Inductive infusion support

A technology of infusion stand and induction block, which is applied in the field of induction infusion stand, can solve the problems of inconvenient height adjustment, inconvenient use, inconvenient movement, etc., and achieve the effects of improving work efficiency, avoiding confusion, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The following is attached Figure 1-7 The present invention is described in further detail.

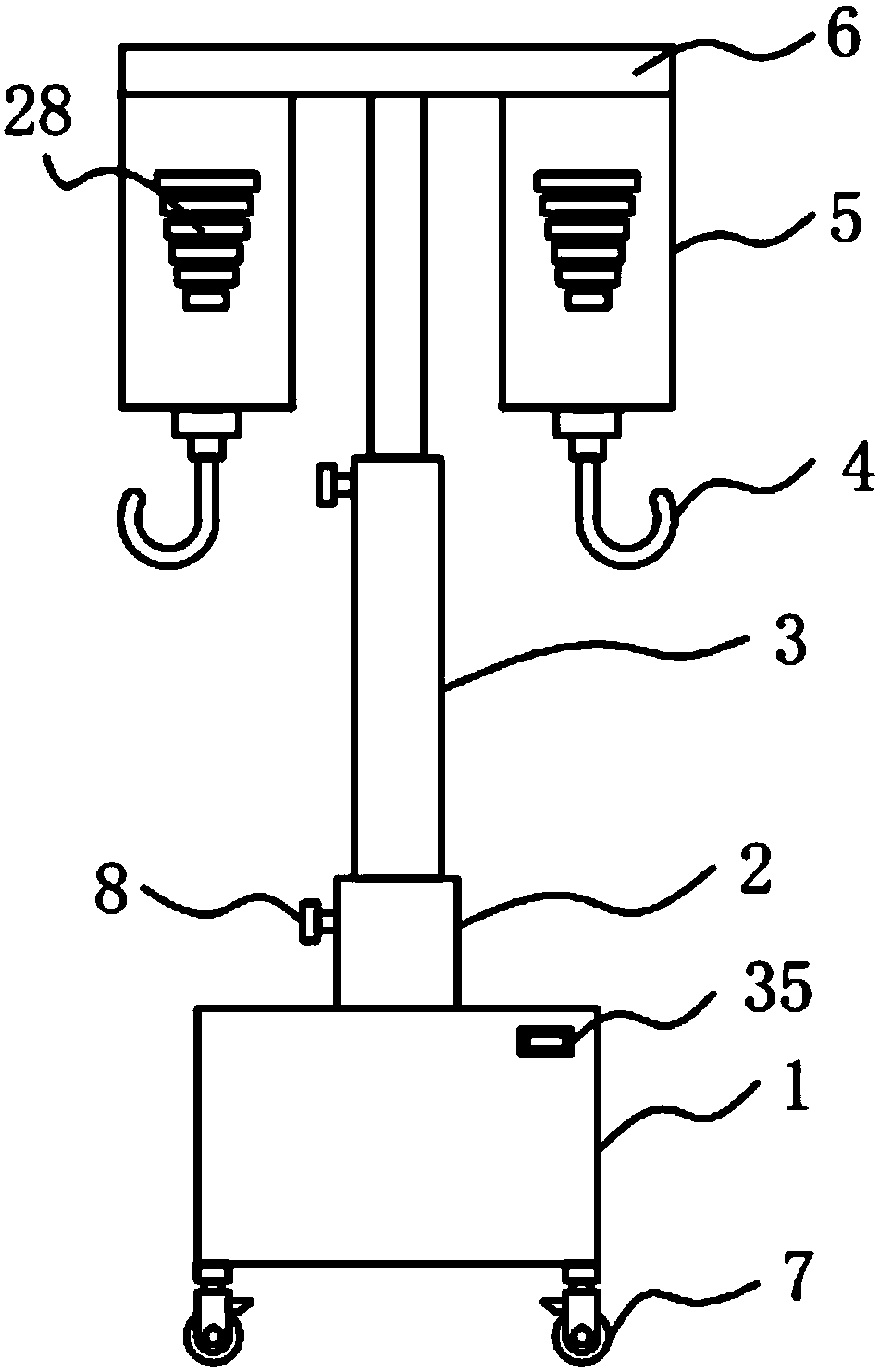

[0048] An induction infusion stand, such as Figure 1-7 As shown, it includes a base 1 and a hook 4. The upper part of the base 1 is equipped with a telescopic rod 3 through a fixed sleeve 2, and the bottom of the base 1 is provided with a universal wheel 7, and the telescopic end of the telescopic rod 3 is fixed. A crossbar 6 is installed, and induction devices 5 are symmetrically installed at the bottom of both ends of the crossbar 6;

