Assembling method for electromagnetic shielding heat-conducting adhesive tape

A technology of electromagnetic shielding and assembly method, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of adding tape, affecting normal use, occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

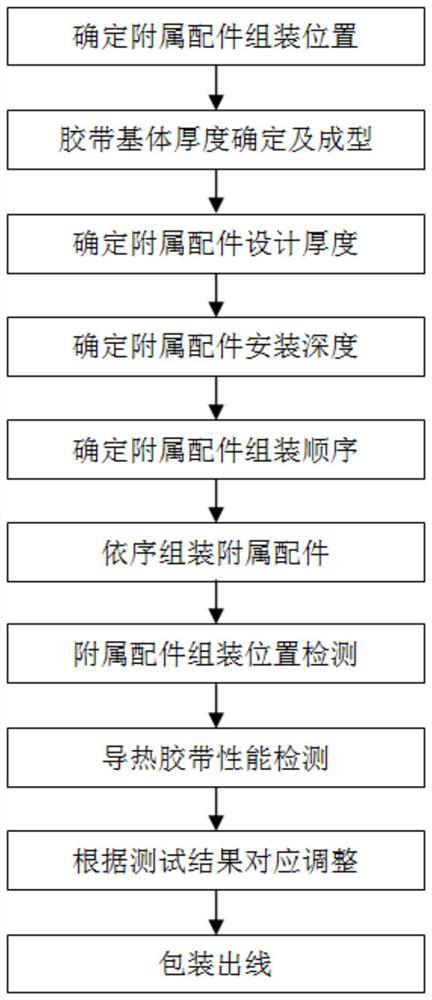

[0032] A method for assembling an electromagnetic shielding thermally conductive adhesive tape, characterized in that it comprises the following steps:

[0033] 1) Determine the corresponding assembly position of each accessory part on the tape base according to the preset first priority;

[0034] 2) Determine the thickness of the tape base at the position of each accessory on the tape base, and shape the tape base to the corresponding thickness at the position of each accessory;

[0035] 3) Determine the design thickness of each accessory part on the tape base according to the thickness of each position on the tape base before and after forming;

[0036] 4) Determine the installation depth of each accessory accessory corresponding to the assembly position on the tape substrate;

[0037] 5) Determine the assembly sequence of the accessories on the tape base according to the preset second priority;

[0038] 6) According to the assembly sequence determined in step 5), assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com