Method for detecting maltopentaose by ultra-high performance liquid chromatography-mass spectrometry

An ultra-high-efficiency liquid phase, maltopentasaccharide technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high boiling point of carbohydrates, qualitative and quantitative interference, actual analysis errors, etc., to achieve weak ultraviolet color, Qualitative precision, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

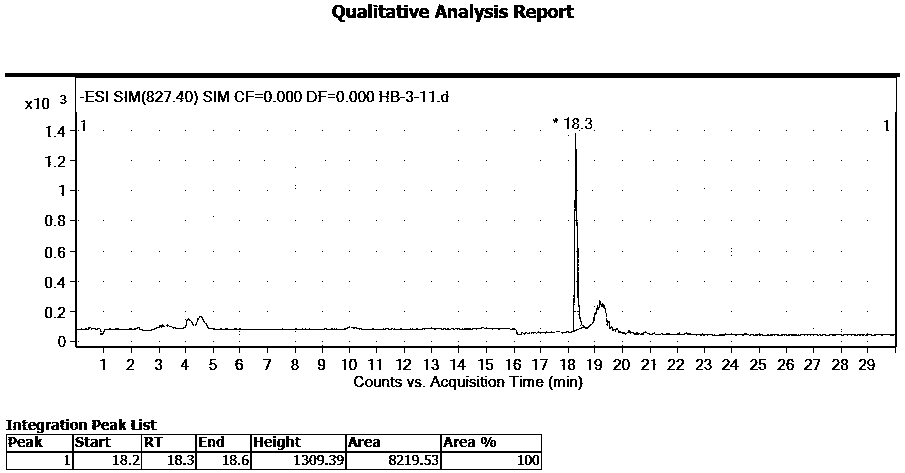

[0037] Chromatographic conditions: Agilent1290; Chromatographic column: Waters Xbridge BEH Amide (2.1x100mm), PartNo.: 186006091; Mobile phase: Acetonitrile-water gradient elution, 0-15min 87% acetonitrile, 15-20min 87% acetonitrile-15% acetonitrile, 20-30min 15% acetonitrile; flow rate: 0.4mL / min; column temperature: 40°C; injection volume: 0.5μL.

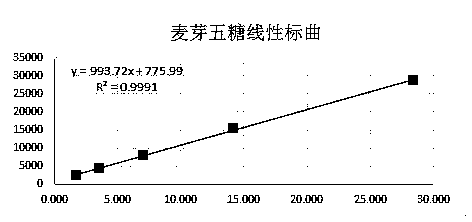

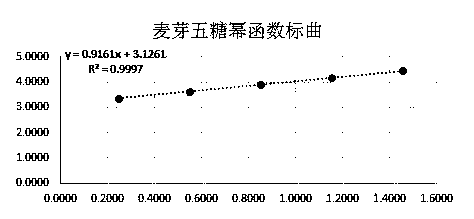

[0038] Mass spectrometry conditions: Agilent6460; ESI source, SIM mode, fragmentation voltage: 130v, sheath gas flow rate: 12L / min, capillary voltage: 4000v, extracted accurate mass number 827.4 ([M-H] - ), using the common logarithm of concentration and peak area for linear quantification.

[0039] Preparation of the test solution: Take 2.84mg of maltopentaose, accurately weighed, put in a 10mL volumetric flask, add water to dissolve and constant volume, shake well, accurately pipette 1mL, put in a 10mL volumetric flask, add water to dissolve and constant volume. Concentrate, shake well, and prepare maltopentaose mother liquor, ...

Embodiment 2

[0046] Chromatographic conditions: Agilent1290; Chromatographic column: Waters Xbridge BEH Amide (2.1x100mm), PartNo.: 186006091; Mobile phase: Acetonitrile-water gradient elution, 0-15min 87% acetonitrile, 15-20min 87% acetonitrile-15% acetonitrile, 20-30min 15% acetonitrile; flow rate: 0.4mL / min; column temperature: 40°C; injection volume: 0.5μL.

[0047] Mass spectrometry conditions: Agilent6460; ESI source, SIM mode, fragmentation voltage: 130v, sheath gas flow rate: 12 L / min, capillary voltage: 4000v, extracted accurate mass number 827.4 ([M-H] - ), using the common logarithm of concentration and peak area for linear quantification.

[0048] Preparation of the test solution: take 2.84 mg of maltopentaose, accurately weigh it, put it in a 10ml volumetric flask, add water to dissolve it and constant volume, shake well, pipette 1ml precisely, put it in a 10ml volumetric flask, add water to dissolve it and constant volume. Mix and shake well to prepare maltopentaose mother l...

Embodiment 3

[0054] Chromatographic conditions: Agilent1290; Chromatographic column: Waters Xbridge BEH Amide (2.1x100mm), PartNo.: 186006091; Mobile phase: Acetonitrile-water gradient elution, 0-15min 87% acetonitrile, 15-20min 87% acetonitrile-15% acetonitrile, 20-30min 15% acetonitrile; flow rate: 0.4mL / min; column temperature: 40°C; injection volume: 0.5μL.

[0055] Mass spectrometry conditions: Agilent6460; ESI source, SIM mode, fragmentation voltage: 130v, sheath gas flow rate: 12L / min, capillary voltage: 4000v, extracted accurate mass number 827.4 ([M-H] - ), using the common logarithm of concentration and peak area for linear quantification.

[0056] Preparation of the test solution: take 2.84 mg of maltopentaose, accurately weigh it, put it in a 10ml volumetric flask, add water to dissolve it and constant volume, shake well, pipette 1ml precisely, put it in a 10ml volumetric flask, add water to dissolve it and constant volume. Mix and shake well to prepare maltopentaose mother li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com