Coke oven flue desulfurization, denitrification and purification device

A desulfurization, denitrification and purification device technology, which is applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as inability to desulfurize and denitrify flue gas, affect flue gas purification efficiency, and insufficient stirring of solutions, etc., to achieve The effect of improving purification efficiency and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

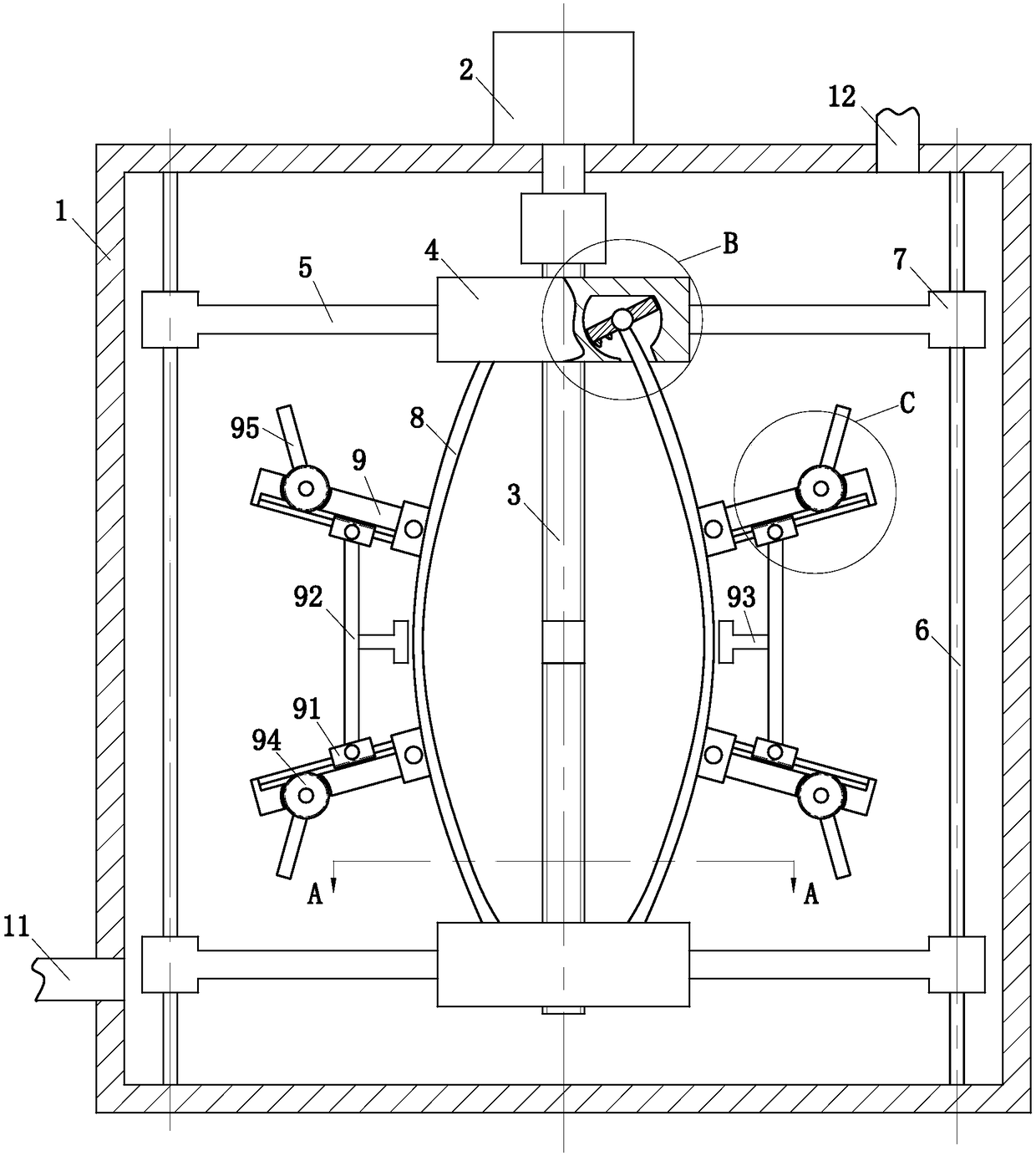

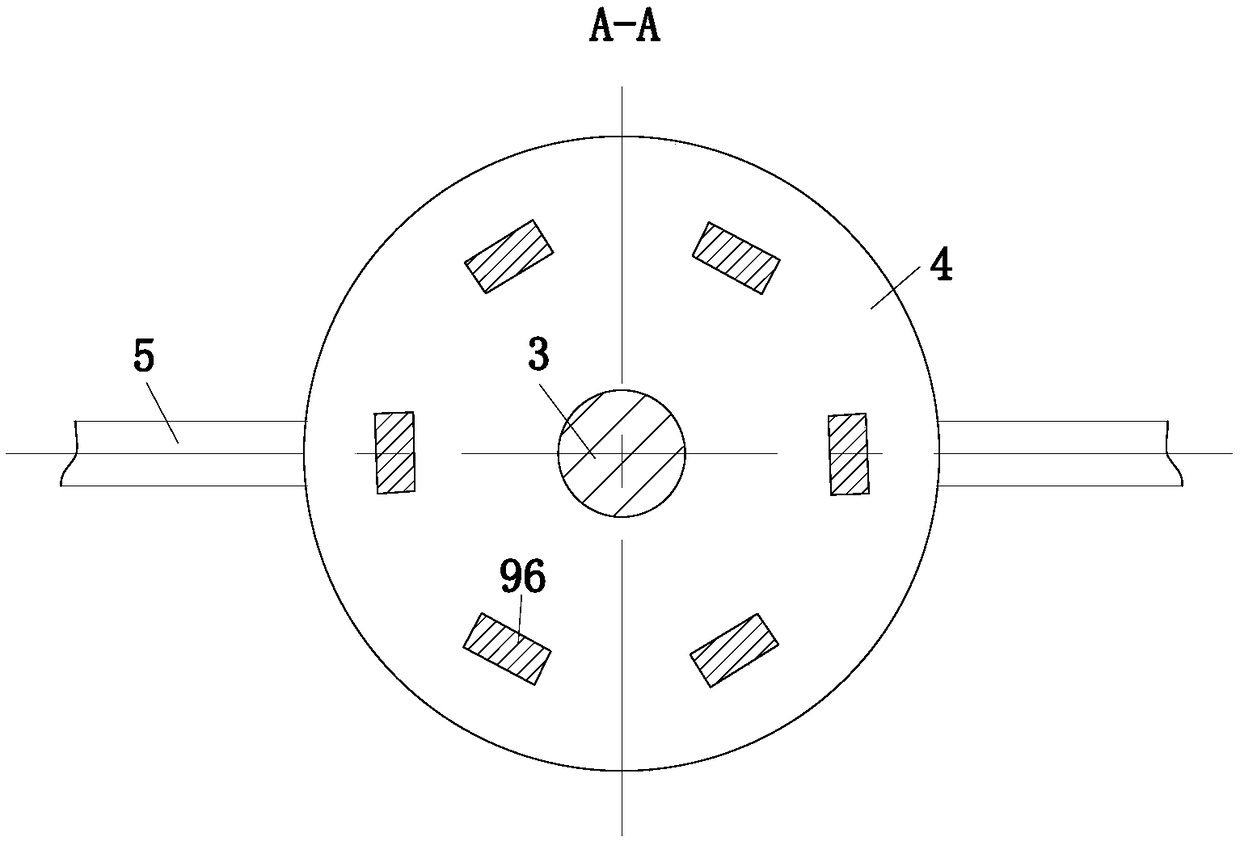

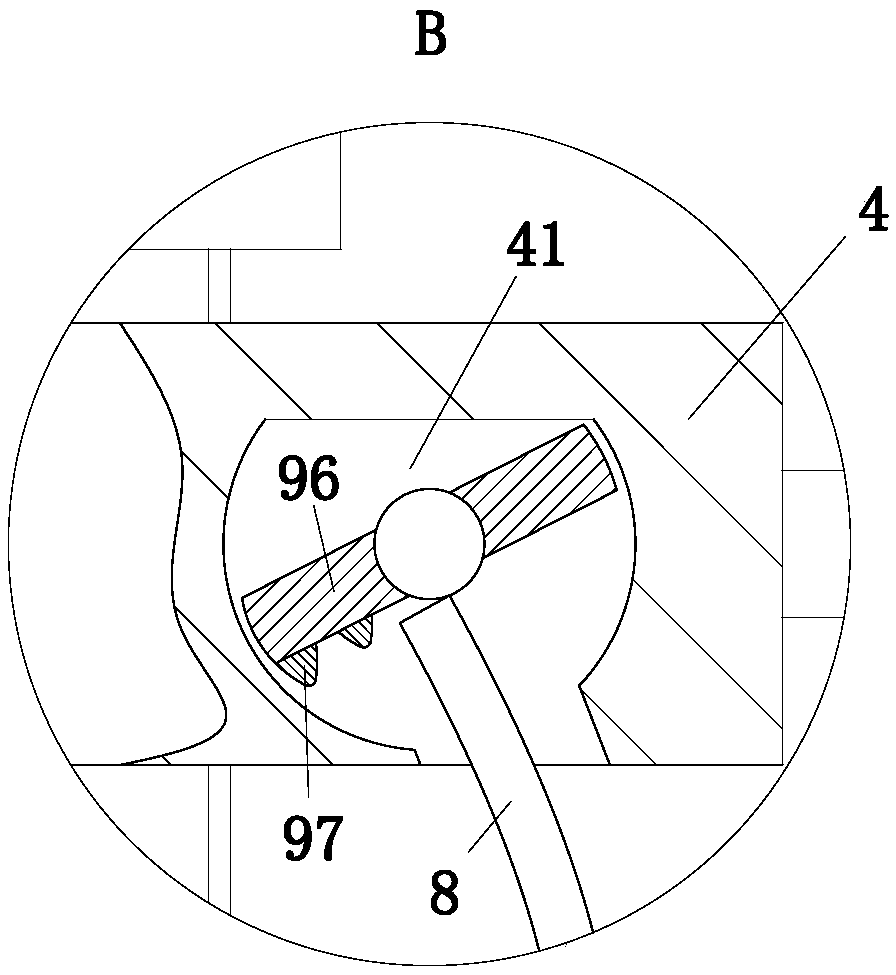

[0023] As an embodiment of the present invention, a sliding block 91 is provided on one side of the movable plate 9; the two sliding blocks 91 on the two vertical movable plates 9 are connected by a connecting rod 92, and the middle part of the connecting rod 92 is arranged There are T-shaped plates 93 . When the supporting elastic piece 8 is deformed by being squeezed by the rotating ring 4, the supporting elastic piece 8 first contacts the T-shaped plate 93, and as the rotating ring 4 continues to move closer, the supporting elastic piece 8 pushes the T-shaped plate 93 to move the connecting rod 92, The sliding block 91 hinged with the connecting rod 92 slides, the farther the sliding block 91 slides on one side of the movable plate 9, the larger the swing range of the movable plate 9 is, and the driving motor 2 controls the moving ring 4 to move closer and apart, so that the sliding The block 91 slides back and forth, so that the movable plate 9 can fully stir the solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com