Square coiled battery pole piece as well as preparation method and square soft package battery thereof

A battery pole piece, winding technology, applied in electrode manufacturing, battery electrode, electrode current collector coating, etc., can solve the problems of reducing battery polarization, increasing battery polarization, etc., to reduce polarization effect, small polarization effect, improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

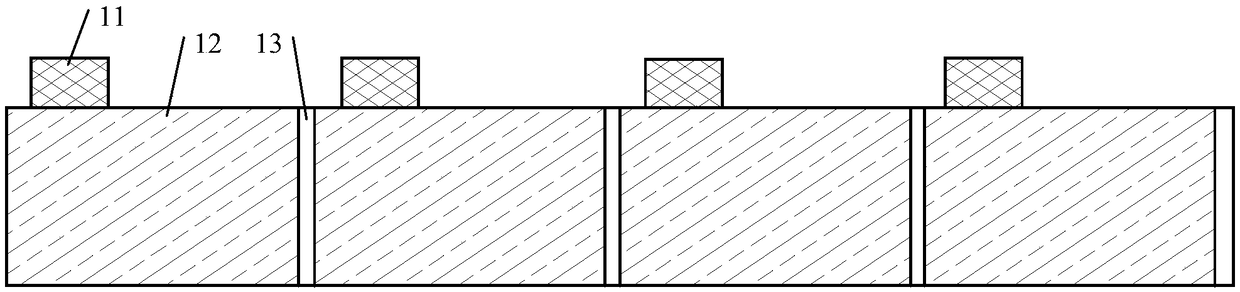

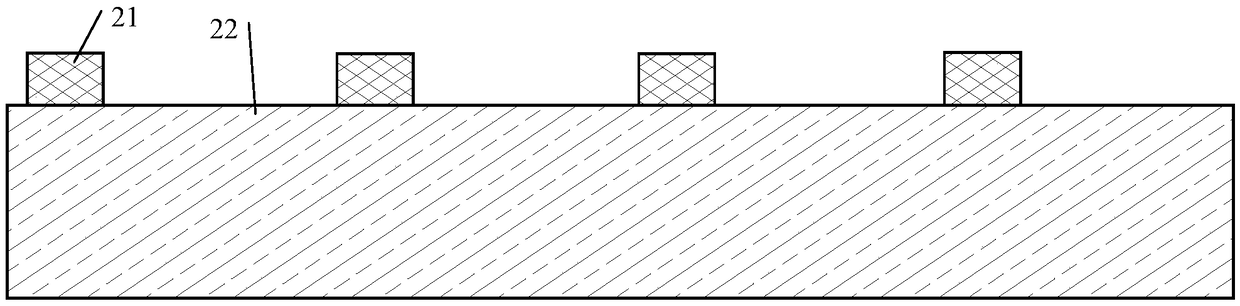

[0026] According to an embodiment of the present invention, a method for preparing a square wound battery pole piece is provided. The preparation method of the square wound battery pole piece may include: a coating step and a rolling and punching step. in:

[0027] Coating step: the battery slurry is intermittently coated on both sides of the current collector to form two or more slurry coating areas that are sequentially spaced along the length direction of the current collector (for example: the first slurry coating Zone 12), and there is a blank area (for example: blank zone 13) where the battery slurry is not coated at the end of each segment of the slurry coating zone.

[0028] For example: when the positive and negative electrode slurry of lithium ion battery is coated on the current collector, the intermittent coating method is adopted, that is, after each period of slurry is coated, a certain length of empty foil is left uncoated.

[0029] Wherein, the coating surfac...

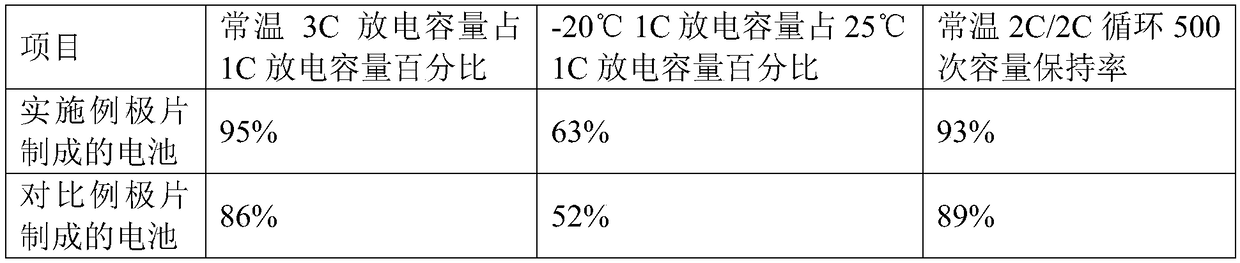

Embodiment

[0086] In one embodiment of the present invention, a kind of preparation method of square winding type pole piece for lithium ion battery is provided, the preparation method of square winding type pole piece for lithium ion battery may comprise the following steps:

[0087] Step 11. Take the positive electrode slurry to be coated and apply extrusion coating with a double-sided density of 150g / m 2 , the width of the aluminum foil is 130 mm, the thickness is 15 μm, and the coating width is 110 mm. One side in the lateral direction of the coating is reserved as a tab area without coating, and the width of the tab in the tab area is 20 mm.

[0088] Among them, at the beginning of coating (for example: using a coating machine for coating), the first section is left blank for 3mm after coating 80mm; the second section is left blank for 4mm after coating 82mm, and each additional section of , the coating length is increased by 2mm compared with the coating length of the previous sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com