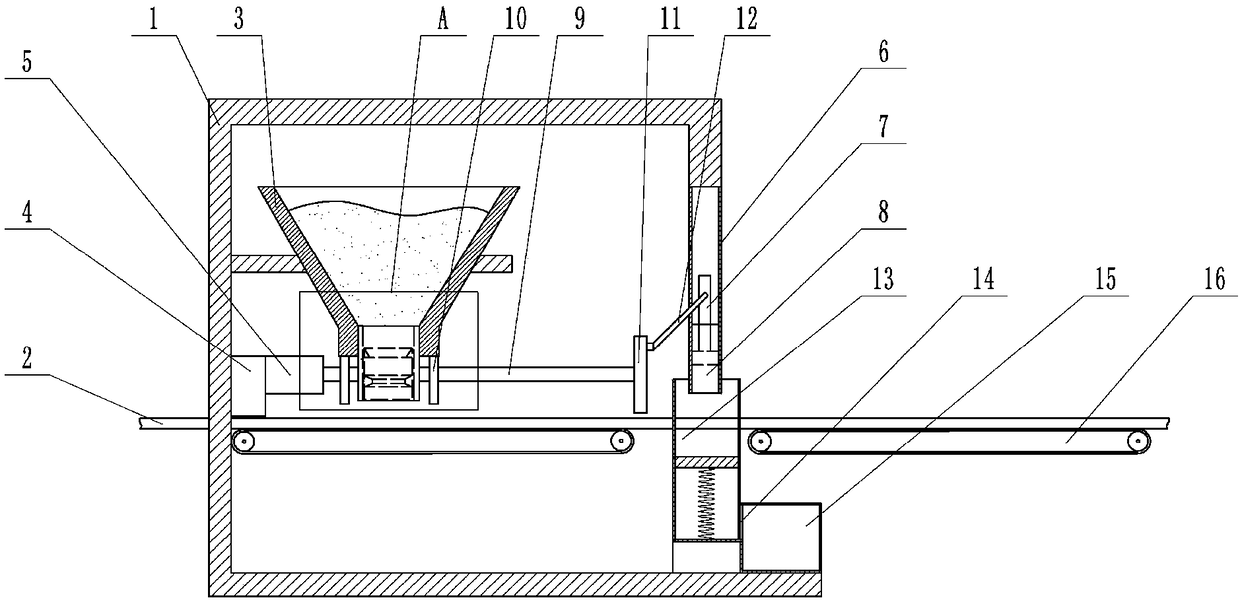

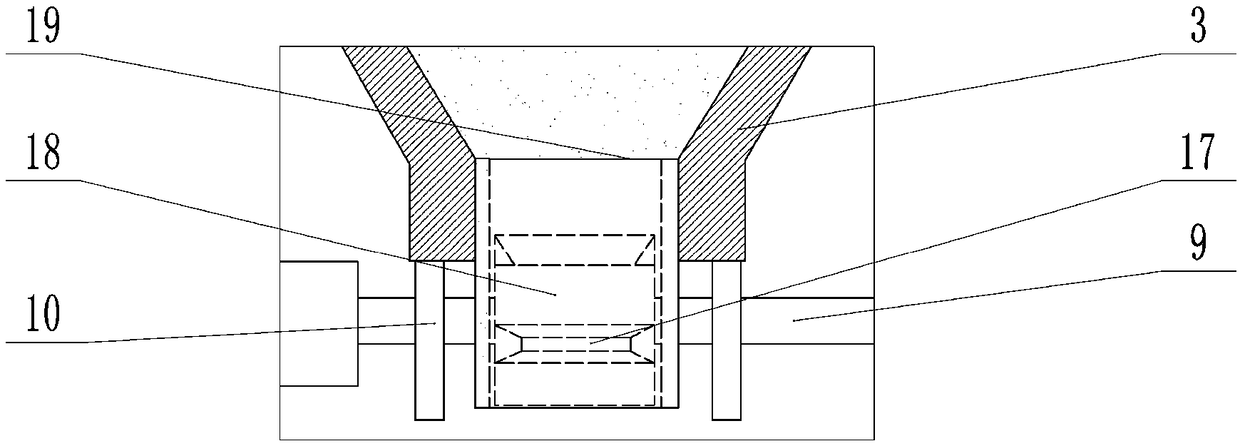

[0026] The embodiment is basically as attached figure 1 And attached figure 2 Shown: TDP moxibustion plaster powder filling production line, including: installation frame 1, the air guide box 4 is fixed on the installation frame 1, the bottom of the air guide box 4 is provided with a first air outlet, and the air guide box 4 is fixed with a motor 5, The motor 5 is provided with a fan for heat dissipation and a casing for air inlet and outlet. The motor 5 is also provided with an output shaft for outputting power. The fan is installed on the left side and the casing communicates with the air guide box 4. The motor 5 The output shaft of the motor 5 is installed horizontally to the right, the output shaft of the motor 5 is fixed with a rotating shaft 9, and the rotating shaft 9 is fixed with an eccentric wheel 10, a limiting cylinder 18, an eccentric wheel 10 and a rotating disk 11 from left to right; Axial circumferential direction is evenly provided with 4 limit grooves 17, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com