Self-adhesive waterproof roll with electromagnetic shielding function and preparation method of self-adhesive waterproof roll with electromagnetic shielding function

A self-adhesive waterproof membrane and electromagnetic shielding technology, which is applied in the direction of film/sheet adhesives, adhesives, rosin adhesives, etc., can solve the problems of affecting electromagnetic shielding effectiveness, reducing shielding effectiveness, and difficulty in meeting environmental protection performance. Needs and other issues, to achieve excellent electromagnetic shielding function, improve peeling adhesive strength, increase the effect of electromagnetic shielding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

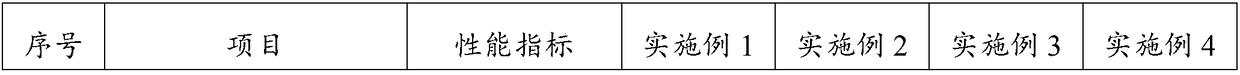

Examples

Embodiment 1

[0041] A kind of self-adhesive waterproof roll material with electromagnetic shielding function, its preparation process is as follows:

[0042] (1) Preparation of butyl pressure-sensitive self-adhesive

[0043] 1) Put 10 parts by weight of butyl rubber, 5 parts of C5 petroleum resin, 0.5 parts of chemical coupling agent, 1 part of antioxidant, 1 part of light stabilizer and 10 parts of nano conductive filler into a vacuum kneader In the process, heat up first, then stir for the first time, vacuumize, the stirring temperature is 100°C, the vacuum condition is 0.09-0.094MPa, the stirring time is 0.5h, and the mixture A is obtained;

[0044] 2) To the mixture A obtained in step 1), add 10 parts by weight of plasticizer, 1 part of nano-sized zinc oxide and 10 parts by weight of reinforcing agent, vacuumize, and carry out the second Stir, the stirring temperature is 100°C, the vacuum condition is 0.09-0.094MPa, and the stirring time is 0.5h, to obtain butyl pressure-sensitive sel...

Embodiment 2

[0051] A kind of self-adhesive waterproof roll material with electromagnetic shielding function, its preparation process is as follows:

[0052] (1) Preparation of butyl pressure-sensitive self-adhesive

[0053] 1) Put 20 parts by weight of butyl rubber, 30 parts of tackifier, 1 part of chemical coupling agent, 5 parts of antioxidant, 1 part of light stabilizer and 30 parts of nano conductive filler into a vacuum kneader In the process, heat up first, then stir for the first time, vacuumize, the stirring temperature is 140°C, the vacuum condition is 0.09-0.094MPa, the stirring time is 0.8h, and the mixture A is obtained;

[0054] 2) To the mixture A obtained in step 1), add 30 parts by weight of a plasticizer, 3 parts by weight of nano-sized zinc oxide and a reinforcing agent of 30 parts by weight, vacuumize, and perform the second Stirring, the stirring temperature is 140°C, the vacuum condition is 0.09-0.094MPa, and the stirring time is 0.8h, to obtain butyl pressure-sensitiv...

Embodiment 3

[0061] A kind of self-adhesive waterproof roll material with electromagnetic shielding function, its preparation process is as follows:

[0062] (1) Preparation of butyl pressure-sensitive self-adhesive

[0063] 1) Put 30 parts by weight of butyl rubber, 40 parts of tackifier, 3 parts of chemical coupling agent, 5 parts of antioxidant, 3 parts of light stabilizer and 35 parts of nano conductive filler into a vacuum kneader In the process, heat up first, then stir for the first time, vacuumize, the stirring temperature is 180°C, the vacuum condition is 0.09-0.094MPa, the stirring time is 1h, and the mixture A is obtained;

[0064] 2) To the mixture A obtained in step 1), add 50 parts by weight of plasticizer, 5 parts by weight of nano-sized zinc oxide and 50 parts by weight of reinforcing agent, vacuumize, and carry out the second Stir, the stirring temperature is 180°C, the vacuum condition is 0.09-0.094MPa, the stirring time is 1h, and the material is discharged to obtain bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com