Binning device used after tobacco leaf sorting

A technology for separating warehouses and tobacco leaves, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems of long cylinder strokes and loud noises, and achieve the effects of improving speed and efficiency, satisfying frequent actions, and reducing the action stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

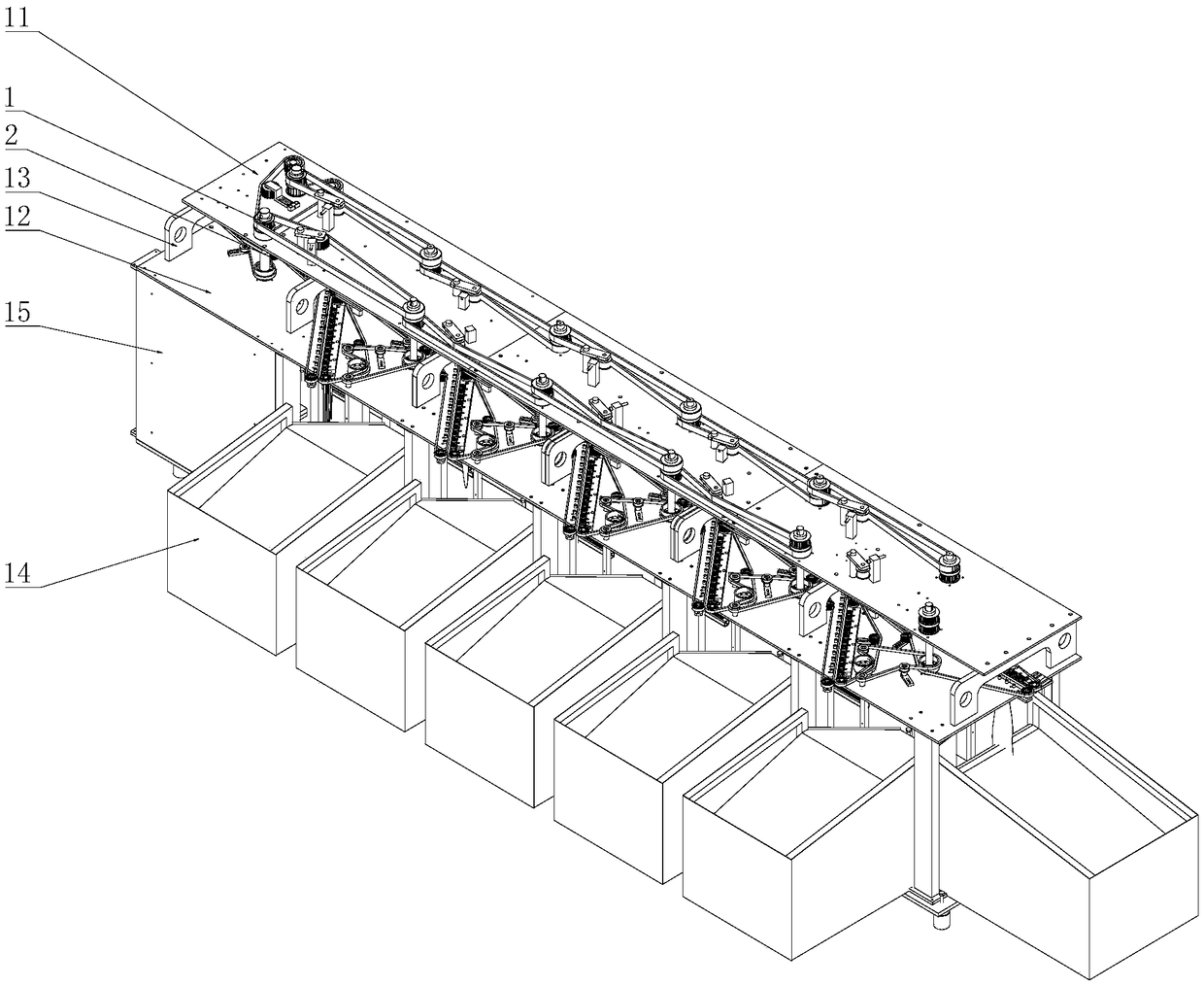

[0020] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0021] Figure 1 to Figure 4 The shown binning device for sorting tobacco leaves consists of a power mechanism and five binning stations, each binning station includes a transmission mechanism, a conveying mechanism and a binning mechanism, and the power mechanism is driven by a belt The transmission mechanism moves, and the transmission mechanism and the conveying mechanism are in a linkage relationship. The binning mechanism performs binning processing on the tobacco leaves transported by the conveying mechanism. The power mechanism is installed on the frame 15, including the motor and the driving wheel 1, and the motor is installed on the frame 15. Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com