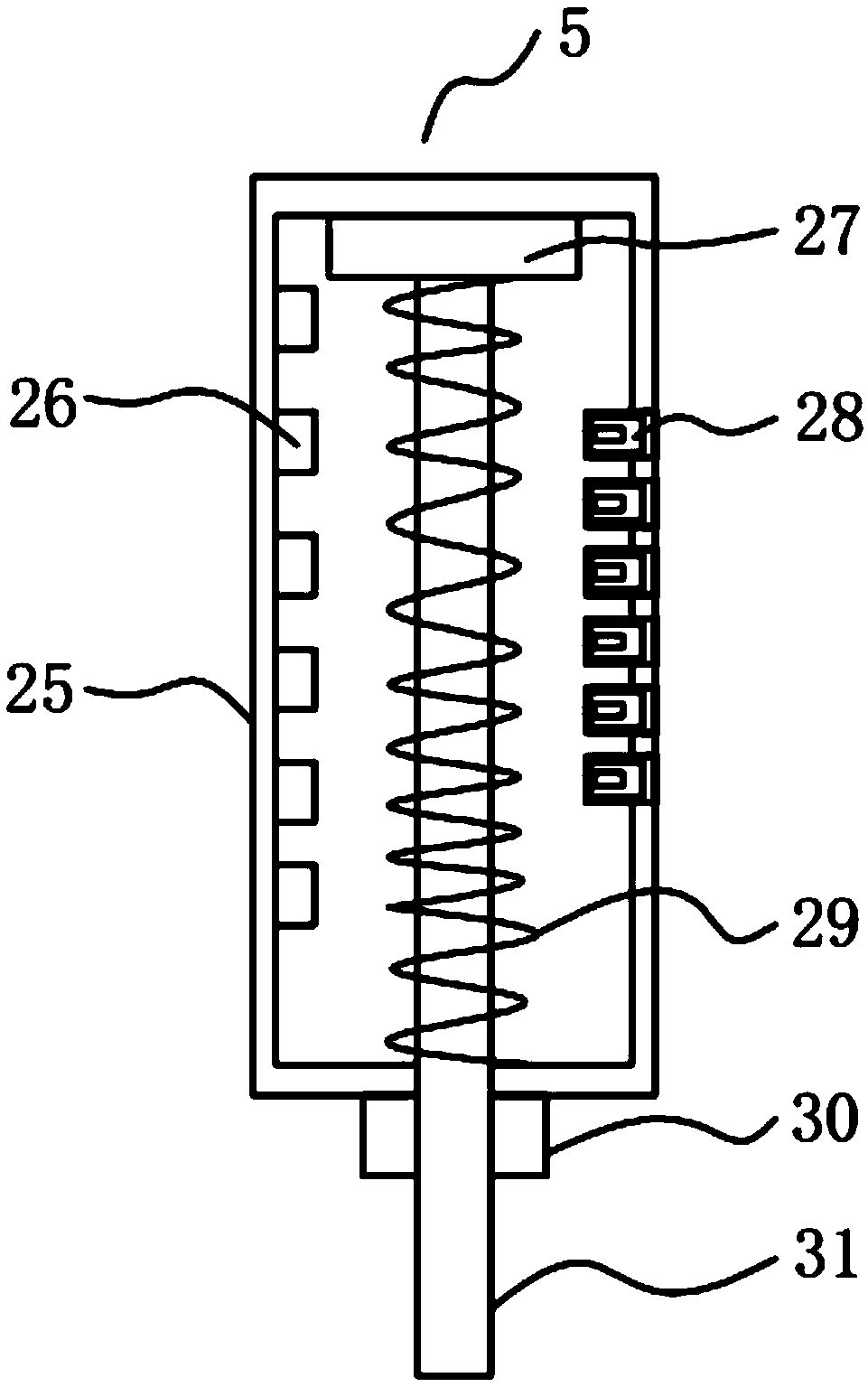

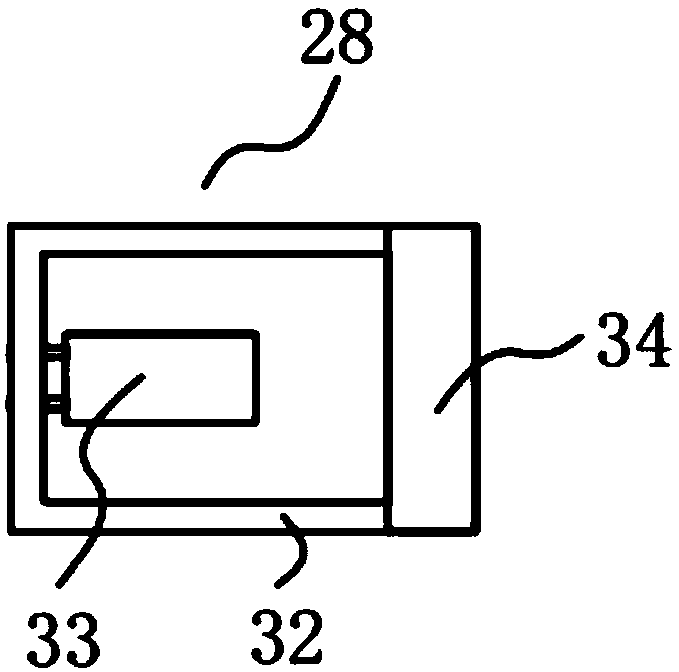

[0049] The induction device 5 includes a square housing 25, an induction block 27, a display unit 28, a pole 31, a first spring 29 and a proximity switch 26, and the induction block 27 is movably arranged inside the square housing 25, and the induction block 27 is fixedly installed on the upper end of the vertical rod 31, and the vertical rod 31 is movably arranged inside the square housing 25, and the bottom end of the vertical rod 31 runs ...

Embodiment 2

[0061] The difference from Example 1 is that the outside of the hook 4 is also covered with an anti-slip sleeve, and the anti-slip sleeve is prepared by the following method:

[0062] Take the following raw materials and weigh them by weight: 70 parts of natural rubber, 20 parts of halogenated butyl rubber, 30 parts of methanol, 4 parts of silane coupling agent, 10 parts of titanium dioxide powder, 7 parts of epoxy resin powder, and 2 parts of p-phenylenediamine , 3 parts of diethylthiourea, 6 parts of paraffin oil;

[0063] S1. Add the weighed natural rubber, halogenated butyl rubber, methanol, epoxy resin powder, titanium dioxide powder and silane coupling agent into the internal mixer for internal mixing. The temperature of the internal mixer is set to 130°C and the speed is set is 600r / min, and the banburying time is 20min, and the banburying material is obtained;

[0064] S2. Add the banburying material prepared in step S1, p-phenylenediamine, diethylthiourea, and paraff...

Embodiment 3

[0070] The difference from Example 2 lies in the preparation of the anti-slip sleeve. The specific preparation method is as follows: take the following raw materials and weigh them in parts by weight: 80 parts of natural rubber, 25 parts of halogenated butyl rubber, 40 parts of methanol, 5 parts of silane coupling agent 11 parts of titanium dioxide powder, 8 parts of epoxy resin powder, 3 parts of p-phenylenediamine, 4 parts of diethylthiourea, 7 parts of paraffin oil;

[0071] S1. Add the weighed natural rubber, halogenated butyl rubber, methanol, epoxy resin powder, titanium dioxide powder and silane coupling agent into the internal mixer for internal mixing. The temperature of the internal mixer is set to 140°C and the speed is set It is 700r / min, and the banburying time is 25min, and the banburying material is obtained;

[0072] S2. Add the banburying material prepared in step S1, p-phenylenediamine, diethylthiourea, and paraffin oil into the mixer for stirring and mixing....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com