A kind of renewable dry flue gas desulfurizer and its preparation method and application

A dry-process flue gas desulfurization and desulfurization agent technology, applied in the field of flue gas desulfurization purification, can solve the problems of low utilization rate of calcium oxide, poor regeneration performance of desulfurization agent, and low desulfurization efficiency, so as to save dust removal steps and low additive content , the effect of high sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

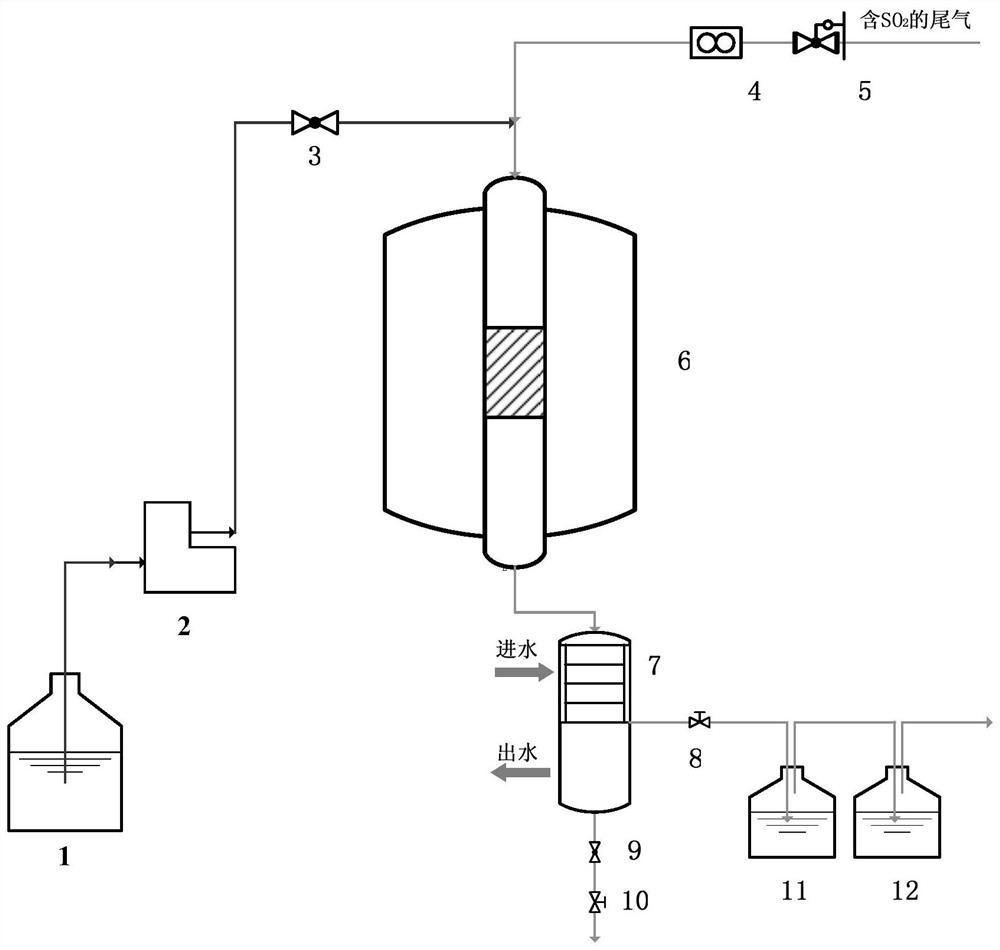

Image

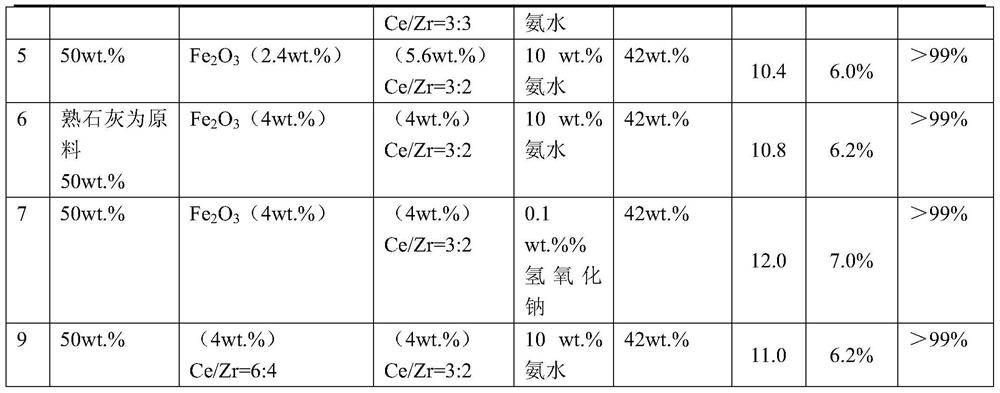

Examples

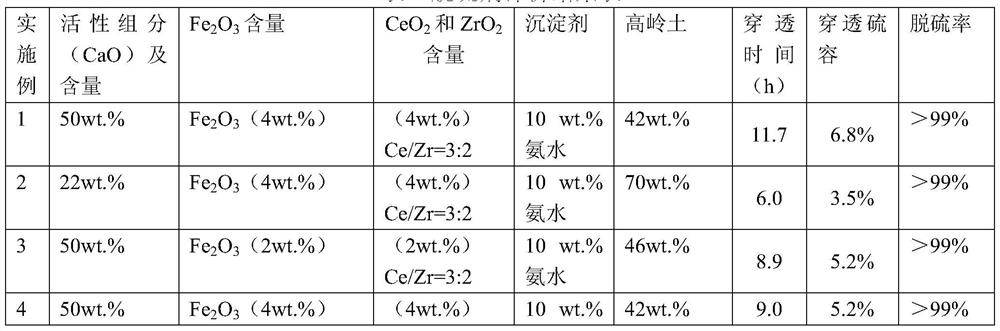

Embodiment 1

[0045] Preparation of desulfurizer 1.

[0046] Active components and content: quicklime is used as raw material, CaO (50wt.%);

[0047] Additives and content: Fe 2 o 3 (4wt.%), CeO 2 and ZrO 2 (4wt.%, the molar ratio of Ce and Zr is 3:2);

[0048] Carrier and content: Kaolin (42wt.%).

[0049] Concrete preparation method is:

[0050] (1) Take by weighing 20g ferric nitrate nonahydrate, 6.8g cerium nitrate hexahydrate and 4.5g zirconium nitrate pentahydrate and dissolve them in 200ml deionized water, stir until completely dissolved at 40°C, use 10wt.% ammonia solution to adjust pH = Stop at 10 o'clock. Aged at 40°C for 4h, then filtered. After filtration, it was dried at 110°C for later use to obtain the additive composite oxide.

[0051] (2) After weighing 50g of quicklime, 42g of kaolin and the auxiliary composite oxide, carry out dry ball milling mixing, the ball milling speed is 200rpm / min, the particle size of the powder after ball milling is 150-200 mesh, add wat...

Embodiment 2

[0054] Preparation of desulfurizer 2.

[0055] Active components and content: quicklime is used as raw material, CaO (22wt.%);

