Fault diagnosis method for annular air valve of reciprocating compressor

A fault diagnosis and compressor technology, applied in the field of compressors to achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

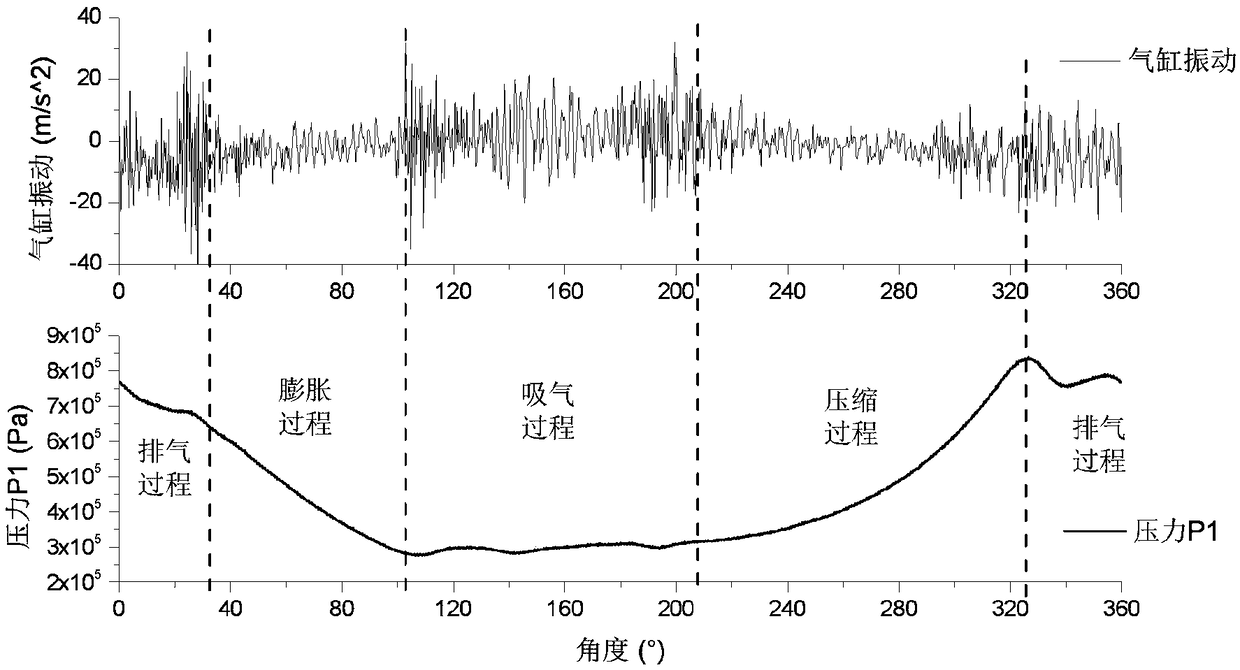

[0033] The reciprocating compressor selected in this embodiment is a DW-8 / 10 two-stage air compressor manufactured by Sichuan Jinxing Compressor Co., Ltd., with a volumetric flow rate of 8m 3 , air supply volume 480Nm 3 / h, exhaust pressure 1.0Mpa. The air valves used in this compressor are all three-ring annular air valves. The air valve studied in the experiment is a two-stage exhaust air valve, and its vibration signal is collected by PCB EXM 608A11 sensor and NI 9234 board.

[0034] In order to explore the difference of the vibration signal of the air valve under different faults and to simulate the classification of different fault signals, the present invention divides the fault types into: a) valve plate fracture; b) air valve spring failure. We have damaged the valve plate of the exhaust valve to different degrees, and the damage method corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com