Off-line device used for spent fuel transporting cask helium purification and cooling

A technology for transportation containers and spent fuel, which is applied in radioactive purification, portable protective containers, nuclear engineering, etc. It can solve the problems of not considering inner cavity helium purification and cooling devices, and achieve the effect of convenient transportation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

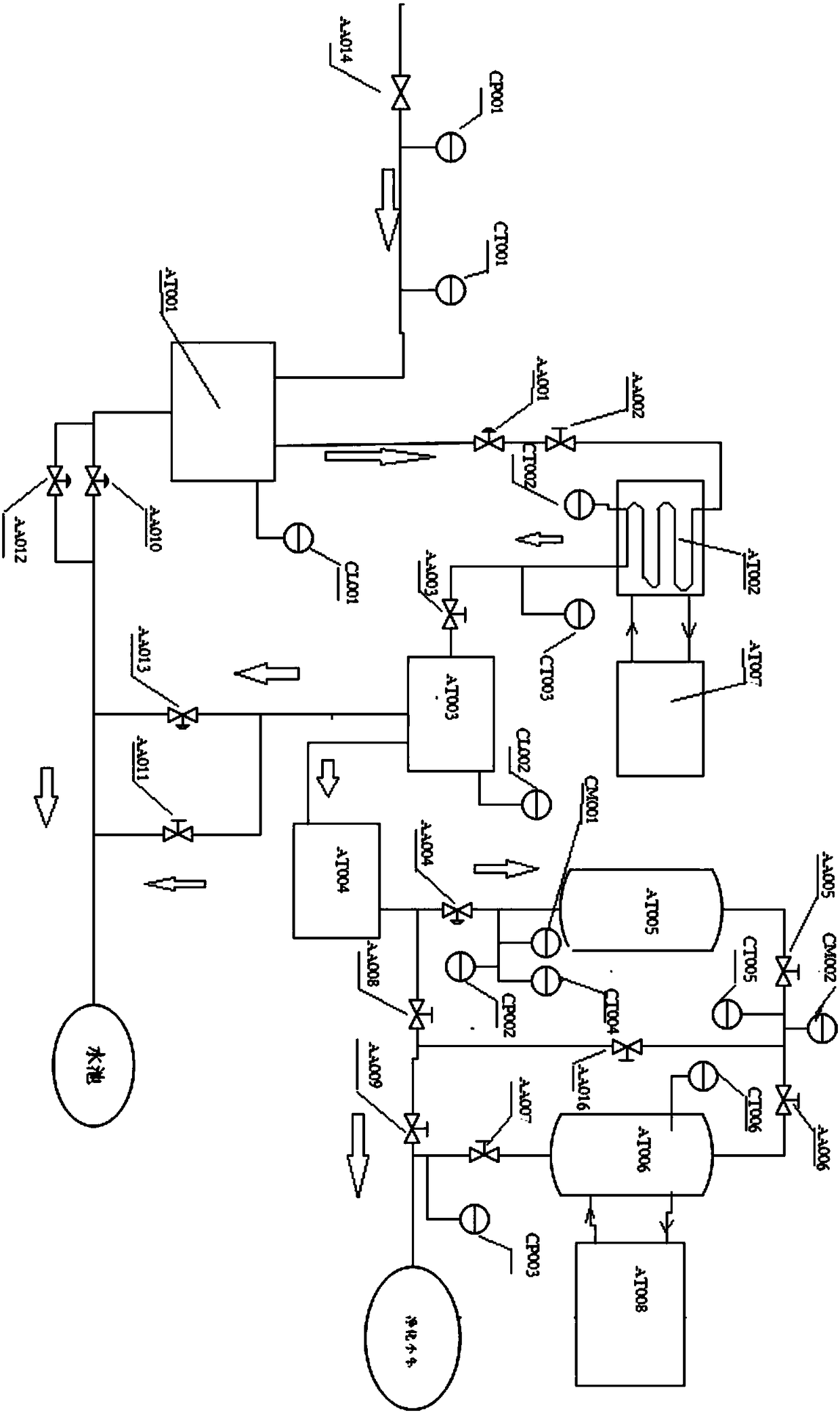

[0026] Valve AA014, pressure gauge CP001 and thermometer CT001 are arranged in series upstream of water level controller AT001, valve AA010 and valve AA012 are arranged in parallel downstream of water level controller AT001 and connected to the pool; valves AA001 and AA002 are located downstream of water level controller AT001 to control the gas pipe The downstream of it is the precooler AT002, the valve AA003 and the gas-water separator AT003 connected in turn. The thermometer CT002 is arranged in the precooler AT002, and the thermometer CT003 is arranged on the pipeline between the precooler AT002 and the valve AA003. The meter CL002 monitors the liquid level of the gas-water separator AT003; the refrigerator AT007 provides the cold source for the pre-cooler; the downstream of the gas-water separator AT003 arranges two pipelines in parallel, and is controlled by the valve AA011 and the valve AA013 respectively, and the separated water is discharged into the pool The downstrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com