Visualized oil-paper insulated electric heat combined aging device based on magnon stirring circulation

An aging device, oil-paper insulation technology, applied in the direction of testing dielectric strength, test ship construction, etc., can solve the problems of long detection cycle, long-lasting aging process of oil-paper insulation, affecting detection efficiency, etc., to speed up aging speed and improve detection accuracy. , the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

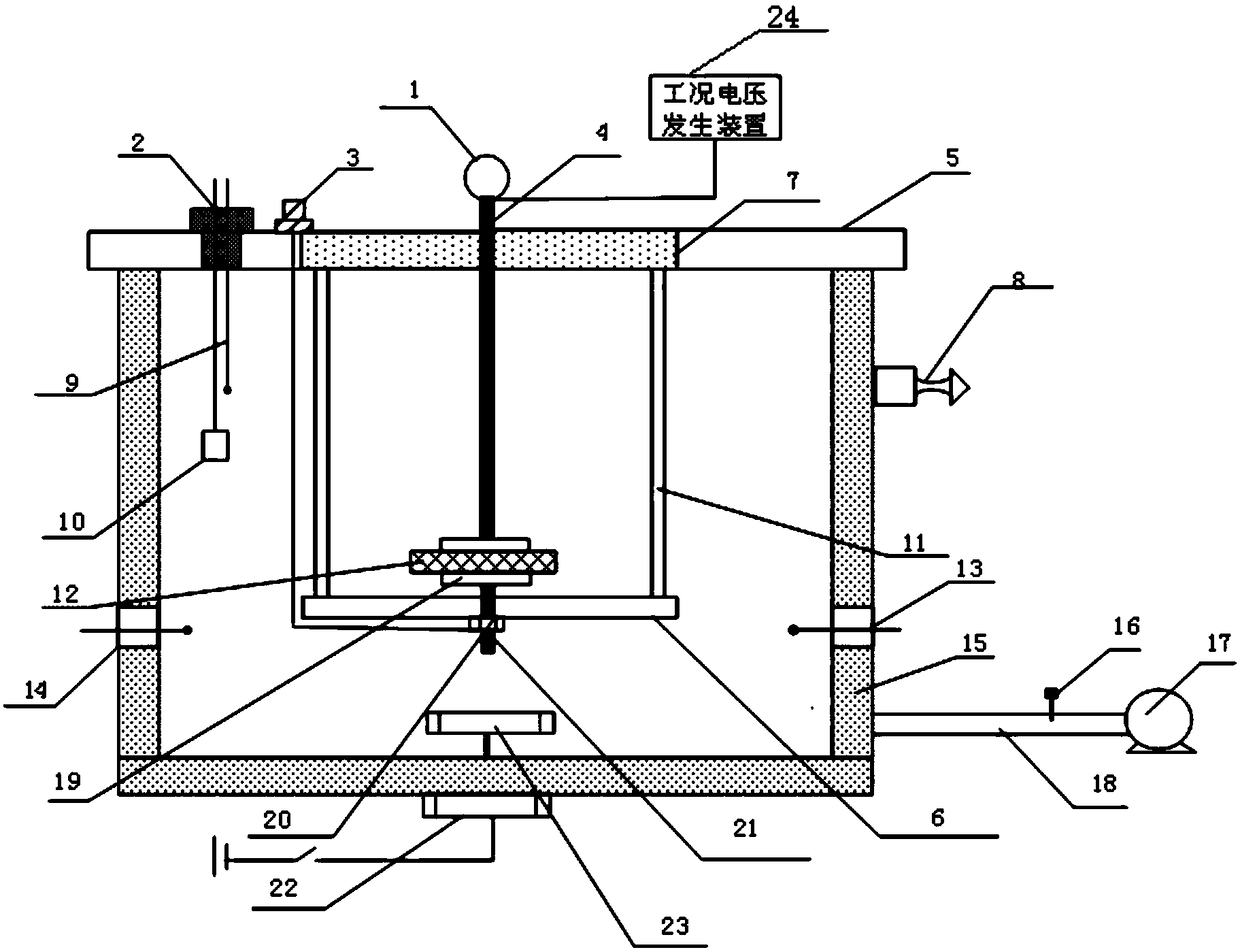

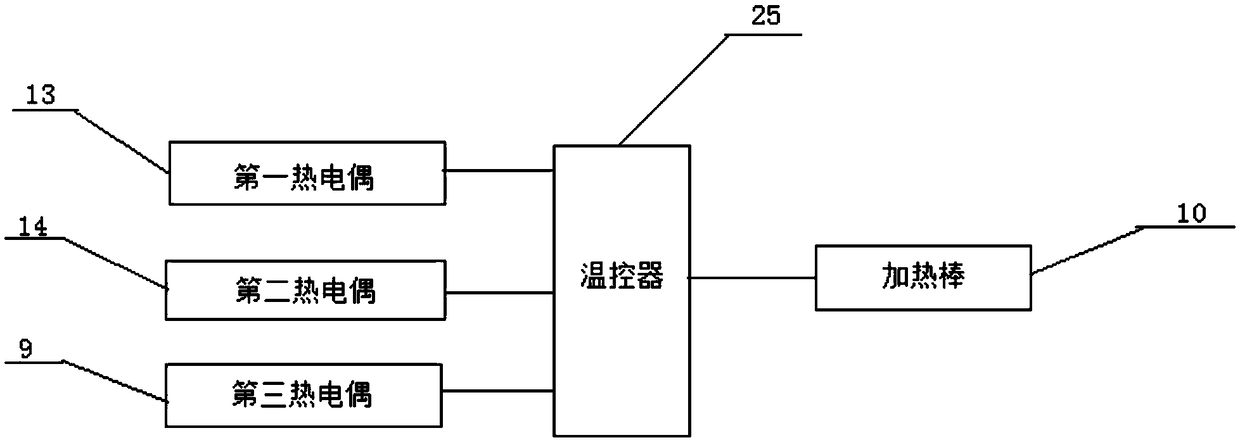

[0032] join figure 1 and figure 2 , the present application provides a visual oil-paper insulation electrothermal combined aging device based on the magnon stirring cycle, including a working condition voltage generating device 24, a box, an oil pipeline 18, an electric pump 17, an electrode aging device, a stirrer and a temperature control device;

[0033] The box body is a cavity 15 with an opening at the upper end surrounded by side walls and a bottom plate;

[0034] The agitator is installed on the base plate;

[0035] The opening of the box is provided with a cover plate 5, and the middle part of the cover plate 5 is provided with a tetrafluoroethylene layer 7;

[0036] The cover plate 5 is connected to the side wall by bolts;

[0037] One side wall of the box body is connected with the electric pump 17 through the oil pipeline 18, and one end of the oil pipeline extends into the box;

[0038] The electrode aging device includes a high-voltage electrode 4 and a low-v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com