Drought-resistant and water-saving cultivation method for flue-cured tobacco

A cultivation method and flue-cured tobacco technology, applied in the field of flue-cured tobacco drought-resistant and water-saving cultivation, can solve the problems of high technical requirements for planters, difficult to popularize and popularize in a large area, complicated method and steps, etc., so as to restore soil aggregate structure, promote soil maturation, and optimize soil. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: A drought-resistant and water-saving cultivation method for flue-cured tobacco

[0039] Including the following steps:

[0040] (1) Spring irrigation is carried out on the tobacco planting land one month before transplanting, using sprinkler irrigation, and the irrigation volume is 18m 3 / 666.7m 2 .

[0041] (2) 13 days before transplanting, the tobacco field was deeply plowed and sun-dried, weeds were removed and leveled, without large soil lumps, and the depth of plowing reached 28cm.

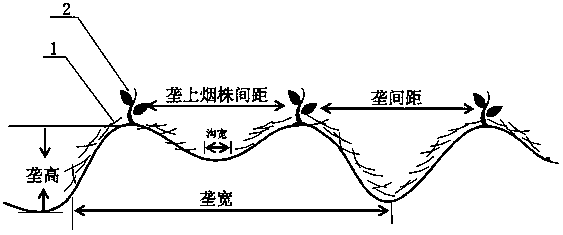

[0042] (3) if figure 1 As shown, adjust the distance between the blades of the ridging machine to 2.2m and then proceed to ridging. The height of the ridging is 28cm. After cultivating the soil, it reaches 30cm. The row spacing is 125cm, and the plant spacing is 58cm. Plant in wide and narrow rows, the crest of the wave is the tobacco planting row, double-row concave ridges, and plow a water collection ditch about 12cm deep in the middle of the ridges. The ridging m...

Embodiment 2

[0047] Embodiment 2: A drought-resistant and water-saving cultivation method for flue-cured tobacco

[0048] Including the following steps:

[0049] (1) One month before transplanting, spring irrigation was carried out on the tobacco planting land, using micro-spray irrigation, and the irrigation volume was 20m 3 / 666.7m 2 .

[0050] (2) Fifteen days before transplanting, the tobacco field was plowed and sun-dried, weeds were removed and leveled, without large soil lumps, and the depth of plowing reached 30cm.

[0051] (3) Adjust the distance between the blades of the ridging machine to 2.2m and then proceed to ridging. The height of the ridging is 30cm. After cultivating the soil, it reaches 35cm. The row spacing is 120cm, and the plant spacing is 60cm. Plant in wide and narrow rows, the crest of the wave is the tobacco planting row, double-row concave ridges, and plow a 15cm deep water collection ditch in the middle of the ridges. The ridging machine goes back and forth...

Embodiment 3

[0056] Embodiment 3: A drought-resistant and water-saving cultivation method for flue-cured tobacco

[0057] Including the following steps:

[0058] (1) Spring irrigation is carried out on the tobacco-planting land one month before transplanting, using micro-spray irrigation, and the irrigation volume is 22m 3 / 666.7m 2 .

[0059] (2) 18 days before transplanting, the tobacco field was deeply plowed and sun-dried, weeds were removed and leveled, without large soil blocks, and the depth of plowing reached 32cm.

[0060] (3) Adjust the distance between the blades of the ridging machine to 2.2m and then proceed to ridging. The height of the ridging is 32cm. After cultivating the soil, it will reach 32cm. The row spacing is 115cm, and the plant spacing is 62cm. Plant in wide and narrow rows, the crest of the wave is the tobacco planting row, double-row concave ridges, and plow a water collection ditch about 18cm deep in the middle of the ridges. The ridging machine goes back ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com