[0056] Additives and content: Fe 2 o 3 (4wt.%), CeO 2 and ZrO 2 (4wt.%, the molar ratio of Ce and Zr is 3:2);

[0057] Carrier and content: kaolin (70wt.%).

[0058] Concrete preparation method is:

[0059] (1) Take by weighing 20g ferric nitrate nonahydrate, 6.8g cerium nitrate hexahydrate and 4.5g zirconium nitrate pentahydrate and dissolve them in 200ml deionized water, stir until completely dissolved at 40°C, use 10wt.% ammonia solution to adjust pH = Stop at 10 o'clock. Aged at 40°C for 4h, then filtered. After filtration, it was dried at 110°C for later use to obtain the additive composite oxide.

[0060] (2) After weighing 22g of quicklime, 70g of kaolin and the auxiliary composite oxide, carry out dry ball milling mixing, the ball milling speed is 200rpm / min, the particle size of the powder after ball milling is 150-200 mesh, add wat...

Embodiment 3

[0063] Preparation of desulfurizer 3.

[0064] Active components and content: quicklime is used as raw material, CaO (50wt.%);

[0065] Additives and content: Fe 2 o 3 (2wt.%), CeO 2 and ZrO 2 (2wt.%, the molar ratio of Ce and Zr is 3:2);

[0066] Carrier and content: Kaolin (46wt.%).

[0067] Concrete preparation method is:

[0068] (1) Take by weighing 10g ferric nitrate nonahydrate, 3.4g cerium nitrate hexahydrate and 2.3g zirconium nitrate pentahydrate and dissolve them in 200ml deionized water, stir until completely dissolved at 40°C, use 10wt.% ammonia solution to adjust pH = Stop at 10 o'clock. Aged at 40°C for 4h, then filtered. After filtration, it was dried at 110°C for later use to obtain the additive composite oxide.

[0069] (2) After weighing 50g of quicklime, 46g of kaolin and the auxiliary composite oxide, carry out dry ball milling mixing, the ball milling speed is 200rpm / min, the particle size of the powder after ball milling is 150-200 mesh, add wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com