Double vortex electric field assisted ultrafast laser machining system and machining method thereof

An electric field-assisted, ultra-fast laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of reducing impact, reducing energy loss, and wide material universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The system and method proposed by the present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

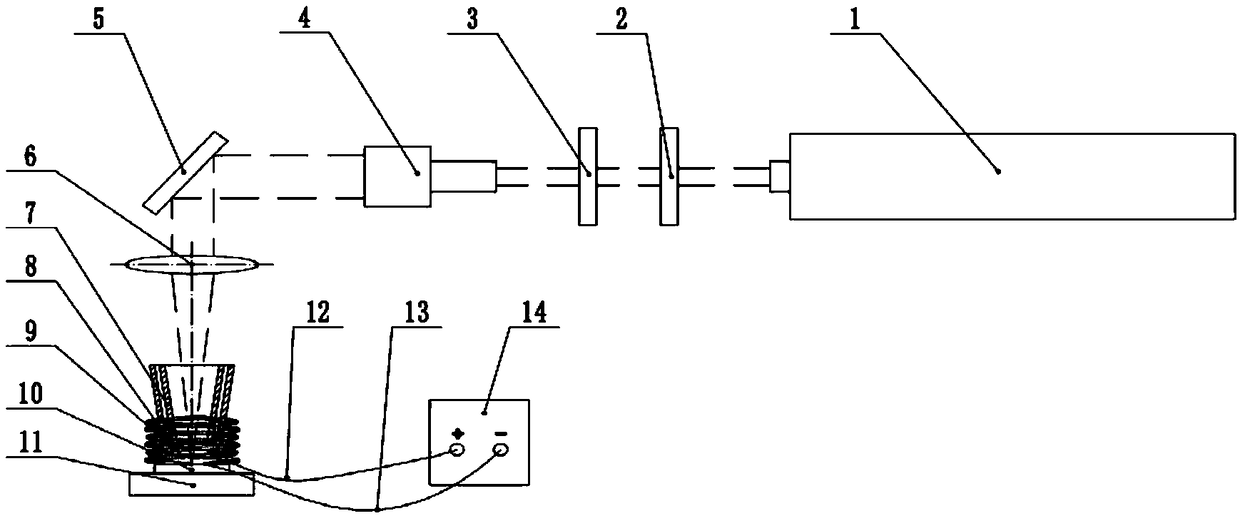

[0023] Such as figure 1 As shown, the double vortex electric field assisted ultrafast laser processing system provided by the present invention includes an ultrafast laser 1, a polarizer 2, a half wave plate 3, a beam amplifier 4, a mirror 5, a focusing mirror 6, a coaxial Suction device 7, positive spiral electrode 8, negative spiral electrode 9, workpiece 10, five-axis displacement platform 11, positive lead wire 12, negative lead lead 13, power supply 14, wherein, power supply 14 is connected with positive spiral electrode 8 through positive lead wire 12, The negative wire 13 is connected to the negative spiral electrode 9, the workpiece 10 is clamped on the five-ax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com