Duplex intertillage weeding machine

A weeder and compound technology, applied in the field of compound cultivator weeder, can solve the problems of serious removal rate of injured seedlings, difficult to eradicate weeds, etc., achieve the effect of reducing the number of field operations, improving soil and ecological environment, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

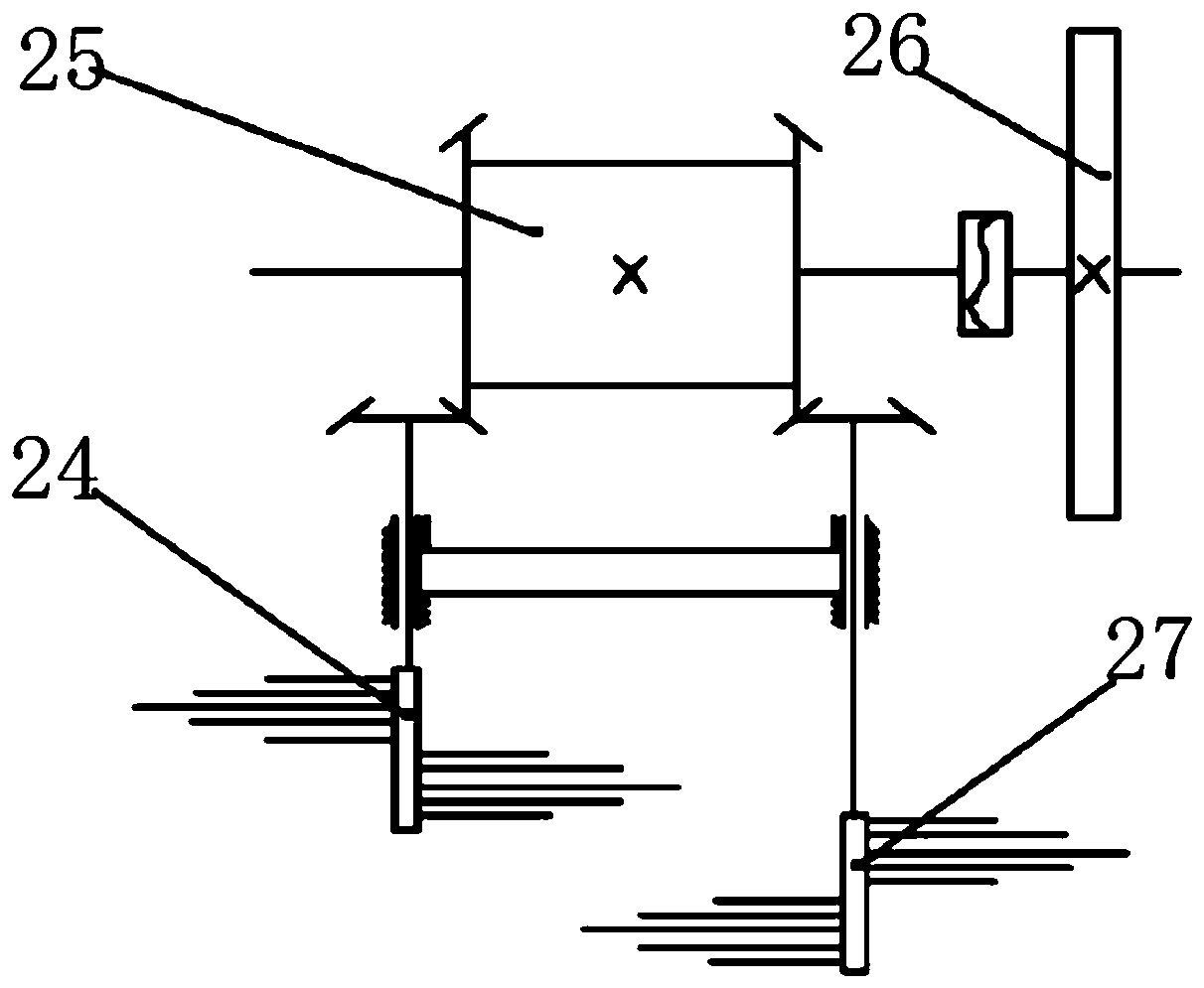

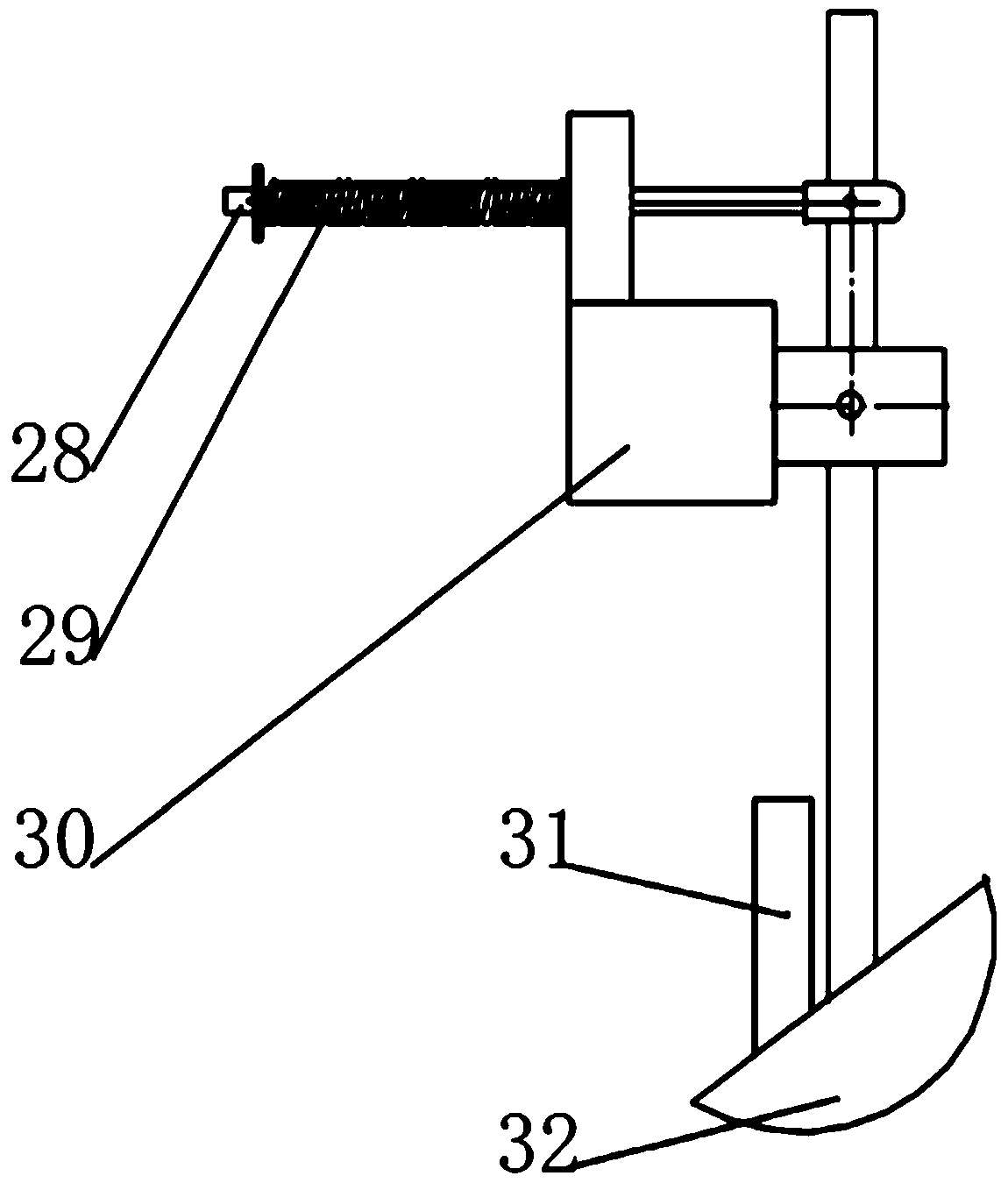

[0017] exist figure 1 Among them, including soil shovel, soil shovel bracket, profiling monomer, tension spring, four-link, profiling mechanism suspension frame, fertilizer box, fertilizer wheel, fertilizer box bracket, frame, intermediate shaft, ground wheel, ground Wheel bracket, fertilizer row opener, subsoiling shovel bank, subsoiling shovel handle, weeding single gear box, comb roller, boom, profiling wheel, comb teeth, adjusting screw, profiling theory bracket, among which during operation , the ground wheel (12) transmits the power to the intermediate shaft (11) through the chain, and then transmits the power to the fertilizer discharge shaft by the intermediate shaft to drive the fertilizer discharge shaft to fertilize. The fertilizer passes through the fertilizer spreading pipe to the side deep fertilization ditch opener (14) to realize deep fertilization on the side of the ridge; then, the intermediate shaft transmits it to the weeding device through gears with diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com